Powder Hopper Part of Closed-Loop Safe Powder Handling

November 18, 2021Comments

At Formnext…Carpenter Additive is known for material expertise in additive manufacturing (AM). A trend toward larger AM machines as the industry migrates toward volume production printing, means that a single machine may hold as much as $100,000 worth of powder. Keeping that powder prime all the away from atomization through printing, and after that through reclamation and reuse, is a major focus of Carpenter Additive, as detailed during a 3DMP booth visit.

At Formnext…Carpenter Additive is known for material expertise in additive manufacturing (AM). A trend toward larger AM machines as the industry migrates toward volume production printing, means that a single machine may hold as much as $100,000 worth of powder. Keeping that powder prime all the away from atomization through printing, and after that through reclamation and reuse, is a major focus of Carpenter Additive, as detailed during a 3DMP booth visit.

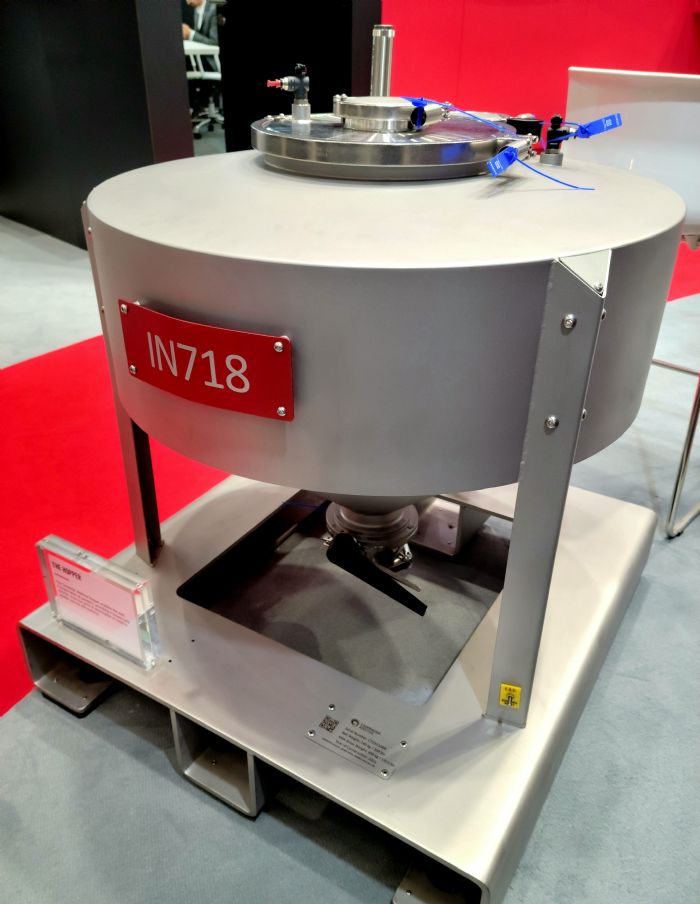

On display was a Carpenter Additive hopper, key in enabling safe transportation of powders and part of a closed-loop solution from the point of atomization to loading powder into the AM machine. Ergonomic stainless-steel hoppers from Carpenter Additive allow safe transportation of large amounts of powder, minimizing the risk of material contamination. Designed exclusively for AM metal powders, the hoppers offer material capacity to 850 kg, and allow for powder to be transported under inert conditions. This ensures that materials stay free from gaseous contaminants such as oxygen and nitrogen, and other foreign bodies that can result in failed builds and affect the final mechanical properties of built parts. The hoppers are designed and clearly labeled to be alloy-specific, with the option of a unique QR code to link to the optional software for monitoring and control traceability, and for inventory management.

The company provides expertise in developing a powder-to-part closed-loop AM ecosystem through a combination of hardware (i.e., the hoppers), software and processes. Carpenter Additive, through its PowderLife portfolio, works with AM-part producers on powder-management and -handling solutions specifically tailored to individual AM processes and facilities. The PowderLife portfolio includes material advisory services; safe powder-handling hardware for industry operators; mitigated powder-exposure risk through smart bulk transportation; data used to drive decision making during the AM process; extended powder reuse quantified through data analytics; and material optimized to deliver maximum economics.

See also: Carpenter Technology

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Welding and Joining

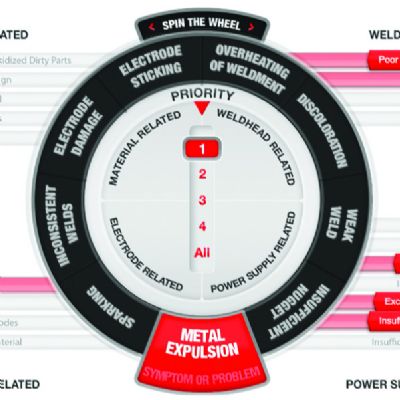

Welding and JoiningResistance Welding Troubleshooting: Seven Simple Steps

Saturday, May 18, 2024

Management

ManagementMetal Supermarkets Offers $10,000 in Scholarships for Trade ...

Tuesday, May 14, 2024

Pressroom Automation

Pressroom AutomationCobot Family Offers Precision and Speed

Tuesday, May 14, 2024