While link-motion technology does not possess the extreme capabilities of servo presses, which can be programmed at different speeds in the slide stroke throughout the cycle, the link-motion technology “fills the gap between servo and traditional mechanical presses,” says Scott Braito, director of sales at Seyi-America.

“With link motion,” explains Braito, “the upstroke is accelerated while downstroke velocity is slowed by as much as 40 percent, enabling improved drawing, forming and blanking operations, with reduced springback and extended die life. Further, by not having to slow the press, Stanco can gain as many as 10 to 12 strokes/min. for increased productivity.”

While there is a cost differential “that varies, depending on the size of the press,” payback due to increased production—as much as 30 percent—can be less than a year, says Braito.

|

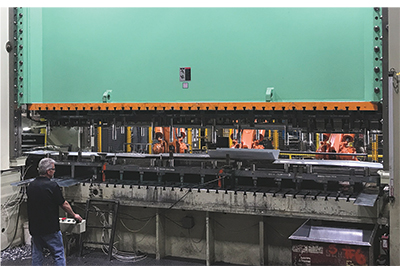

| Stanco’s Jeff McMillin is shown operating the Seyi SEL2-1100. |

Future Is Bright

While Stanco’s New Mexico operations continue to grow and add new business, Gerald Slagel says that the South Carolina plant is preparing for new arrivals as well: a Seyi SAG-660 660-ton straight-side press capable of running at 40 strokes/min. and an SEL-2 1100, the same press that’s operating in New Mexico.

“We’re seeing new business in South Carolina from the appliance and automotive segments, and while it’s difficult to project the payback on these presses, which are scheduled for installation May (SAG-660) and October (SEL2-1100), there’s definitely a need for additional equipment there at the plant,” he says.

“As we continue to grow and add new markets,” Slagel concludes, “we will continue to add employees and equipment so that our quality and on-time performance ratings remain high.” MF

View Glossary of Metalforming Terms

See also: SEYI America, Inc.

Technologies: Stamping Presses