Additive Manufacturing

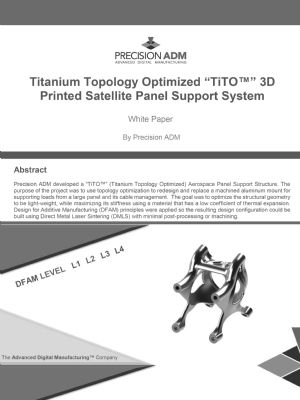

Additive ManufacturingTitanium Topology Optimized "TiTO" 3D Printed Satellite Panel Support System

LOG IN TO DOWNLOAD WHITE PAPER

LOG IN TO DOWNLOAD WHITE PAPER

Topology Optimization (TO) is a computational method or mathematical approach that optimizes a material within a given design domain or space, for a given set of loading and boundary conditions such that the resulting layout meets a desired set of characteristics. (Wikipedia).

Using topology optimization, Designers and Engineers push conceptual designs to meet and exceed the predefined design requirements. Topology optimization typically increases shape complexity to resemble “Organic-like” structures. The results are used to inspire a conceptual design that is then fine-tuned for aesthetics, function and overall performance. This design process can replace time consuming and costly design-prototype iterations and hence reduces overall design development time and cost, while improving the final product.

The purpose of the project was to use topology optimization to redesign a machined aluminum mount into an optimized light-weight structural geometry with a material that is light and stiff, but also offers a low Coefficient of Thermal expansion. The product needs to be capable of supporting loads from a panel and its cable management, and also be manufactured by Direct Metal Laser Sintering (DMLS) with minimal post-machining to keep manufacturing costs down.

Precision Adm

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted.