3D Metal Printing Experience and Tech Tour

May 22, 2019Comments

A MarketResearchFuture.com report shows the 3D metals segment jumping from $160 million in 2016 to $800 million by the end of 2022, for a compound annual growth rate of 32 percent.

A MarketResearchFuture.com report shows the 3D metals segment jumping from $160 million in 2016 to $800 million by the end of 2022, for a compound annual growth rate of 32 percent.

Such a fast-growing segment warrants an event to call its own, and as the only U.S.-based publication specifically dedicated to the industry, 3D Metal Printing magazine will once again deliver such an event in the form of its 3D Metal Printing Experience and Tech Tour. This year’s edition combines sessions led by industry experts on case-study applications, advanced materials and technologies, process improvements and more. In addition, exclusive plant tours provide opportunities to engage with company representatives and view metal additive manufacturing (AM) machines in action.

Informative Keynotes and Sessions

The event kicks off on Tuesday, August 6, with breakfast at 8 a.m., followed at 8:45 by the first of two keynote addresses. First up: Cullen Hilkene, CEO of 3Diligent. Hilkene’s talk, Metal 3D Printing: An Overview of Trends and Processes, provides attendees with an insightful perspective on today’s 3D printers and metal-AM processes.

The second keynote at 9:45, Metal AM Powder Development for the Automotive Industry, provides timely information on material innovations, with John E. Barnes, founder and managing director of The Barnes Group Advisors and CEO of TBC Training, sharing his knowledge and expertise.

Remaining Tuesday sessions include:

Remaining Tuesday sessions include:

- Transitioning From Polymer to Metal AM. Presenting: Howard Kuhn, retired adjunct professor, University of Pittsburgh;

- An Analysis of Metal AM Capabilities—Design Constraints, Economics and Scalability—and Their Impact on the Automotive Industry for Tooling and End-Use Parts. Presenting: Alex Huckstepp, vice president, business development, Digital Alloys;

- 3D Metal Printing Applications in the Automotive Industry;

- Post-Processing of 3D-Printed Metal Parts; and

- Networking Reception and Tabletop Exhibits

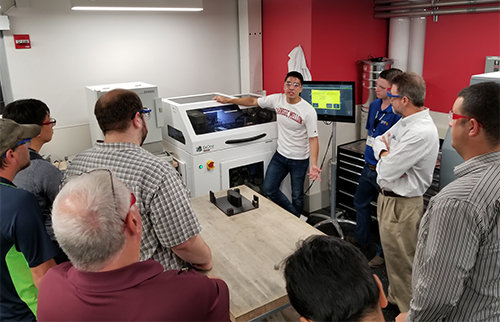

Tech Tours

Of course, not all learning takes place in meeting rooms, which is why Wednesday, aka Tour Day, includes stops at Linear AMS in Livonia, MI, and the Ford Advanced Manufacturing Center in Redford, MI.

The first tour provides an opportunity to learn and see firsthand how Linear AMS creates 3D objects from digital CAD files in a variety of metals, producing previously impossible-to-construct shapes.

The $45-million Ford Advanced Manufacturing Center, home to more than 20 printers, collaborative robots and virtual/augmented reality simulators, provides a great example of how the automotive company looks to technology to improve its manufacturing.After the tours, the 3D Metal Printing Experience concludes with lunch and a roundtable discussion featuring session speakers.

More information and to register. MF

Technologies: Additive Manufacturing, Training