The American Welding Society (AWS) recently published a new standard for metal additive manufacturing: D20.1/D20.1M:2019—Specification for Fabrication of Metal Components Using Additive Manufacturing. It provides a framework for manufacturers and suppliers to implement AM where the framework resembles other AWS D Codes. D20 provides separate qualification approaches for the PBF and DED metal AM process families. DED requirements leverage the large body of welding standards for consumables, processes, fabrication and inspection. However, challenges remain, as engineers must still define qualification requirements.

The qualification scheme, which includes the standard build design and specimen test matrix, depend on the AM process application. The scheme needs to include specimens that depend on build category (SS-NIBP, SS-IBP and DS-IBP) and material requirements, such as strength, ductility, hardness and toughness. The AWS standard requires tensile specimens, at a minimum, in three directions (longitudinal, transverse and through-thickness relative to build direction) and are representative of the thinnest (single-bead wide) and thick (multi-bead wide) walls of the structure. This new standard provides a framework for manufacturers and suppliers to implement DED. In the future, to minimize negotiations and costs, prescriptive qualification requirements must be defined for standard qualification build designs and specimen-test matrices for common process-material DED AM applications.

Digital Data Workflow Competencies

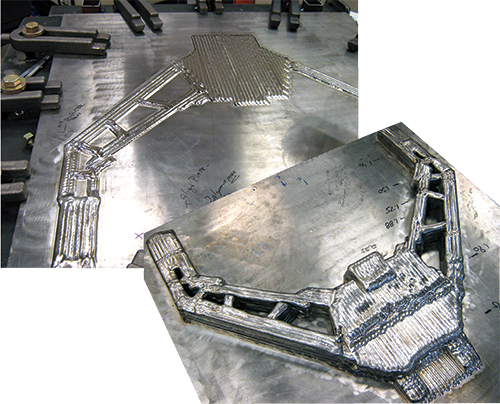

AM enables designers to fabricate parts directly from CAD files. In its simplest form, AM provides a CAD-to-part manufacturing-build process. AM systems use CAM software to solve the build plan, prepare the machine-build file, edit the build file, and download the machine build parameters and path plans. Few robot manufacturers have mature software capabilities for this AM category because robotic DED processes are new. Those that do, struggle to leverage the wide range of CAM programs (i.e., Mastercam, CAMWorks, Autodesk Fusion 360, etc.) available for parametric modeling and planning of AM builds. Most CAM software solvers configured for three- to five-axis CNC machines use G-code, the universal language of subtractive machining.

Robotic CAM provides path-planning solvers that can transfer the three- to five-axis build models into robot model environments post-process, locate the workpiece to maximize build performance of the robot(s) and determine the build-path-plan, with solutions for six- to 12-axis (or more) robotic systems. Robotic CAM software such as Robotmaster (Hypertherm, Inc.), Octopuz (Octopuz, Inc.) and Powermill (Autodesk) offer robot-agnostic solver options known to be compatible with most commercial systems.

More Ahead

The implementation of the robotic-arc DED AM process brings with it challenges. Manufacturers must develop digital data workflow competences; process feature-property requirements to design components and metrics for their business cases; qualify their arc DED AM process(es); and implement the technology into operations.

Due to the hundreds of process-consumable combinations possible with arc DED, the need for process parametric model development to maximize industry impact remains constant.

Demand for large-scale metal AM parts continues. The difference today: DED tools and process capabilities can meet that demand. As a result, look for more large-scale DED applications in the coming years. 3DMP

Industry-Related Terms: Bed,

CAD,

Cam,

CNC,

Download,

Ductility,

Form,

LASER,

Layer,

Model,

Plate,

Transfer,

UltrasonicView Glossary of Metalforming Terms

See also: American Welding Society (AWS) Headquarters, EWI

Technologies:

Dennis Harwig

Dennis Harwig

Event

Event