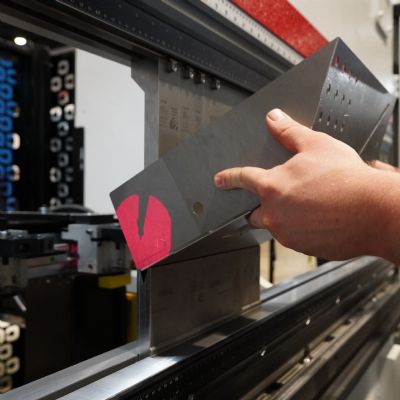

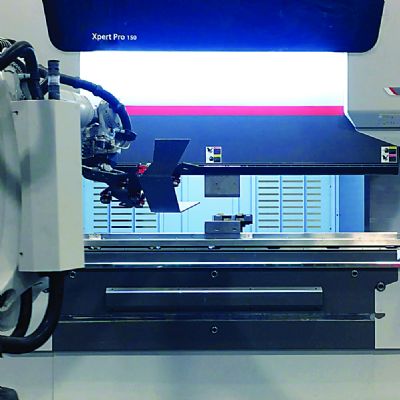

New Press Brake and Angle-Measurement System

November 1, 2015Comments

Italy-based manufacturer Gasparini, Industries, with North American headquarters in Avon, OH, introduces the X-Press line of press brakes equipped with the unique ACSG active crowning system. Designed to work with any material, since it’s not based on material charts, the ACSG system employs cylinders in the table that lift the die, while two sensors in the ram and in the table detect bowing. When the two values are equal, punch and die are at the same distance and the workpiece profile will have a constant angle across its length.

Additional features include backgauges installed either on the beam or on towers, for conical bends to 80 deg., along with sheet followers and retractable supports; and the GPS4 embedded angle-measurement system that can be used even on complex shapes and on any surface finish. Here, a sensor embedded into the die mechanically measures the profile angle within the die cavity, so as to always reach the exact value regardless of springback. This enables accurate bending of complex shapes, with Z-bends or with narrow flanges. In these cases, conventional laser sensing can be prone to errors caused by tolerance accumulation, or simply will not work.

www.gasparininorthamerica.comView Glossary of Metalforming Terms

See also: Gasparini North America

Technologies: Bending, Fabrication

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Bending

BendingRobotic Press Brake Cell Success Part of Patient Automation ...

Lou Kren Monday, February 26, 2024