Fiber-Laser Cutting Machine Tackles Material Thick and Thin

Fiber-laser manufacturer JDSU, Milpitas, CA, partnered with Amada to introduce to FABTECH attendees Amada’s Ensis-3015AJ 2-kw fiber laser that performs like a 4-kw machine. Amada personnel explained that the machine is designed to cut thick (to 35 mm) and thin work simply by changing the beam configuration electronically. With previous cutting systems, a condenser lens had to be manually changed in order to adjust the beam configuration to cut different types of materials. This versatility reportedly results from the advanced fiber-laser design co-developed by JDSU and Amada.

Fiber-laser manufacturer JDSU, Milpitas, CA, partnered with Amada to introduce to FABTECH attendees Amada’s Ensis-3015AJ 2-kw fiber laser that performs like a 4-kw machine. Amada personnel explained that the machine is designed to cut thick (to 35 mm) and thin work simply by changing the beam configuration electronically. With previous cutting systems, a condenser lens had to be manually changed in order to adjust the beam configuration to cut different types of materials. This versatility reportedly results from the advanced fiber-laser design co-developed by JDSU and Amada.

Speaking to trade-press editors, Amada president and CEO Mitsuo Okamoto noted that “around-the-clock productivity is extremely important to Amada’s manufacturing customers. Our newest fiber-laser innovation with JDSU provides customers with a major advantage because the flexibility of Ensis allows for virtually no down time during the manufacturing process, regardless of what type of material needs to be cut.”

New Family of Inverter-based Welding Machines

Esab Welding & Cutting Products introduced its new trio of Heliarc inverter-based power supplies for AC/DC GTAW and SMAW welding. Touted is the easy-to-achieve optimized arc settings that enable an operator to weld aluminum using a pointed tungsten, improving arc starts and minimizing heat input.

Esab Welding & Cutting Products introduced its new trio of Heliarc inverter-based power supplies for AC/DC GTAW and SMAW welding. Touted is the easy-to-achieve optimized arc settings that enable an operator to weld aluminum using a pointed tungsten, improving arc starts and minimizing heat input.

Heliarc’s fast-switching AC process removes the need for high frequency (used for arc starting) during welding, reducing electrical noise and the risk of interference to surrounding electronics. AC frequency control focuses the arc for narrow weld beads and faster travel speed. Used to power AC pulsed GTAW, fabricators will find the machine ideal for welding thin aluminum.

The product family comprises the Heliarc 281i, a 280-A unit for single-phase connections; the Heliarc 283i, a 280-A unit for three-phase connections; and the Heliarc 353i, a 350-A three-phase unit.

Form Tabs in a Turret Press, and Eliminate Secondary Operations

Mate Precision Tooling, Anoka, MN, demonstrated its new VariBend flexible, multipurpose CNC punch-press tool designed for forming smaller piece parts where using a press brake seems like overkill. Use it to form tabs at any angle to 90 deg. The upper forming tool is lowered onto the sheet until bending begins. Then, the flange is overbent to account for material springback. As the upper tool returns, the desired bend is formed.

Although not required, VariBend is well suited for machines with upforming capabilities and especially for machines with stroke control. Upforming allows the highest form possible for the tool design. Since the die sits lower than a forming die in a normal forming operation, the sheet lies flatter. This increases dimensional accuracy while keeping sheet marking on the bottom side of the sheet.

Better Bonded Abrasive Wheels and Discs

Cubitron II abrasive products, with 3M precision-shaped grain,

aggressively cut through more material, faster. These long-lasting

products, displayed at the 3M Abrasives booth, require less pressure,

which helps to reduce operator fatigue. Use the wheels for beveling,

scale removal and weld leveling.

Cubitron II abrasive products, with 3M precision-shaped grain,

aggressively cut through more material, faster. These long-lasting

products, displayed at the 3M Abrasives booth, require less pressure,

which helps to reduce operator fatigue. Use the wheels for beveling,

scale removal and weld leveling.

Loaded with extra abrasive material for extra-long life, Cubitron II flap discs 967A prove ideal for a wide range of jobs around the shop, including one-step grinding and finishing, weld blending and deburring.

Also available: 3M Cubitron II grinding and sanding belts and abrasive discs.

Operator-Friendly Controls Lead the List of Benefits of this New Welding Machine

Built for light-industrial applications, automotive repair and personal users, the new inverter-based Syncrowave 210 TIG welder displayed by Miller Electric Mfg. Co. can single-pass weld material as thick as ¼ in. in a single pass. The machine also marks the debut of Miller’s Pro-Set feature, which takes the guesswork out of weld-parameter setting by offering preset controls designed by Miller weld engineers. Users simply select either the DIG or Balance feature and adjust until Pro-Set appears on the display.

Built for light-industrial applications, automotive repair and personal users, the new inverter-based Syncrowave 210 TIG welder displayed by Miller Electric Mfg. Co. can single-pass weld material as thick as ¼ in. in a single pass. The machine also marks the debut of Miller’s Pro-Set feature, which takes the guesswork out of weld-parameter setting by offering preset controls designed by Miller weld engineers. Users simply select either the DIG or Balance feature and adjust until Pro-Set appears on the display.

“These operator-friendly controls provide speed, convenience and increased user confidence by eliminating the guesswork,” says product manager Andrew Pfaller.”

Field tested by Wisco Industries, Madison, WI, Wisco welding specialist Michael Pecosky says that “we only had to adjust the amperage for thickness and begin welding. Plus, the arc starts are really smooth.’’

The machine draws less power than the previous Syncrowave 200 model, allowing full welding output from 230 V while drawing less than 30 A. The result is lower installation and operational costs.

Fiber-Laser Nozzle Optimized for Stainless-Steel Cutting

Among numerous product innovations displayed at the Trumpf booth was the debut of BrightLine nozzle technology, which accelerates the cutting gas to a high velocity and, using a finely tuned set of parameters, enables cutting of stainless steel to 0.8 in. thick. The setup also proves ideal for cutting highly reflective materials such as copper and aluminum alloys.

As explained by Trumpf engineers at the booth, fabricators also can use the BrightLine nozzle to cut smaller contours than previously possible. And, small holes which previously could only be drilled now can be cut with a laser. Other benefits: spatter-free piercing, and a smooth cut surface and wider kerf to ease part removal from the skeleton.

FABTECH 2013 Set the Tone for a Bountiful 2014

FABTECH 2013 in Chicago set the tone for the upcoming year of international programming by FABTECH’s sponsoring partners. FABTECH Canada runs March 18-20, 2014 at the Toronto Congress Centre. On April 10-12, the inaugural FABTECH India, collocated with the India Institute of Welding’s Weld India Exhibition, lands in New Delhi. FABTECH Mexico takes place at the Centro Banamex in Mexico City, May 6-8.

And, last but not least, FABTECH 2014 heads south to Atlanta, GA, November 11-13. Learn more at www.fabtechexpo.com.

View Glossary of Metalforming Terms

See also: Hypertherm, Inc., Lincoln Electric Co., Miller Electric Mfg. Co., TRUMPF Inc., Mazak Optonics Corporation

Technologies: Cutting, CNC Punching, Finishing

FABTECH 2013, the largest metalforming, fabricating, welding and finishing event in North America, set records last November for numbers of attendees and exhibitors as well as for floor space. More than 40,500 attendees visited 1573 exhibitors spread across 650,000 sq. ft. of exhibits at McCormick Place to see live equipment demonstrations and compare products side-by-side to find cost-saving solutions at product displays.

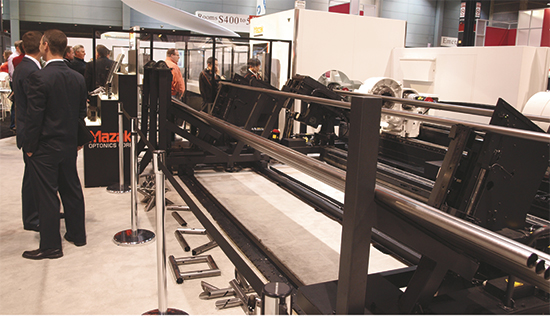

FABTECH 2013, the largest metalforming, fabricating, welding and finishing event in North America, set records last November for numbers of attendees and exhibitors as well as for floor space. More than 40,500 attendees visited 1573 exhibitors spread across 650,000 sq. ft. of exhibits at McCormick Place to see live equipment demonstrations and compare products side-by-side to find cost-saving solutions at product displays. Mazak Optonics Corp., Elgin, IL, demonstrated for FABTECH attendees its new Tube Gear 2D laser-cutting machine with high-speed capabilities for thin-walled applications. Available with a 2.5- or 4-kW resonator, the machine can process round and rectangular tube and pipe to 6-in. dia. It has a standard 5-in. servo focus torch and can make cuts at a rapid traverse rate to 6300 in./min.

Mazak Optonics Corp., Elgin, IL, demonstrated for FABTECH attendees its new Tube Gear 2D laser-cutting machine with high-speed capabilities for thin-walled applications. Available with a 2.5- or 4-kW resonator, the machine can process round and rectangular tube and pipe to 6-in. dia. It has a standard 5-in. servo focus torch and can make cuts at a rapid traverse rate to 6300 in./min. Hypertherm, Hanover, NH, used the FABTECH stage to launch the Powermax125, a new plasma-cutting and gouging system capable of cutting 1.5-in.-thick steel at speeds to 18 in./min., with capacity to 2.25 in. When gouging, the power supply enables material removal at 27 lb./hr.

Hypertherm, Hanover, NH, used the FABTECH stage to launch the Powermax125, a new plasma-cutting and gouging system capable of cutting 1.5-in.-thick steel at speeds to 18 in./min., with capacity to 2.25 in. When gouging, the power supply enables material removal at 27 lb./hr.