The Missing Link

With plenty of capacity to fabricate steel and aluminum to 11⁄4 in. thick, as well as machine heavier gauge work, “we started (in 2011) to recognize a need for cutting heavier gauge aluminum,” says Cupples. “While we could plasma-cut thicker plate, the edge-hardening resulting from the process, along with the accompanying heat-affected zone, made it difficult to further machine (edge-finish and drill and tap holes) the cut parts to meet customer requirements. And, even when laser cutting 11⁄4-in.steel on our 6-kW machines, the cut edges often were not quite up to our cosmetic standards.”

To fill that niche and once again “find the right tool for the job,” says Cupples, the firm invested in a dual-head waterjet-cutting machine (a Bystronic ByJet Smart).

“We had so many capabilities to offer at the time (before adding the waterjet machine),” Cupples recalls, “but some of the work running on the lasers and on the plasma machine were not running very efficiently. For example, for our steel-mill customers, we were plasma cutting 2- to 4-in.-thick steel, and the edge hardening made it difficult to finish-machine the parts—drill and tap holes and mill pockets. Waterjet became the missing link.”

Now, the firm sends nearly all of its work thicker than 11⁄4 in. to the ByJet Smart. Its 6-kW fiber-laser machines take on steel from 11 gauge to ¼ in. thick. “Thinner than that and we often use our high-power CO2 laser-cutting machines, with compressed air,” Cupples notes. “We’re very good at compressed-air cutting. It’s a lost art, and allows us to, with our CO2 machines, match the production costs of a 4-kW fiber laser. We didn’t see the need to go with fiber until manufacturers came out with higher-power (6 kW) machines.”

‘Steeling’ Business

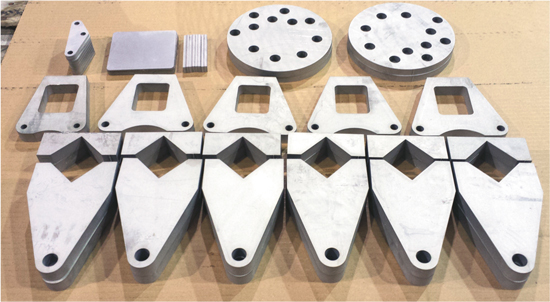

Since bringing the waterjet machine inhouse, about half of the work on its 5- by 10-ft. cutting table has been projects already being cut inhouse using other, “less efficient processes,” Cupples says, “that now run more productively on the waterjet.” For example, Cupples cites waterjet cutting of aluminum machine frames at twice the speed of machining on a bridge mill. And, for manufacturing machine side frames from 2-in. steel, the ByJet Smart carves the profiles in one step with finished edges, whereas machining the profiles required a two-step milling operation.

“In some cases the cost of waterjet cutting is the same as that for machining, but the edge quality is superior,” Cupples says. “And, in other cases we’ve been able to substantially reduce our costs, by as much as 50 percent, opting for waterjet cutting instead of machining.”

Work for new customers represents the rest of the waterjet work. “We’re getting a lot of waterjet projects from several of the steel-service companies in the region,” Cupples notes. One interesting waterjet project of note, explains Cupples, is fabricating bar stock from thick plate.

“Last year (in mid-2014) we had a need for several feet of Type 410 stainless-steel bar stock, for a customer manufacturing food-processing equipment,” he recalls, “and the mills typically only make so much of that particular product. Short on supply, we fabricated our own bar stock by waterjet-cutting 1.75-in.-wide bars from ¾-in.-thick, 5- by 10-foot plate. On that job alone we saved $11,000 compared to purchasing the bar stock—assuming we could have found it in stock.”

Precision, from Riding Close

Cupples sees the Bystronic waterjet machine as “a precision machine tool, not just a waterjet head hanging off of a typical CNC cutting table,” he says. “Compared to other waterjet machines we’ve seen, the ByJet Smart cuts with a shorter distance between the cutting head and the workpiece, around 0.060 in. This minimizes the amount of waterjet-stream divergence and optimizes cut quality—edge straightness and kerf width. The more precise the machine, the more precise our cuts.”

Bystronic rates the machine to a positioning accuracy of plus or minus 0.003 in./axis and repeatability of ±0.001 in./axis. Maximum positioning speed is 1100 in./min. (simultaneous x-y axes); the 9-in. Z axis allows a maximum workpiece thickness of 8 in.

Achieving such precision while positioning the cutting head so close to the material requires good material, Cupples insists. “We buy all stretcher-leveled material from 16 gauge to 1 in. thick, flat and stress relieved,” he says. “And for thicker plate, we buy the best-quality material we can find, SSAB plate. We completely switched over to stretch-leveled sheet and plate in 2011, working with Universal Steel (in Cleveland, OH) to develop a process to laser-cut 1-in. stretcher-leveled plate.”

Universal Steel calls its stretcher-leveler the “memory eraser.” Compared to temper-passed material, a process that changes the grain structure of the material, explains Cupples, stretcher-leveling better inhibits the tendency of the material to spring back during forming,

“Stretch-leveling elongates the grains and relaxes the material,” Cupples says. “The material is good and flat, so that the waterjet and laser-cutting heads can ride closer to the surface. And, we don’t experience the edge cracking during forming nor the edge hardening from laser cutting. This allows us to machine—mill the edges or drill and tap—at higher speeds.” MFView Glossary of Metalforming Terms

See also: Bystronic Inc.

Technologies: Cutting

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingNew Line of Wear-Resistant Waterjet Nozzles

Friday, February 24, 2023