Metal Printing Based on Arc Welding

November 3, 2017Comments

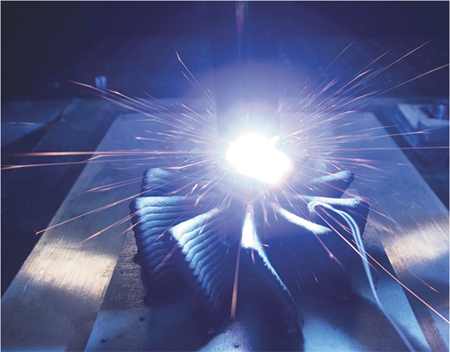

Gefertec GmbH, Berlin, Germany, unveils its 3DMP metal-printing technology at FABTECH (November 6-9 in Chicago), which, based on electric arc welding and using wire as the original material, can produce near-net-shape parts.

Gefertec GmbH, Berlin, Germany, unveils its 3DMP metal-printing technology at FABTECH (November 6-9 in Chicago), which, based on electric arc welding and using wire as the original material, can produce near-net-shape parts.

Final parts, which compare in quality to traditionally manufactured parts, according to company officials, are formed welding layer by welding layer. Reported advantages over other AM processes include no powder handling and availability of most standard materials at lower costs than powder alternatives, as well as maximum material utilization. Also beneficial, production speeds can reach 600 cm.3/hr.

3DMP technology can be used in the company’s GTarc machine, which is available as a three-axis version for parts in sizes to 3 m3 and as a five-axis version for parts to 0.8 m3. These machining centers are ideally suited for the production of complex and large parts made of steel, nickel, titanium or aluminum, according to company officials. 3DMP CAM software calculates the data of a CAD-modeled part, which enables a CNC-control unit to position the welding head with high precision. A standard CNC milling machine can handle finishing chores.

The Gtarc’s modular construction enables simple upgrades. For example, users can upgrade the three-axis version with a pan-tilt-table to obtain the five-axis version.

Gefertec GmbH: www.gefertec.de/en

See also: Gefertec Gmbh

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Management

ManagementTennessee Volkswagen Plant Votes to Unionize

Tuesday, April 23, 2024

Seyi Partners with Dallas Industries on New Showroom Additio...

Monday, April 22, 2024

Stamping Presses

Stamping PressesAida-America Launches Spanish Language Website

Monday, April 22, 2024

CNC Punching

CNC PunchingWilson Tool Appoints Semerad Chief Commercial Officer

Friday, April 19, 2024