Success in the Field

To learn how lubricant formulators are developing new recipes using additives from Lubrizol and other suppliers, we spoke with two Northeastern-U.S. companies that formulate and blend lubricants, coolants and cleaning compounds for metalformers, machine shops and others: Harry Miller Corp., Philadelphia, PA, and

“Additive suppliers have been making concerted efforts to develop replacement additives for chlorinated compounds,” says Nick Ariano, technical director at Harry Miller, “and we’ve had success in several cases for metal stampers formulating lubricants with these new additive packages.”

Describing such successes, Ariano explains how one customer recently replaced a chlorinated lubricant with a nonchlorinated product in a wire-shaving application performed to remove the outer layer of scale. And in another case, dating back to 2008, this one a Pennsylvania metal stamper forming heat-exchanger parts “with a lot of dimples and cup-shaped forms,” Ariano says, “a nonchlorinated lubricant replaced a chlorinated product and the company has had a great track record with the lubricant ever since. Payback for the new lubricant came quickly thanks to reduced waste-disposal costs, with no loss in performance.”

Severe Deep Drawing Still Requires Chlorinated Additives

While these two success stories make a great case for the metalforming industry’s efforts to become more environmentally sound, the job is far from complete. Tony Kroker, a regional manager for Harry Miller Corp., explains:

“In simpler stamping applications, we can readily substitute for chlorinated paraffins (with ingredients such as sulphurized compounds, synthetic esters and calcium sulfonate), with great success. But in more challenging applications, such as deep drawing, compounded by the growing use of tougher materials such as stainless steels and cosmetic brasses, we’ve developed water-soluble draw lubricants that actually have an increased concentration of chlorinated paraffins. In these applications, we find that while we’re not able to eliminate chlorinated products from the lubricants, we are able to switch metalformers over from straight oils to a water-soluble product and provide a more cost-effective product that’s more environmentally sound and allows for easier cleaning. And, since the lubricant contains water, in many cases the presses can run faster.”

Adds Ariano: “In these severe cases (as described by Kroker), the issue is not so much lubricity or the ability to draw the materials. The hurdle with nonchlorinated lubricants, so far, has been stickiness of the stamped parts after forming, as metalformers look to conduct post-forming tasks—stacking and destacking, assembly and the like.”

“Replacing chlorinated paraffins in severe draw applications is an ongoing project,” shares Harry Miller president Bruce Entwisle, “and the technology has a long to go to allow formulators to deliver effective and affordable lubricants. But I see the time coming—there’s a lot of research and development work going on.”

Drawing Cosmetic Brass Parts

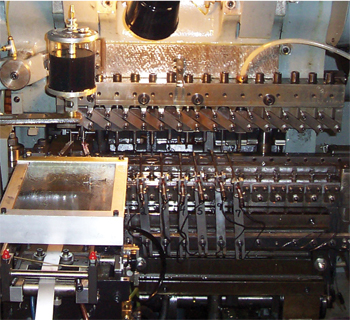

Both Harry Miller and Angler supply custom-blended lubricants, as well as cleaning compounds, to metalformer Carby Corp., Watertown, CT, a deep-draw stamper operating some 70 Waterbury Farrel and U.S. Baird transfer presses, rated to 75-ton capacity. Up until 2005, Carby blended its own lubricants, but as suppliers of compounds started to discontinue some of their ingredients, the stamper looked to outsource lubricant formulation.

Among the products Carby now receives from Harry Miller is Hamilube 9900-C, a combination of oils, EP additives (chlorinated paraffins) and emulsifiers that allows Carby to severely deep-draw brass parts (90-10 and 70-30) to a strict cosmetic-finish specification. Draw ratios can exceed 30:1 on parts the company stamps for medical devices, writing instruments, electronic products and other applications.

Carby technical support manager Gary Coviello describes one particularly challenging job—deep-drawing brass parts for ink pens. “We used to run these parts using a water-based lubricant that contained lard oil,” he says. “It satisfied our cosmetic requirements, but as an organic compound it created problems with sump life, particularly in warm weather. In some cases sump life would be as short as one week. Now, with the new water-soluble lubricant from Harry Miller, sump life typically is several weeks.”

Among the products Angler formulates for Carby is a lubricant developed for deep drawing of stainless-steel parts. “Here, chlorinated paraffin in our previous lubricant caused corrosion and staining of the parts,” says Coviello. “Angler’s lubricant (Accu-Draw 4640) solved those problems.”

For his part, Coviello is acutely aware of the EPA’s close scrutiny of use of chlorinated paraffins in the metalworking industry, and so he’s taking a hard look at “green” compounds. “We’ve just begun to test vegetable-based products for stamping some of our nickel-silver parts,” he says, noting that not only will he evaluate stamping and drawing performance but also must consider sump life, cleanability and other factors.

“The parts we’re looking at have a relatively high draw ratio (30:1) and also require a good surface finish,” he says. “We’re having problems with the chlorinated paraffin lubricant we’re currently using on this application, as it’s attacking our tooling—specifically, the binder in the carbide dies. Staining also is an issue, and we’re hoping that the vegetable-based lubricant comes to the rescue.” MF

View Glossary of Metalforming Terms

See also: The Lubrizol Corporation

Technologies: Lubrication, Stamping Presses