Brad Kuvin

Brad KuvinBurger King, Bimmers and Diemakers

December 1, 2013Comments

Mass customization has hit the automotive industry, and other industries, hard, with increased demand for cost-effectively mass-produced vehicles highly stocked with customized parts. A whole generation of choosy consumers have been raised on shopping experiences like Build-a-Bear and American Girl, where they can follow the “Have it Your ” shopping model perfected by Burger King oh so long ago. Now these selective shoppers are hitting car lots in big numbers, and they’ll undoubtedly continue to do so for the foreseeable future. Lord only knows how selective and picky their kids will be.

How does mass customization impact automotive-industry suppliers? A recent vendor tooling study conducted by Harbour Results, Inc., in partnership with the Original Equipment Suppliers Association, reveals a mountain of insights. Some of the news is good, some not so good. But there’s time to address what’s not so good, says Harbour Results president and CEO Laurie Harbour. I recently spoke with Harbour at length about her perspectives on the automotive-tooling industry, and will provide a full report next month.

The long and short of it—mass customization means more tools per platform, a lot more tools. For example, I found a presentation slide online from BMW that talks about providing 1000 bumper variations, 4000 instrument-panel choices and 488 different door panels. While this may be music to the ears of suppliers, it adds significant complexity to an already stressed supply chain. “Any negativity already present between the OEM, Tier One and tooling supplier only becomes more irritated and infectious as complexity increases,” warns Harbour.

At the same time, OEMs are launching new vehicles faster than ever before. And, production at southern-U.S. OEM facilities (where tool shops are few and far between) is expected to double by 2020. These and other factors have the industry on the precipice of what Harbour calls a “once in a generation convergence.”

What kind of reaction is needed? First, Harbour says, understand that many OEMs believe—and outwardly state—that tool shops should be happy operating at a five- to six-percent profit margin. With their heels dug in, this OEM attitude does little to promote the collaborative relationships Harbour feels must become the norm.“To meet coming capacity demands, North American tool shops must invest in new technology and in workforce development,” says Harbour. “And, they need to locate satellite facilities—at least capable of maintaining tools—in the south. It’s impossible to do this with six-percent margins. I think they need to achieve at least 10- to 12-percent margins.

“If we don’t solve this,” Harbour continues, “we will lose more of our home-based tooling industry to offshore suppliers—not because their costs are lower, but because they have the capacity.”

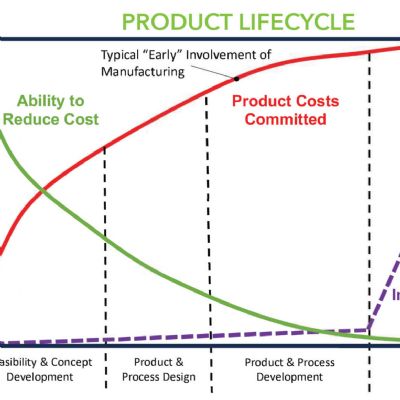

Among the solutions discussed in Harbour’s study: up-front engineering collaboration between the OEM, Tier One and the tool shop; and, of course, a shift to progressive payment plans for tooling, to provide toolmakers with the cash flow and predictability they need to efficiently manage their businesses. These steps alone promise to reduce tooling cost per vehicle by at least five to six percent, Harbour says.

“Do that and we’ll see a huge improvement and really change the face of tooling,” adds Harbour.Technologies: Management

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Management

ManagementDOL Announces Nearly $200 Million Allotted for Registered Ap...

Friday, March 1, 2024

Podcast

Podcast