GRS&S Meets Toyota Challenge

In the late-1980s, GRS&S reached out to Japanese automotive transplants, and in the late-1990s it was able to transition to supplying large value-added parts to that growing customer base. Japanese automotive customers represent 60 percent of the company’s sales. The tale of the Toyota recall speaks to the close relationships GRS&S shares with its Japanese OEM customers, as well as to its technical savvy, quick-turnaround capability and high level of teamwork among associates. The GRS&S response to the Toyota recall ultimately landed the Grand Rapids stamper, already a four-time certificate of achievement award winner, the 2012 “Celebration of Innovation: Automotive Supplier of the Year” award at the Michigan International Auto Show.

By the fall of 2009, Toyota was under the gun, needing a solution for accelerator-pedal mechanisms that could stick. Toyota researched the problem, which ran across a variety of models, and determined that insertion of small, precision reinforcement bars offered the fix. With a workable part-family design, the automaker needed to quickly move parts to dealerships across North America.

Within three days of receiving part prints from Toyota, GRS&S designed the tooling, began producing parts and had deliveries on the to Toyota dealerships. Initially, Toyota planned to have the parts shipped to its distribution centers and then forwarded to dealerships, but GRS&S compressed the process by packaging the parts and direct-shipping them to the dealerships.

A major key to project success was rapid tool design, build and tryout. “We built 11 fourslide tools to produce various precision reinforcement bars,” explains Brad Meulenberg, GRS&S tooling build department lead, “made possible through our team concept and continuous-improvement program.”

Three days from part print to production is extraordinary, as is shipment within a week to dealerships. Making that happen requires expertise in scheduling and buy-in from associates. GRS&S juggled its schedule to open up slideforming capacity and make engineers and tool builders available, and even had employees otherwise not associated with the project help out with packaging and shipping.

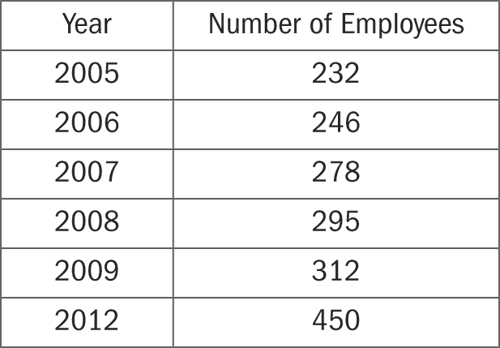

Ultimately, GRSS produced and shipped 9 million parts in seven different sizes for Toyota.In the mid-1990s, the company decided to focus on larger value-added parts and sought to develop relationships with Japanese automotive companies. With the product shift in full force, the last decade has seen GRS&S triple its sales to $100 million, with several years running of 25-percent growth. The explosive growth has netted more than 300 new employees in just the past 30 months, according to company officials.

Technology Pushes Training

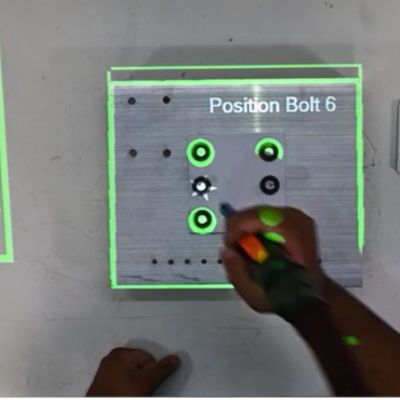

The change in part focus also brought the need for new equipment. In the past four years alone, GRS&S has spent $16 million on new equipment and technology. That includes $6.8 million invested in the first six months of FY2012. Since the late-1990s GRS&S has added 10 large presses, and in the last two years funded transfer systems to the tune of $2.5 million. Other new technologies brought in to support the paradigm shift toward larger parts and assemblies include robotic-welding cells, in-die welding and assembly capabilities, a new Plex ERP system, and software for tooling design and stamping simulation.

To keep pace with its new equipment and personnel additions, GRS&S has developed robust education and training programs. These programs, including GRS&S University, Life Long Education, internships and apprenticeships, have increased employees’ skill sets and the size of their paychecks. The company developed GRS&S University, for example, to help press-department associates learn correct techniques surrounding all aspects of press operation and safety.

New GRS&S associates begin their careers in the classroom. During their first week, each press-department associate receives 12 hr. of classroom instruction combined with 28 hr. of on-the-job training. All GRS&S associates complete at least 16 hr. of initial training, including general orientation and quality, followed by at least 10 hr. of annual recurring training.

Successful completion of GRS&S University raises the associates’ skill levels, resulting in a 4- to 6-percent pay increase within the first 180 days of employment. In 2011, the company hired 15 press operators who have completed GRS&S University and have earned the pay increase, according to company officials.

In addition, GRS&S numbers show that the university training has significantly reduced the amount of unplanned maintenance occurring in the plant, and helped reduce the number of injuries in the press department. Injury rates are well below the industry average, and the company has not had a lost-time injury in more than 2 yr.

“The University, providing instruction half-a-day, four days per week, helps a lot in training new employees,” says training manager Rose Jonaitis. “We bring in a lot of employees without experience in their field, so we can teach them with a fresh start. They are not bringing any bad habits from a prior press manufacturing job.”

|

| “This company cares about what employees think and provides opportunities for them to grow,” says Bradley Meulenberg, tooling-build department lead. “I got married three months after I started here, and the company chairman visited me personally and gave me a wedding card.” |

Though turnover at GRS&S is extremely low as compared to other metalformers, turnover does in fact occur. When the company does hire replacements or to fill new positions, “we are more concerned about the person’s attitude then his or her current abilities,” explains Dale Dulyea, safety manager and continuous-improvement manager. “GRS&S University allows us to increase the skill level of our new hires faster than we had been able to do previously.”

Jonaitis began at the company in 1976 in an entry-level position, moved on to secondary operations—now called the value added department—eventually led that department. In 2001 she took on the newly created position of training manager.

“I started at the bottom and worked my up,” she says. “I like conducting the orientation and performing one-on-one and group training. You can see the light bulb turn on, and that is fun to watch.”

Life Long Education classes—some elective, some mandatory—are held several times each month, all related to improving the company’s key performance indicators: quality, cost, delivery, safety, morale and environmental. Some classes target specialty technical areas such as welding, automation, and terms and conditions.

Homegrown Talent Recognized

|

| “Twelve years ago GRS&S hired me for setup in the assembly department. Within two years I was the lead with seven people under me,” says Troy Hendges, value-added department lead. ”I went to school at night for industrial maintenance, which the company covered. Now I run an assembly department and oversee 150 people.” |

New hires are paid commensurate with experience, and receive raises based on performance, competency and training progression.

“We are not a company that sticks by seniority,” explains Dulyea. “We are performance-based.”

Pay ranges remain competitive but allow press operators to earn significantly more than their starting hourly wages, sometimes in as little as two to three years, depending on an associate’s ability and contribution to the company. Many GRS&S toolmakers have earned journeyman status at the company, and wage progressions reflect such achievement. And 12 of the company’s engineers began as interns and have graduated to become program managers, with two having earned master’s degrees while employed at GRS&S.

|

|

“When I joined GRS&S in 1999, we had fewer than 100 employees and not many formalized rules and procedures, says HR manager Corey Hendges. “As we grew, we focused on training our supervisors to prepare them for leadership positions. Almost all of our supervisors come from hourly positions."

|

The company prefers to promote from within whenever possible. Forty-five percent of salaried associates were promoted from their starting positions at GRS&S, and four of eight senior-staff associates were promoted from within the company. Currently, 50 percent of the hourly workforce has been promoted to higher positions with higher wages. Also, each year, performance reviews lead to wage adjustments. For example, in 2012, 70 percent of associates have received 5 percent wage increases, 15 percent received adjustments from 6 to 10 percent, and 5 to 10 percent of employees received higher adjustments, according to company officials.

Benefits and wages at GRS&S are competitive with similar Western Michigan businesses. Benefits include 401(k) matching, medical and life insurance, holiday and vacation pay, attendance bonuses, and gain sharing—paid quarterly—based on company profitability.

When GRS&S describes itself as a performance-based company, it is performance that determines promotions and layoffs, according to Dulyea.

|

| Training manager Rose Jonaitis: “ We bring in a lot of employees without experience in their field, so we can teach them with a fresh start. They are not bringing any bad habits from a prior press manufacturing job.” |

“Seniority has its place for vacation time,” he explains. “But at GRS&S, when layoffs occur we will not line our people up on a scale of seniority and start at the bottom. We distinguish between our best performers, good performers and low performers.”

Cross Training via Mini-Companies

Pressroom Mini-Company at GRS&S

Officer: Pressroom supervisor

Quality Officer: Quality associate assigned to interact between the press department and its external customers, thus becoming familiar with parts and issues.

Tooling Officer: Toolroom lead, works in close concert with the press department lead, ensuring close communication.

Engineering Officer: Engineer assigned to work with the press department to improve communication and reduce production-launch issues.

Scheduling Officer: Pressroom scheduler interacts closely with the other officers to minimize communication problems.

|

Vice President Began as a Co-Op

Dan Armock, vice president—advanced engineering development, is an 18-yr. GRS&S associate who began his tenure performing summer work as an engineering co-op. He joined GRS&S full-time as a project engineer after college, moved up to pressroom manager, eventually became engineering manager, and then assumed his current position in June of 2011. Benefitting from the company’s tuition-reimbursement program, Armock received a master’s from Western Michigan University— one of the first to graduate with WMU’s advanced business-engineering combination degree. Dan Armock, vice president—advanced engineering development, is an 18-yr. GRS&S associate who began his tenure performing summer work as an engineering co-op. He joined GRS&S full-time as a project engineer after college, moved up to pressroom manager, eventually became engineering manager, and then assumed his current position in June of 2011. Benefitting from the company’s tuition-reimbursement program, Armock received a master’s from Western Michigan University— one of the first to graduate with WMU’s advanced business-engineering combination degree.

“For each of the progressions, my pay scale increased,” Armock says. “When I talk to new associates, I tell them: ‘Show up on time, work hard, try to contribute and be positive, and you can go anywhere in the company.’

“We understand that people may not come in with the perfect skill set,” Armock continues, “but if there is a willingness to learn, the company will help. Visitors to GRS&S are amazed at the culture here.”

|

These officers meet weekly to discuss issues and solve problems, ensuring that the press department looks ahead to achieve its goals. Additionally, the entire press department mini-company meets weekly to review corporate information, review mini company KPI scores, review quality and safety issues from the prior week, conduct any necessary department training, and break up into small groups for problem-solving.

While many organizations seek a cross-functional workforce, GRS&S goes the extra mile. The company operates several cross-functional teams referred to as mini-companies.

“A mini company is a term and activity we learned from a consultant, Kiyoshi Suzaki, in the early 1990s,” explains Dulyea. “He visited GRS&S quarterly for several years, and helped us develop the mini-company concept and improve our lines of communication. Our goal was to have every production department run as a company; thus strengthening customer-supplier relationships and providing a vital check-and-balance mechanism.”

Each mini-company at GRS&S has specific internal and external customers, with the goal to ensure that no mini-company passes along a defect to any downstream customer. Another goal: improve the lines of communication—giving each associate a place to voice concerns and opinions.

Each mini-company meets weekly—with all associates participating —to review key performance indicators and conduct problem solving. A minimum of three officers from manufacturing, quality and technical departments lead the mini-companies (see Pressroom Mini-Company at GRS&S sidebar), and each week all mini-company officers meet to share best practices, review the key performance indicators and discuss implemented improvements. Each quarter, mini-companies meet with management in what are called bankers meetings. Here they review results relating to the key performance indicators and discuss plans to improve. These meetings also allow for requests for capital expenditures.

|

Quality Training Brings Quality Career

Jennifer Robinson, management representative-supplier quality, started at GRS&S in 1999 in the shipping department. Jennifer Robinson, management representative-supplier quality, started at GRS&S in 1999 in the shipping department.

“From the beginning, I wanted to learn everything I could,” she says.

That willingness to learn propelled her to a shipping lead position. Interested in a posted quality position, Robinson was recommended for the job by her boss. The transfer to quality led her, through the company’s tuition-reimbursement program, to college courses where she is working toward a degree in quality engineering.

Responsible for more than 100 GRS&S suppliers, and also an ISO and TS representative, Robinson’s compensation has gone from hourly to salaried, which doubled her pay.

“If you have the desire and drive, there is als room to grow here,” she says. “There is openness here. You see the president and chairman of the company on the shop floor, which never happened at my former employer. And we have meetings where management explains where every dollar goes.

“And, there are no time clocks…are you kidding me?” Robinson exclaims. “That is a level of trust on behalf of the company that I want to keep.” |

Mini-company officers generally are promoted from within their areas. Officer positions allow associates to increase leadership and management skills, which result in increased wages. To help officers grow into their positions, the company offers a variety of internal and external leadership courses.

To further communicate best practices within each mini-company, GRS&S holds an annual trade show. Here, mini-companies within each building videotape of some best practices and new technologies, which are then viewed by members of other mini-companies at the trade show to promote idea-sharing.

Associates receive other perks that make GRS&S an attractive place to work. They don’t bother punching in and out, as the company has eliminated timeclocks. Associates simply write their hours on personal timesheets that are turned in to supervisors at the end of the week. The company also provides loans whereby associates can purchase new home computers. Money is repaid through interest-free payroll deductions. As many as 25 associates annually take advantage of this program, and the company benefits as well—approximately 90 percent of associates must interact with a computer at one time or another during the work day, so computer proficiency adds work knowledge.

Company Culture Fosters Improvement

The GRS&S World Class Idea program, based on the Toyota Suggestion System, taps the knowledge of associates to drive continuous improvement. Company-wide meetings held every six weeks promote the program and review department performance against continuous-improvement goals. The meetings also showcase examples of recently implemented improvements to help generate more ideas.

In FY2011, GRS&S implemented and documented 7068 individual improvements related to its key performance indicators, resulting in a cost savings or avoidance of more than $800,000. Placing that in context, the U.S. manufacturing-company average is less than two implemented ideas per person annually, while in Japan, proactive companies may receive 75 implemented ideas per person per year, according to GRS&S management. More than 90 percent of GRS&S employees have forwarded improvement ideas which, according to Dulyea, do not have to be earth-shattering to make an impact.

“When I first started here 19 years ago, I worked in the shipping department,” says Dulyea, recalling his first experience with the company’s continuous-improvement program. He now runs some of the company’s World Class Idea meetings. “My job at the end of the day was to go around the plant and empty trash cans. Instead of emptying all the cans, then going back to the cabinet to get trash bags and travel around the plant again to place new bags back in the cans, I just placed a handful of bags in each trash can so I would only have to go around once. I did that, frankly, because going around twice annoyed me. I told my boss, ‘I hope you don’t mind, but I put extra bags in the cans so I don’t have to waste 10 minutes going around the plant twice.’ He said, ‘That is a world-class idea.’ I had no idea what that meant. But those are the types of improvements that, over time, really make this place run efficiently. That is the whole point of the program: getting people to think about improving their process.”

“We’re averaging more than 25 implemented ideas per associate for the each of the last 10 years, adds Zawacki. “This positive culture and our workforce-development programs have attracted a customer base that many would envy, and has allowed us to develop a strong, nationally recognized safety program, eliminate time clocks and maintain high quality standards.”

For example, Dulyea explains, the pressroom mini-company as an annual goal of 28 fully implemented improvements per person.

“We track these and review progress at both our quarterly bankers meetings and at our company-wide WCI meetings, held every six weeks,” he says.

The number of suggestions approved ties to a dollar amount given out at an annual company holiday party. Buy-in on programs such as World Class Idea is a big reason why GRS&S has remained profitable while averaging 1 to 2-percent cost downs annually (value-added only) on existing sales.

GRS&S fosters goodwill among associates in other s, too. Weekly department meetings pass along management information, review department performance, promote problem solving and allow feedback from associates. This kind of communication lets associates know that they have a voice in company matters. In addition, quarterly business reviews share profit/loss statements, information on new business contracts, safety performance and a general ‘state of the company.’

“Communication is critical to building trust,” says Dulyea, “so associates are als provided with company information. Very little is sacred here.” MF

See also: Lear Corporation

Technologies: Management, Safety, Training

Lou Kren

Lou Kren

Training and improvement programs, combined with a successful market shift, mean bright days for this Western Michigan metalformer How bright? Since FY2009, when sales dropped by 26 percent in the midst of a general manufacturing freefall, GRS&S rebounded with annual sales increases averaging 29 percent. The growth continues with the company launching five major product families in FY2012, totaling 330 parts with many slated for hybrid and battery-powered vehicles.

Training and improvement programs, combined with a successful market shift, mean bright days for this Western Michigan metalformer How bright? Since FY2009, when sales dropped by 26 percent in the midst of a general manufacturing freefall, GRS&S rebounded with annual sales increases averaging 29 percent. The growth continues with the company launching five major product families in FY2012, totaling 330 parts with many slated for hybrid and battery-powered vehicles.

Dan Armock, vice president—advanced engineering development, is an 18-yr. GRS&S associate who began his tenure performing summer work as an engineering co-op. He joined GRS&S full-time as a project engineer after college, moved up to pressroom manager, eventually became engineering manager, and then assumed his current position in June of 2011. Benefitting from the company’s tuition-reimbursement program, Armock received a master’s from Western Michigan University— one of the first to graduate with WMU’s advanced business-engineering combination degree.

Dan Armock, vice president—advanced engineering development, is an 18-yr. GRS&S associate who began his tenure performing summer work as an engineering co-op. He joined GRS&S full-time as a project engineer after college, moved up to pressroom manager, eventually became engineering manager, and then assumed his current position in June of 2011. Benefitting from the company’s tuition-reimbursement program, Armock received a master’s from Western Michigan University— one of the first to graduate with WMU’s advanced business-engineering combination degree.