Technology-Driven Operational Enhancement

Given the impact and automation-related benefits being driven through technology, it’s critical to investigate ways in which metal formers can leverage business-operations solutions. At Baker Tilly, our team works with clients on both ends of the spectrum, from planning and implementation, to providing long-term support, to helping manufacturers make incremental changes to increase efficiency, and in many cases, steered many entirely paper-based floor shops to leading-edge cloud-based platforms. Manufacturers that first leverage enterprise resource planning (ERP) and material requirements planning (MRP) software are more successful with industrial internet of things (IIoT) initiatives.

To transition to a smarter factory, manufacturers must introduce new processes in phases, in order for managers to determine what makes the most financial and operational sense. It can be a time-intensive process, but necessary for an effective changeover.

Further, companies interested in updating their systems should evaluate a few different solutions, including ERP, MRP and IIoT. In many cases, it is crucial to consider the longer-term system architecture integration, and then prioritize. Doing so can ease the transition, and help managers focus on areas with faster returns, while requiring far less reconfiguration with subsequent projects.

ERP, MRP and IIoT

"Organizations today need to look across their enterprises and work toward developing key strategic scenarios that will help accelerate recovery and movement into the next normal."

An ERP system ensures that a manufacturer’s entire team works from one plan, regardless of where the teammates are located. It means, for instance, that the finance, sales and production teams all know simultaneously what is happening in the plant, and whatever information is shared will help them separately prepare for a market upturn or downturn.

An MRP system can work with an ERP system, or can be used on its own. Regardless, we have seen how supply and demand have created serious issues during this pandemic, with some manufacturers struggling to keep up with a jump in orders, while others are drowning in supplies they cannot use, since demand has dried up. Having a flexible MRP software in place can help companies more readily make the necessary adjustments when demand fluctuates, and communicate across the sales, materials, purchasing and finance teams. Connecting the MRP to a vendor portal can alert the supply base, which can react faster to a ramp-up or downturn in production. Further, best-of-breed MRP can plug into industry market data, allowing a metal former to react to potential demand changes further upstream than just the immediate customer. Manufacturers need an MRP solution that makes reacting to change easy and as automatic as possible, instead of cumbersome confusing systems with opaque formulas.

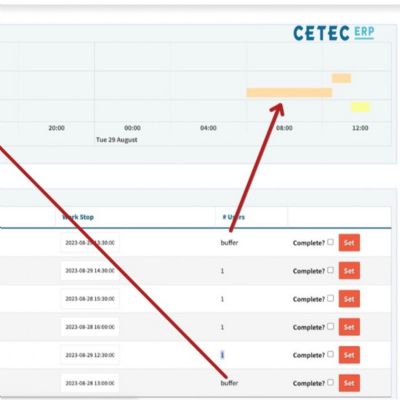

Another issue we have seen where technology can help: accurately tracking what is happening on the plant floor. If a company adopts the mindset of IIoT, managers can remotely monitor activity on the shop floor through data collected by sensors mounted to production equipment. They can, for example, see how many machines are operating at a given time, how many parts per minute a machine is making, etc. And, they can receive alerts regarding machine status, to allow leadership to respond to issues quickly, and minimize the impact to the rest of the operation.

A Three-Step Planning Process

Regardless of the technology, its purpose is to help a company grow and thrive. The system must make strategic scenario planning easier when preparing for an unforeseen crisis. When creating such a plan, the company management team should define key operational and strategic elements that would require specific actions, depending on the situation, and should consider a variety of timeframes, viewpoints and reactions.

We recommend following a three-step process when making a plan:

1. Create plausible scenarios unique to the company, and then model the impact of each on the business. Each scenario requires a different strategic response. Managers also should consider the relative likelihood of each occurrence, working within the parameters of best case, worst case and most likely to happen. Identify a list of key leading indicators, and prioritize them alongside a set of assumptions, performance ranges and triggers. With the scenarios established, conduct a modeling exercise to simulate the financial impact of the leading indicators on each scenario. Each scenario should have its own profit-and-loss statements, balance sheets and cash-flow statements that can be compared with the others.

"Regardless of the technology, whether ERP, MRP or IIoT, its purpose is to help a company grow and thrive."

2. In the second planning step, with the scenarios defined and leading indicators quantified, managers should define a portfolio of potential strategic actions, organized around themes relevant to the company’s financial survival and recovery during a crisis. Those themes should include revenue sources, supply chain, workforce, processes and technology. Each theme should help the company address and highlight actions required to respond to the situation in order to preserve and eventually enhance the company’s value. They should have short- and medium-term objectives, and related strategic actions.

The portfolio of actions for each scenario should establish a roadmap for the business to stabilize the current financial situation, and then prepare for the post-crisis “new normal.” The pandemic presents an elevated need to be on a robust, modern software and hardware system. This holds true especially as security breaches become a larger threat and onsite support becomes more difficult to access due to health and safety concerns.

Consider implementing technology solutions such as ERP, MRP and IIoT, to help change the workforce landscape. These solutions can connect humans, machines, sensors and data, often resulting in manufacturers needing fewer workers in certain areas, literally and figuratively. COVID-19, in particular, means having only so many people on the plant floor, which is where IIoT helps, as it can share production-related data at any time, with anyone, without manual intervention. A company with an MRP system in place when the pandemic hit, already had virtually connected teams (sales, materials, purchasing, finance, etc.), and office staff easily transitioned to working remotely. With that type of solution, a company quickly can adjust production planning, purchasing and sales forecasts from anywhere, and simply communicate any changes to the proper stakeholders. Such connectivity also enhances competitiveness, allowing employees to readily reach out to customers and prospects to share real-time up-to-date information on pricing, inventory, delivery times, etc.

3. Proper planning and execution only will help metal formers in the long term if they engage the third and final step in strategic scenario planning—monitoring the recovery, and refining strategic responses as needed. In a crisis such as the pandemic, the situation is fluid, dynamic and unpredictable. The appropriate reaction can change rapidly. Again, employing an ERP or MRP system will enable immediate communication of any changes to the appropriate stakeholders, whether internal, e.g., management, or external, e.g., suppliers and customers. During this planning stage, companies should enable their systems with proper alerts and backup processes to react to the new scenarios.

A manufacturer’s flexibility and responsiveness will determine not only its survival, but also its long-term outcome. By implementing an agile and supportive ERP, MRP or IIoT platform for manufacturing with remote access, a company can position itself to grow into the future. Embracing technology now will set up an organization to attract and retain expanding customers tomorrow. MF

See also: Baker Tilly Virchow Krause, LLP

Technologies: Management

Edward Mulford

Edward Mulford Erich Bergen

Erich Bergen According to the National Association of Manufacturers’ outlook survey for the second quarter of 2020, 98.7 percent of manufacturers either continued or only temporarily stopped operations. Respondents also showed flexibility in their reaction to the pandemic, with nearly 22 percent “retooling” to produce personal protective equipment, 67 percent reengineering processes to reflect new safety protocols and 12 percent completely reevaluating their company’s mission.

According to the National Association of Manufacturers’ outlook survey for the second quarter of 2020, 98.7 percent of manufacturers either continued or only temporarily stopped operations. Respondents also showed flexibility in their reaction to the pandemic, with nearly 22 percent “retooling” to produce personal protective equipment, 67 percent reengineering processes to reflect new safety protocols and 12 percent completely reevaluating their company’s mission.