Overlay Wire for Severe Abrasive Wear and Moderate Impact

March 9, 2020Comments

Ssab Hardox Corp. has introdued Duroxite 200 Wire, a flux-cored welding wire, like other Duroxite products, made of abrasion-resistant material deposited on top of mild steel or Hardox wear plate to create a wear-resistant compound material.

Ssab Hardox Corp. has introdued Duroxite 200 Wire, a flux-cored welding wire, like other Duroxite products, made of abrasion-resistant material deposited on top of mild steel or Hardox wear plate to create a wear-resistant compound material.

Used mainly for capping, routine maintenance or repair work, the wire can be welded on mild steel, quenched and tempered steels, cast materials, and stainless steel, and reportedly is simple to apply onsite or in the workshop. One common application: capping the weld when joining complex carbide overlay plates such as Duroxite 200 and maintaining the same service life as the plates. Duroxite 200 Wire is self-shielded and welded with an open-arc process using manual or machine welding.

It forms an overlay with primary chromium-rich carbides and co-existing refined multi-alloy carbides, which provide a good combination of wear and impact resistance. When welding multiple layers of the wire, the same wear resistance is guaranteed from the surface down to 75 percent of the overlay thickness.

Typical applications include sand and earthmoving equipment such as buckets and teeth, railway ballast tampers, dredge buckets and lips, dragline buckets, coke hammers, rippers, sizing screens, crushing equipment, brick-industry components, muller tires, catalyst lift pipes, pump impellers, fan blades, rockwool rolls, and wear plates operating at high temperatures in the steelmaking industry.

View Glossary of Metalforming Terms

See also: Ssab Hardox Corp.

Technologies: Materials

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Materials

MaterialsChemcoaters Launches InterCoat ChemGuard for Body-in-White S...

Tuesday, April 6, 2021

Materials

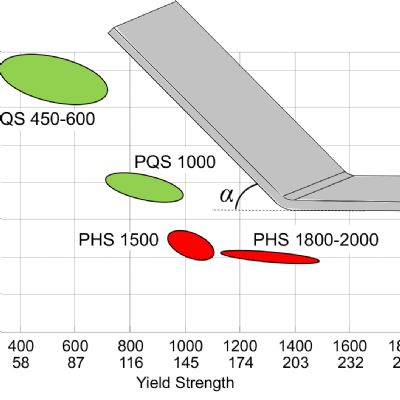

MaterialsHeating Helps Forming, Part 1: Hot Stamping of High-Strength...

Eren Billur Wednesday, July 29, 2020

Materials

MaterialsStamping High-Strength Stainless? Coating is a Tool Lifesave...

Lou Kren Wednesday, July 29, 2020