Peter Ulintz

Peter UlintzModern Four-Slide Technology

May 21, 2019Comments

This month’s article concludes a three-part series on four-slide forming processes. Following articles on slide forming processes (April) and four-slide tooling (May), this month we look at modern four-slide controls and servo-drive technology.

Today hundreds, potentially thousands, of traditional mechanical four-slide machines dating back to the 1960s (or earlier) still operate, and traditional slide forming remains an effective process for manufacturing small, intricate parts. Even so, there are limitations.

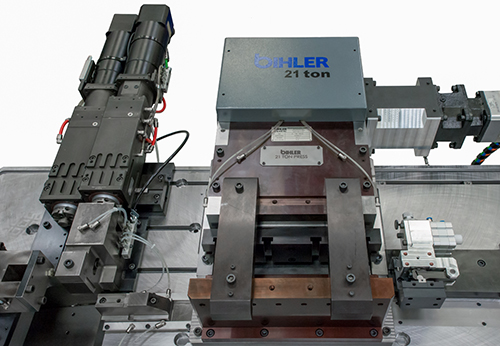

Modern four-slide forming equipment includes servo-driven systems.

For example, complex mechanical motions and timing sequences require setup technicians and operators to have more training and higher skill levels than necessary for a conventional press. Moreover, the setup process can be very time-consuming as it calls for the following:

- Combination of standard and special cams to attain the slide stroke and timing necessary for forming the part around the center tool;

- Slide-tooling adjustments to attain part quality, requiring the setup person to advance or retard the timing on the cam;

- Feed-length setting, recognizing that it may require further adjustment based on the amount of material stretching;

- Press-station adjustment for achieving proper die-shut height, the distance between the bottom of the ram and the top of the press bed or bolster at the full-closed position (e.g. 270-deg. die-shut height for a 180-deg. feed);

- Passing of the wire or strip through the feed mechanism and into the first station of the progressive die, if required;

- Cycling of the machine by hand and engaging the feed when the press is at the full-open position;

- Continued cycling of the machine by jogging or turning the machine by hand, through the die and to the cutoff station, where adjustments are made and lengths of cutoff blanks verified;

- Continued jogging or turning of the machine by hand, going through several cycles of forming to make a few parts; and

- Tooling adjustments (refitting or regrinding may be necessary) to bring parts within tolerance.

The lack of modern controls and servo technologies restrict setup time, part complexity and production efficiency when using mechanical slide forming machines.