CT is the latest, and perhaps the most powerful, development in the modern era of nondestructive testing—quite a boast, but let’s see why.

|

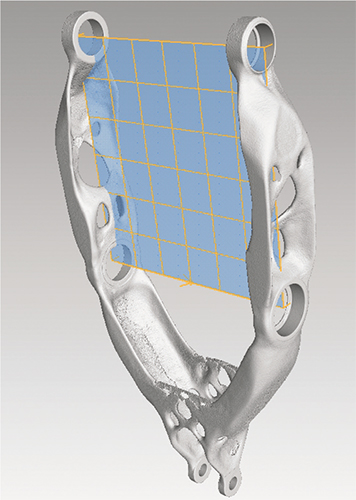

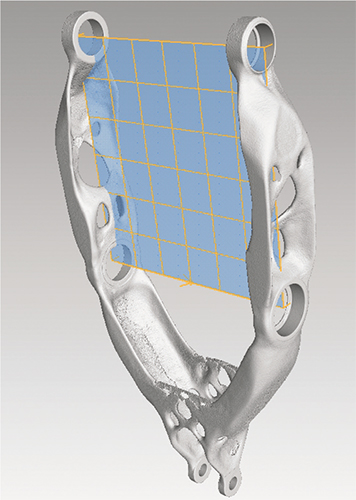

| CT scanning allows for rapid, precise inspection without the need to destroy parts or disassemble components. Here, a bell crank is inspected via this method. |

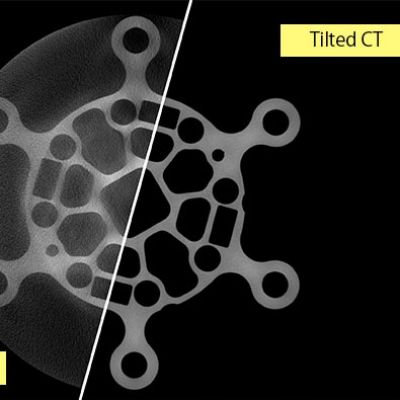

A CT scan produces a 2D density map of a cross-sectional slice of an object’s interior. A 3D volumetric model can be produced from many of these views taken at different viewing angles and then reconstructed using a computer. Many 2D slices can be combined by powerful software to produce a 3D image of practically any object . This is critical for any application where a manufacturer wishes to see inside of an object without destroying it.

Today’s industry CT scanners offer advanced functional capabilities that provide extremely valuable data for initial prototyping and for optimizing production processes. They can detect potential part failures, even on larger parts. This had never before been possible, but is now because CT-scanning techniques produce crystal-clear images that are superior to other modality choices. These images can assist manufacturers in a comprehensive failure analysis of parts and enable them to identify finite cracks and inconsistencies from part to part. Substrate bonding issues, uneven material flow, and density and porosity problems also can be detected through the accuracy of CT images. CT screening helps improve productivity by eliminating issues that potentially cause post-production problems.

CT Versus Other NDT Techniques

Popular nondestructive-testing (NDT) techniques used in AM include metrology, ultrasound and x-ray. How do they measure up? Metrology, the study of measurement and a basic requirement in any field of science and technology, is expected to enforce, validate and verify predefined standards for traceability, accuracy, reliability and precision. All of these factors affect measurement validity. Without destructive testing, full metrology has been performed only on components’ exterior dimensions. A highly detailed component would be inspected using a time-consuming coordinate-measuring machine, touch-probe process or vision system to map exterior surfaces. Past internal-inspection methods required a 2D X-ray of the component or NDT.

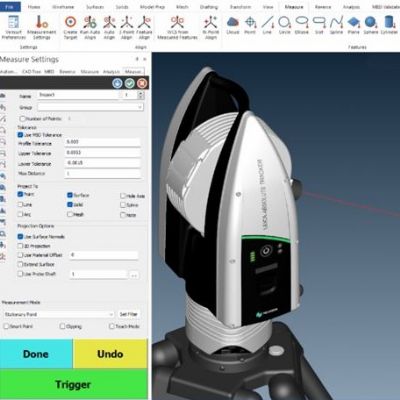

The latest CT-scanning systems combine CT scanning with metrology measurements in a single scan, as part of a single simple step, an important development for AM companies.

Ultrasound imaging, also called ultrasound scanning or sonography, employs a small transducer (probe) and ultrasound gel placed directly on the object to be imaged. High-frequency sound waves transmit from the probe through the gel and into the object. The ultrasound process produces an electromagnetic field, with the induced field in the part measured. A discontinuity shows up as a blip on the screen, allowing users to find tight cracks on a surface that may be difficult to impossible to see.

Though popular in manufacturing, ultrasonic testing, requiring a small transducer and a control unit to emit the signal, then coupling it directly to the part, can be a messy and complicated process.

Often a Better Way to Inspect

Until recently, examining interiors meant taking apart an assembly or cutting open a single part. Doing so introduces certain artefacts to the inspection. How can you know exactly how a part interacts in an assembly when just looking at the separate, individual components, and how can you quantify that a part has been made to tolerance if it is now in two or more pieces? The ability to virtually slice through a part or visualize the internal workings of an assembly with the individual parts, in situ, provide the inspector with much more useful information.

CT scanning often provides the best solution for applications requiring visualization of an object’s internal features or high-resolution inspection for defects or inclusions. And, increasingly it is applied to metrology applications, such as CAD comparison, nondestructive internal measurements (for wall-thickness measurement) and reverse engineering.

And, the latest generations of evaluation software enable significant improvements in CT-scanning visualization and verification methods. There’s almost no limit to the types of tasks to which CT systems can be adapted.

For example, some typical flaws in the powder-bed-fusion process include porosity, lack of fusion, balling, surface roughness and microstructural issues. CT scan data allow rapid identification of these issues, thus reducing production time and increasing productivity. CT scanning also enables internal structures to be seen in their functioning position. And, some software programs for industrial CT scanning allow for measurements to be taken from the CT dataset volume rendering, useful for determining the clearances between assembled parts or simply a dimension of an individual feature.

CT scanning also detects density variation, embedded features, organic part design, dissimilar metals or materials, and surface finishes more readily than other NDT techniques.

Faster, More Rugged and Accurate than Ever

One common misconception about CT scanning: It’s too slow. In fact, advances in CT scanner design and technology over the past few years have eliminated this problem. Today’s scanners have improved in speed and efficacy, more than doubling their production value. Also, stringent design and production standards have resulted in systems that withstand the rigors of high-volume use.

CT scanning resolution also has improved significantly, resulting in images that detect even the most minute flaws. Many scanners provide resolutions to 5 µ or less. Also, today’s CT software is easier to use, with improved workflow design and advanced protocols to enable faster and more accurate reproductions.

Another common misconception: You can’t perform metrology using CT scanning. Though true in the past, today’s scanners conduct precise measurements instead of just looking for defects.

But what about cost? Scanner costs have dropped significantly in recent years, with CT inspection systems now available in many configurations. AM professionals can find systems that meet production and budget needs. 3DMP

See also: Yxlon Sales & Service

Technologies:

Jeffrey Urbanski

Jeffrey Urbanski As additive manufacturing (AM) moves quickly from rapid prototyping to a valid process for reliable low-volume production parts, computed-tomography (CT) scanning technology becomes increasingly important as an inspection and nondestructive-testing platform. However, many AM providers remain unfamiliar with how CT can help improve and monitor production quality, or they have misconceptions regarding CT capabilities and the cost of incorporating it into their processes.

As additive manufacturing (AM) moves quickly from rapid prototyping to a valid process for reliable low-volume production parts, computed-tomography (CT) scanning technology becomes increasingly important as an inspection and nondestructive-testing platform. However, many AM providers remain unfamiliar with how CT can help improve and monitor production quality, or they have misconceptions regarding CT capabilities and the cost of incorporating it into their processes.