Electric Shakers Minimize Operating Costs, Eliminate Maintenance Requirements

July 1, 2009Comments

Magnetic Products, Inc. (MPI), Highland, MI, manufactures

|

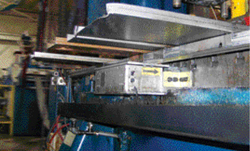

Toledo Tool and Die (TTD) recently installed several Model M-50 shaker conveyors at its facility in Toledo, OH, after using pneumatic shakers for several years with limited success. The pneumatic units shakers required frequent maintenance, were noisy, and performed inconsistently.

Says Larry Kubiak, TTD production manager, “The M-50 electric shaker has proven to be more reliable than any other shaker we’ve seen. We will continue to replace our pneumatic units with MPI electric shakers until we have one on every press.”

MPI: 800/544-5930; www.mpimagnet.com

See also: Magnetic Products, Inc.

Technologies: Pressroom Automation