Improved Machine Availability

“It’s our experience that the leveling unit defines the quality of each individual system,” says Rünker. “Good, reliable and regular maintenance of the leveling cassettes satisfies our requirements, as it is the only dependable way to avoid downtime.”

With leveling tools requiring rework from time to time, B+S handles this as an after-sale service at its factory in Siegen, Germany, and guarantees short delivery times if leveling cassettes are replaced.

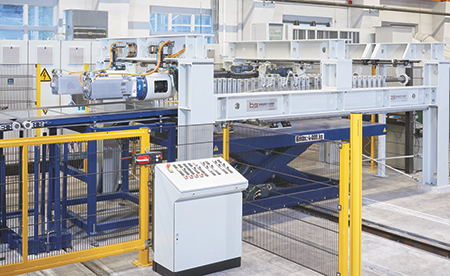

To facilitate faster cassette inspection and replacement, Schnutz developed quick-change leveling cassettes. “These improve accessibility and, therefore, the maintenance can be reduced,” says Baral. “During maintenance,” he explains, “the operator removes the cassette completely from the leveler and positions it on a rack enclosed on a robust welded-steel-frame. A lifting gear picks up the cassettes so that they can be inspected and then reworked if necessary,” leading to minimal downtime and improved machine availability.

Drum Shears Accelerate Operation

|

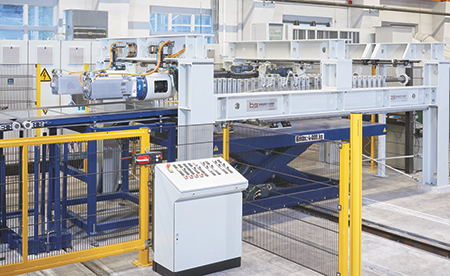

| The new line features an integrated swing-arm stacking machine to protect sheet surfaces. The swing arms are powered by three-phase servomotors with a controlled force-velocity curve. |

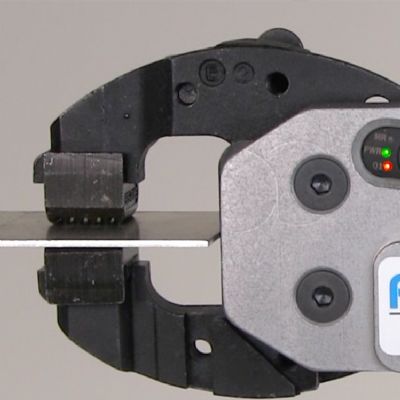

Once unwound and leveled, strips are cut crosswise into metal plates. “We equipped the system with a drum shear to speed up the operating process,” reports Baral. “The material runs continuously and, therefore, a looping pit is not needed.” Not only does this make the system more compact, it also reduces the cost of footings. Clearance between the two blades, for the drum shear, adjusts automatically according to material-strength and thickness data, which is entered at the main operating console. This prevents unnecessary user errors while also improving operating speeds.

“The benefits of quick and individual adjustment for varying material properties are obvious,” Rünker explains. “It cuts tooling times and the cost of auxiliary process times, while allowing for quick corrections and intervention during production in case of any deviation from the customary quality standard. It also significantly extends the lifecycle of the cutting tools.” Additionally, the modern electronics in the drum shear and B+S’s proprietary software guarantee enable the narrow length tolerances requested by Martinrea Honsel.

Surfaces Protected

The Companies Martinrea Honsel GmbH, founded in 1908 by Fritz Honsel as Fritz-Honsel-Gravieranstalt und Formenmacherei in Werdohl, Germany, became part of Martinrea International, Inc. in 2011. Since then, Martinrea Honsel has provided light-metal products to the automotive industry. The company has approximately 3000 employees worldwide, working in 10 plants in Germany, Spain, Brazil, Mexico and China. Burghardt+Schmidt GmbH manufactures machines and systems for the cutting and leveling of metal strips. Its equipment, custom-built to suit the needs of customers, draws from the company’s experience in the thin-strip sector. The machines and lines are developed and manufactured at its headquarters in Remchingen, Germany. Schnutz GmbH, part of the Burghardt + Schmidt Group since 2014, traces its roots back to 1846 when Martin Schnutz founded a smithy to focus on the design and construction of sheetmetal-processing systems. Schnutz built its first leveling machines in 1882. |

Once cut, metal plates must be stacked to ensure smooth downstream processing. However, improperly deposited plates can damage the surfaces. “Our workpieces must satisfy strict decorative standards, so an impeccable surface is essential,” explains Rünker. “This means that they must not be scratched during stacking, and the edges must be absolutely flush.”

Such requirements prompted B+S to equip the system with a swing-arm machine to stack the sheets to 750 mm high, including the pallet, without damaging their surfaces. Special swing arms with powered transport rollers move the sheets. And, three-phase servomotors with a controlled force-velocity curve, used for the swivel and deposit movements, ensure precise swing movements. “In earlier iterations, these movements were powered pneumatically, but air is an extremely expensive medium,” says Baral. “That’s why we now use energy-efficient servomotors.”

Quick Delivery, Quick Commissioning

With each of the system’s manufacturing stages completed on schedule, B+S delivered a turnkey cut-to-length system with protective fencing to Martinrea Honsel last November.

“Although we rescheduled the delivery date,” says Rünker, “Burghardt + Schmidt still helped us by ensuring punctual delivery, and in doing so enabled quick replacement of the systems in our rolling mill.” MF

Information for this article was provided by Martinrea Honsel Germany GmbH, Meschede, Germany, www.martinrea-honsel.com; Burghardt+Schmidt GmbH, Remchingen, Germany, www.b-s-germany.de; Schnutz GmbH, Siegen, Germany, www.schnutz.com; and Abopr Pressedienst B.V., Munich, Germany, www.abopr.de

Technologies: Pressroom Automation