ABB Debuts Speedy Press-Tending Robot

October 21, 2020Comments

ABB Robotics has expanded its IRB 760 lineup of industrial robots with the launch of the IRB 760PT, aimed at press-automation applications in the automotive industry and reportedly providing 25-percent faster cycle times compared to other robot-based press-automation solutions. The revised design of the IRB 760PT reduces the interference in the robot’s fourth axis, promising to eliminate the risk of potential interference between the robot and the press. Load capacity, 450 kg; reach, 3.18 m.

ABB Robotics has expanded its IRB 760 lineup of industrial robots with the launch of the IRB 760PT, aimed at press-automation applications in the automotive industry and reportedly providing 25-percent faster cycle times compared to other robot-based press-automation solutions. The revised design of the IRB 760PT reduces the interference in the robot’s fourth axis, promising to eliminate the risk of potential interference between the robot and the press. Load capacity, 450 kg; reach, 3.18 m.

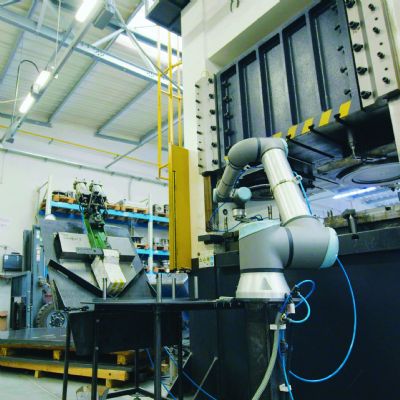

With the ability to automatically change tooling, the IRB 760PT can quickly be adapted and reprogrammed to handle new products without the need for re-engineering. For additional capability, add a linear 7th axis (ABB dubs this setup IRB 760FX) to optimally handle large panels or applications requiring part reorientation, tilting and part separation. Or, combine two IRB 760PT robots to work in tandem across 10 axes to create the IRB 760 Twin Robot Xbar (shown), ideal for loading and unloading presses with long inter-press distance without the need for press modification. Maximum output rate: 16 part/min.

“We’ve reinforced our press-automation portfolio with our fastest-ever press-tending robot,” says said Antti Matinlauri, head of product management for ABB Robotics. “Our new IRB 760PT offers optimized speed and die interferences in press-tending applications, and is a flexible and reliable solution that can quickly be implemented and easily be repurposed to handle changing future requirements.”

See also: ABB Press Automation Solutions

Technologies: Pressroom Automation