New Tooling System for Optimized Material Handling

December 1, 2019Comments

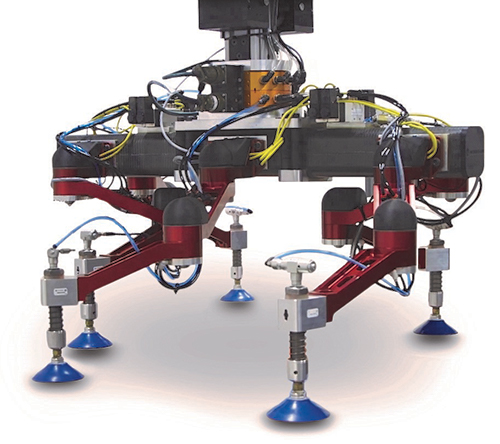

Norgren Automation Solutions, part of IMI Precision Engineering, Saline, MI, has launched a complete tooling system designed to optimize material handling applications, including in and around press cells. The innovative system, called Transforming Tooling, combines a series of arms driven by electric motion, and offers a number of significant benefits over conventional tooling solutions, including:

Norgren Automation Solutions, part of IMI Precision Engineering, Saline, MI, has launched a complete tooling system designed to optimize material handling applications, including in and around press cells. The innovative system, called Transforming Tooling, combines a series of arms driven by electric motion, and offers a number of significant benefits over conventional tooling solutions, including:

- Reduced recurring tooling costs

- Elimination of manual tool change

- Instant tool changeover between applications

- Reduced floor space requirements due to elimination of manual tooling storage

- Optimized safety on the shop floor

When the arms are actuated to the desired location, pneumatic clutches lock them in place, providing a robust and rigid setup similar to conventional end-of-arm robotic tooling solutions. When the application requires a change in handling material, the arms automatically transform the end-effector system to suit the needs for the new application, and lock in place.

The system comes with a full range of IMI Norgren consumables including vacuum cups and grippers that can be swapped on the fly.

See also: Norgren Automation Solutions

Technologies: Coil and Sheet Handling, Pressroom Automation

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted.Lift and Tilt Table Lowers to Floor Level for Hand Pallet-Tr...

Thursday, April 4, 2024

Pressroom Automation

Pressroom AutomationCustomized AMRs

Friday, March 8, 2024

Pressroom Automation

Pressroom AutomationOmron AMRs With ROEQ Lifter and Roller Modules

Friday, March 1, 2024