Partner Content

New Extended Reality (XR) Tool to Disrupt the Metal Forming Industry

June 14, 2021 Comments

SIMPAC America, North American subsidiary of South Korea’s leading press manufacturer, SIMPAC Inc., and Elm Park Labs, a Michigan-based, women-owned computer software company, have partnered together to create an exclusive extended reality (XR) tool that will change business practices and operations within the metal forming industry for the foreseeable future.

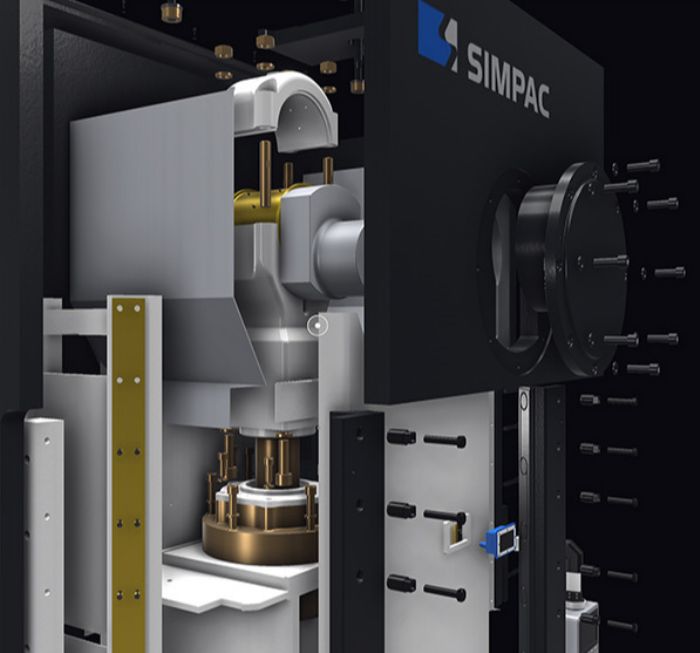

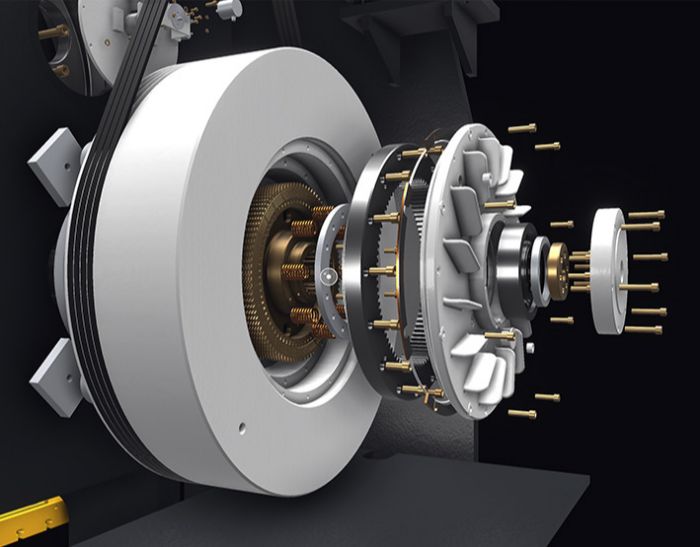

The collaboration is set to complete three project phases—for which each phase will disrupt crucial business practices within the metal forming industry: sales and marketing, buy-offs and installations, and service and operational support. The kick-off project will be an augmented reality (AR) sales and marketing software tool that will showcase SIMPAC’s CX-200 press, a press from the manufacturer’s new CX Series. The CX Series and its IIOT technology was designed specifically to accelerate small part production of stamped parts for the appliance, automotive, and other general industries.

The collaboration is set to complete three project phases—for which each phase will disrupt crucial business practices within the metal forming industry: sales and marketing, buy-offs and installations, and service and operational support. The kick-off project will be an augmented reality (AR) sales and marketing software tool that will showcase SIMPAC’s CX-200 press, a press from the manufacturer’s new CX Series. The CX Series and its IIOT technology was designed specifically to accelerate small part production of stamped parts for the appliance, automotive, and other general industries.

“We are very proud to have made such a strategic partnership with Elm Park Labs,” says YH Kim, President of North American Operations at SIMPAC America. “Together, we are expanding upon SIMPAC’s IIOT portfolio while supporting our customers as they dive deeper into Industry and Digitalization 4.0.”

Elm Park Labs will handle the design, development, testing, and deployment of the AR application that will allow SIMPAC to not only promote the new press series in a highly innovative way but also enable the press manufacturer to highlight key components of the press, its functionality, and its specific parts and capabilities. The technology will provide a three-dimensional view for which clients can use remotely and walk around with the tool during use. The solution makes it possible to view the internal components of the press and check or adjust the sizing of the press—enabling the customer to verify floorspace requirements.

“The XR ecosystem we are creating for SIMPAC is paramount to bringing a simulated and enhanced environment to the metal forming industry,” explains Kimberley Hanke, Founder & CEO of Elm Park Labs. “The robust augmented reality solution for the CX-200 press is only the beginning for this long-term partnership. The goal is to apply all sectors of extended reality in order to tackle key industry problems that will, in turn, increase turnaround times, knowledge transfer, and ultimately save costs while creating an immersive experience.”

The first phase of SIMPAC and Elm Park Lab’s XR tool will be unveiled throughout multiple events and conferences as a part of a thought leadership case study for the metal forming industry to utilize for its own benefit. The first in-depth analysis of this tool will be made available to the public through an

The first phase of SIMPAC and Elm Park Lab’s XR tool will be unveiled throughout multiple events and conferences as a part of a thought leadership case study for the metal forming industry to utilize for its own benefit. The first in-depth analysis of this tool will be made available to the public through an

Webinar

Webinar