New Software for AM Simulation

November 9, 2018Comments

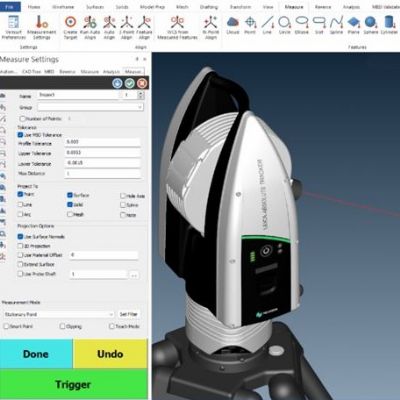

Simufact, an MSC Software Co., has introduced Simufact Additive 4–the next generation of its solution for the simulation of metal additive manufacturing (AM) processes. A scalable, practitioner-oriented product, it predicts distortion, stress and temperature effects. The software helps in optimizing build preparation and simulation, as well as subsequent steps in the AM process chain, including heat treatment, base-plate cutting, support removal and hot isostatic pressing.

“The software comes with a workflow-oriented user interface," Dr. Patrick Mehmert, Product Manager Additive Manufacturing, says. “We will further strengthen our ease-of-use approach with new functionality available in Simufact Additive 4, which efficiently guides users through the simulation process workflow and supports them with new automation and assistant functionalities.”

The software helps to identify the best build orientation, predict and completely compensate final-part distortion automatically below a given threshold, optimize support structures automatically, identify overheated or underheated zones, and predict manufacturing issues such as cracks, shrink lines and recoater contact.

With the software, users now can consider the effects of preheated base plates or build spaces, and achieve more accurate simulation results for fully nested base plates and build spaces.

See also: Simufact Engineering Gmbh

Technologies: