Proto Labs took over the Raleigh location from FineLine Prototyping in 2014, and quickly ramped up the facility’s metal-printing business by adding Concept Laser metal-printing machines to its stable. With a core competency in producing parts with small feature resolution, Proto Labs, says Bentley, began its metal-AM journey by bringing in Concept Laser MLab machines—100-W laser powder-bed models with a build envelope of 90 by 90 by 80 mm.

“We now have 17 metal machines,” Bentley shares, “eight MLabs and another nine 400-W Concept Laser M2 machines (250 by 250 by 280-mm build envelope), which produce slightly larger parts. While a large portion of our business still falls under prototyping work to validate part designs, we’re seeing a lot more customers accepting 3D metal printing for part production, with aerospace companies leading the charge. We tell customers that 3D metal printing is not a replacement technology for machining. Rather, if they can rethink their part designs and model features to improve function or reduce weight, metal AM provides new rules for manufacturability that expand its use into production work.”

Automating to Keep Pace

This is one busy AM shop, with hundreds of new part orders coming in daily. Automating its production processes has been a priority, and that starts with e-Stage.

|

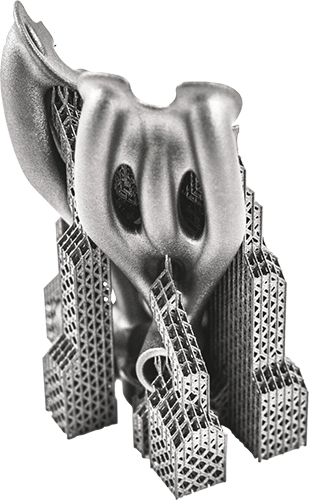

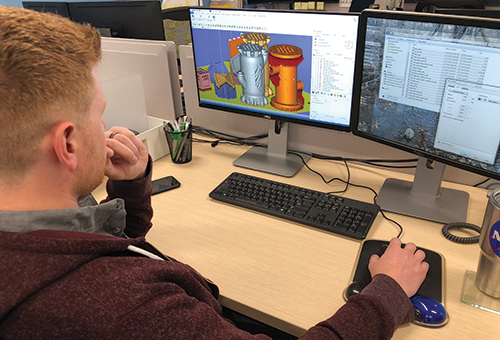

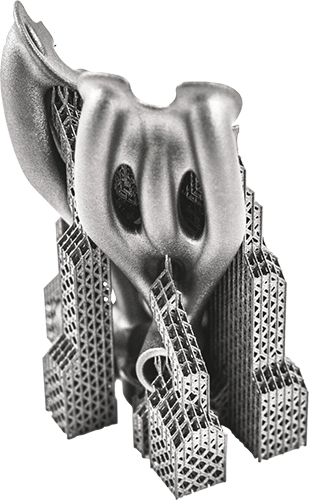

| New software becomes more impactful as part designs become more complex, requiring more supports. |

“We strive to print correctly on the first attempt,” says Bentley, “and for the most part we succeed. We have very low rebuild rates, and much of that success comes from the ability of e-Stage to remove human error from the preparation process.

“The software analyzes the part in question,” he continues, “and identifies for us the areas that need support, then automatically generates the supports. We’ve found it to be very stable and reliable…our team trusts the results, especially when it comes to holding the parts in place on the build plate during processing. Then, if there’s extra concern regarding warpage that requires extra support consideration, our team performs that design function manually.”

So, where does the return on investment come from? Answering that question, Bentley echoes what Materialise and Airbus APWorks say.

“From our experience,” he says, “powder recovery represents a huge savings for us when using e-Stage for Metal to design our supports. The scaffold-like supports developed by e-Stage contain a great deal of perforations that allow for easy powder escape and prevent entrapment between the part, the build plate and the supports. Should powder become trapped, cutting the part off of the build plate exposes the trapped powder and renders it unusable. With e-Stage we avoid that situation and minimize waste.

“e-Stage also makes it simpler for us to train new associates on support design,” Bentley continues. “It’s very intuitive and user-friendly, removing any guesswork. Once we verify the part orientation for the build, the software automatically generates all of the supports needed throughout the part. It’s all done at once based on the overhang orientations. In the end we experience very few build errors related to supports.”

Significant Time Savings

In its promotional material, Materialise says that users of e-Stage can expect as much as a 90 percent decrease in the time required to design supports compared to manual; as much as a 50 percent reduction in the time needed for support removal; and a 20 percent reduction in part-finishing time.

“Support-removal and finishing time drops because the supports, while strong, are easily crushable and allow our associates to use simple tools to remove them,” Bentley adds. “Typically they only need pliers or snips to remove the supports, and thus leave behind minimal burrs, minimizing finishing requirements.

“This type of software,” he summarizes, “becomes more important and impactful as part designs become more complex, where more supports are needed. As evidenced by the work we’re seeing, e-Stage means that we never take in a part that might stump our designers on how best to design the supports. Since e-Stage performs that task for us, the designers can focus their time and energy, and expertise, in other areas. In the end, support design now typically takes minutes instead of hours.” 3DMP

See also: Materialise USA LLC

Technologies:

Brad Kuvin

Brad Kuvin

Event

Event