An Overall QDC Strategy

It’s the new Minster press that Gray’s team added to the plant, for capacity reasons early in 2012, which most recently received an efficiency upgrade. “We’re very close to achieving our OEE goal,” he says, “a significant upgrade from where we were just a couple of years ago.” He notes that of the pressroom’s 19.2 million stamped parts/month, some 4 million comes from the Minster and 12 million from the Bruderer. That’s a 25-percent improvement due, in large part, to an emphasis on achieving quicker die changes.

“To improve die-changeover times, we have worked as a team to implement Kaizen and other lean strategies to ensure we’re prepared to run the next job scheduled for each press,” says Gray. “That means a lot of things, including staging coils and dies, and 5S strategies such as replacing cluttered tool boxes with organized boards of carefully selected point-of-use tools. The press operator’s tool set is now limited to only what’s needed to change dies.”

You Want to Install the New Press Where?

Progressive-die presses undergo an average of 90 changeovers/month, and until recently changeover time hovered around 40 min. That’s been whittled down to an average of 30 min., and as little as 24 min.

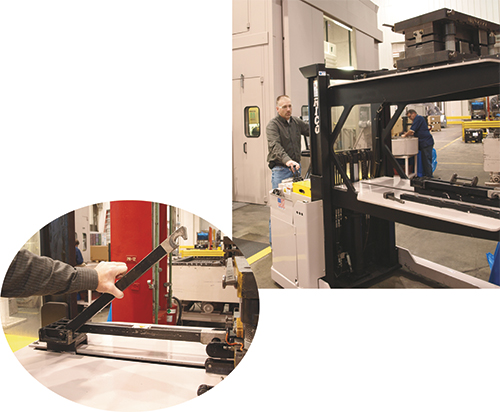

“QDC did not come easily with the Minster press,” shares Gray. “While another facility might have added on to make room for this new press, we did not have that luxury. So we squeezed it into an area inaccessible by a tow motor.”

Rico literature notes that its die handlers are designed to operate in less area than conventional forklift trucks, due to their tight turning radius. This allows less space between presses and minimizes wasted aisle space.

An Added Bonus

LuK not only employs the Rico die cart to perform die changes on the Minster press, but also uses the cart to changeover the Bruderer press, in place of a tow motor.

“On the Bruderer, the cart has shaved at least 2 min. from our changeover times,” Gray says. “And, considering the delicate, critical nature of some of our high-speed dies and the relative cost of those dies compared to the dies used to stamp clutch components, we’re much more comfortable handling those dies with the die cart rather than the tow motor.”

Another process improvement put in place to protect its valuable dies: LuK now color-codes its dies to identify dies that cannot run empty during coil-feed up, following a changeover. “We used to place a tag on the dies that were susceptible to damage when cycled without stock,” explains Gray. “To completely eliminate empty hits and die damage, we now paint those dies a different color. It’s worked perfectly since we implemented the idea about a year ago.”

A Sense of Urgency on the Floor

The use of the die cart, and the need to carefully schedule its use so that it’s available when the Minster and Bruderer need it, is indicative of the overall sense of urgency evident in the LuK pressroom. Press operators are responsible for attaining established OEE goals.

As such, LuK’s press operators have engineered several Kaizen events to help quicken the pace at which materials move through the shop. One example we spied: each press line includes a set of three signposts used to signal to the pressroom team the status of the line. Green signs indicate the presence in the press cell of the blanking and forming dies and coils needed for the next job scheduled to run; a red sign means something’s missing in order for the next job to run. As we toured the pressroom, all we saw were green signs—excellence in action.

“This is just one of many action items initiated from ideas provided by our crew,” says Gray, “that add up to squeezing as much productivity and throughput we possibly can from our existing press capacity.

“On the progressive-die side of the pressroom,” Gray continues, “we’ve now been able to back off from seven-day production to a normal five-day schedule. And when the new Schuler transfer press comes online early in 2014, we expect the same to occur in the transfer-press area.” MFView Glossary of Metalforming Terms

See also: Nidec Press & Automation, Bruderer Machinery, Inc., Schuler North America

Technologies: Stamping Presses

Video

Video