At each of the two facilities manufacturing the security labels, Motoman six-axis material-handling robots load styrene-coated sheetmetal blanks, one robot serving each press. Underneath each blanking die feeds, left to right, a continuous roll of adhesive-backed liner, so that as the blanked labels fall from the sheet they adhere to the liner, which then rewinds at the opposite end of the press. The liner steps and repeats in registration with the press stroke, with a cycle time of 4.7 sec.“When we approached Neff Press to help us upgrade production, we asked for a 5-sec. cycle time,” recalls Simone, “quite a significant improvement

|

| Sensormatic UltraMax anti-theft labels comprise a metal-alloy tab coated with multiple layers of styrene laminate. One stroke in a hydraulic press blanks 144 of the labels out of a large s |

from the 11-sec. cycle time we had been achieving. Eliminating the pad bounce, in addition to firming up the press structure, got us where we wanted to be, and beyond.”

Better Control = Less (Zero) Scrap

Eliminating pad bounce from the 16-ton stripping force was achieved thanks to a dramatic upgrade in hydraulic circuitry, says Simone. “The original presses used fixed-displacement pumps and solenoid-operated valves,” he says, which offered little process control. “The newer presses use variable-displacement pumps and proportional valves, which give us better control of all of the fluid in the presses.

“Neff designed a decompression hydraulic circuit and timing sequence specifically to handle the blanking load,” adds Simone, “and the end result is that where we used to have to scrap an average of four to six labels per set of 144, we now achieve better than 99.9 percent quality from the press lines.”

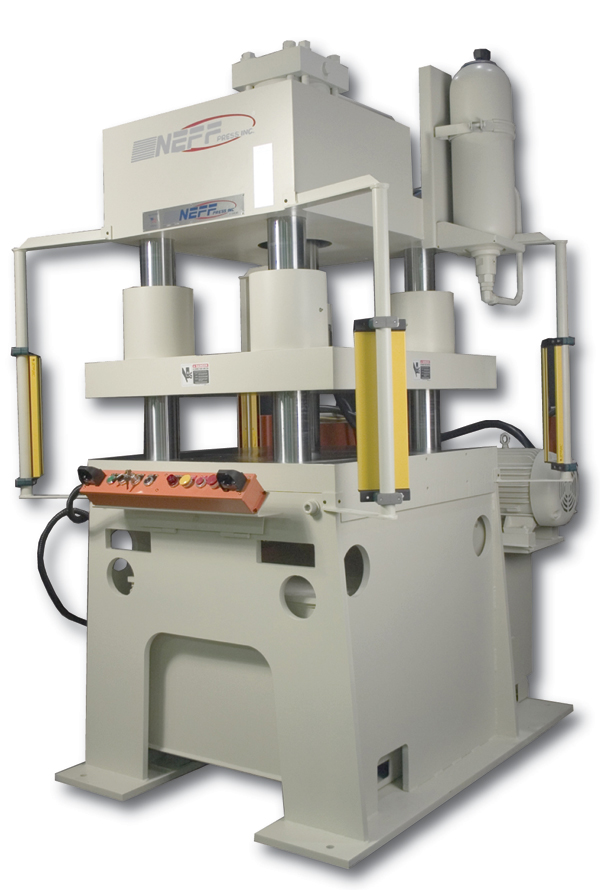

The Neff 4-post presses are H40-30M models with beds 33 in. left to right, 33 in. front to back and with 30 in. of daylight. A cutout in the bottom bolster of each press allows the positioning of a vision system used to inspect the security labels in-process. The power unit—motor and pump assembly—mount externally and upside down to provide full access to all four sides of each press, allowing Sensormatic to easily integrate the coil-feed system that delivers the adhesive-backed liner, as well as the robot, vision system and scrap-removal system.

Each press runs with a 12-in. stroke, 2 in. of work in 2.9 sec. And a 30-hp power unit generates ram speeds as high as 1200 in./min. MF

View Glossary of Metalforming Terms

See also: Neff Press, Inc.

Technologies: Stamping Presses

Video

Video