Five Tips for Better Aluminum GMAW

August 25, 2019Comments

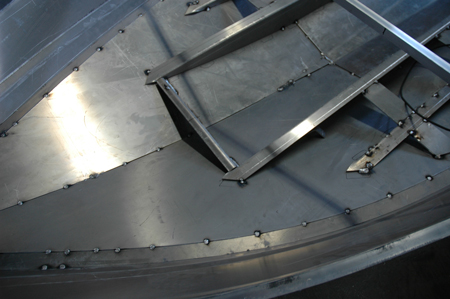

Lightweight, easy to form and resistant to rust, aluminum sheet metal offers manufacturers the option of skipping the painting step when producing parts. These benefits make the material popular in a range of applications, from toolboxes and jon boats to signs and awnings.

Lightweight, easy to form and resistant to rust, aluminum sheet metal offers manufacturers the option of skipping the painting step when producing parts. These benefits make the material popular in a range of applications, from toolboxes and jon boats to signs and awnings.

|

| Pulsed GMAW significantly lowers the necessary heat input, enabling easier welding of thin materials such as aluminum sheet while minimizing burnthrough. |

1Use pulsed GMAW welding. The right welding process helps improve results. For example, pulsed GMAW lowers the heat input and makes it easier to weld thin materials and minimize burnthrough. This welding process alternates between a high peak current and a lower background current, which lowers overall amperage. The pulse of peak current propels the molten droplet across the arc and provides the energy to produce good fusion associated with spray transfer, while the low background current allows the weld puddle to cool.

Pulsed GMAW also allows operators to run larger-diameter wire at lower currents than needed to run a non-pulsed process, such as constant-voltage (CV) GMAW. In addition, pulsed GMAW provides the ability to better control the bead profile. A wider arc cone helps tie-in both sides of a joint or an outside corner, where a narrow arc cone helps focus the arc and provides good fusion at the root of a joint. Adjusting the arc length (voltage) and wire-feed speed for optimum performance helps eliminate excess heat input, overwelding (making welds that are larger than needed or using too much filler material) and post-weld grinding.

2 Choose the best-possible filler-metal alloy. Selecting the best filler metal for welding aluminum sheet presents many factors to consider, such as the base-metal alloy, service temperature, environment, formability and more. |

| Proper, tight part fitup is especially important when welding thin material such as sheet metal, as gaps between the pieces to be welded can cause warpage. |

Common base metals compatible with 4043 and 4047 filler metals include types 3003, 3004, 6061, 6063, 5005, 5050 and 5052. When using pulsed-GMAW on material from 1⁄8 in. thick to 16-gauge, a 3⁄64-in.-thick filler metal can be used, provided the weld area has a tight fitup. For even thinner materials, try a 0.035-in. filler metal. For CV GMAW on sheet metal, we recommend wire diameters of 0.035 to 0.030 in.

Note that readily available 100-percent-argon shielding gas is common for GMAW aluminum-sheet applications.