| Just Two Days Left to Respond to AM Post-Processing Survey |

| The

fourth annual edition of the Additive Manufacturing Post-Processing

Industry Trends Survey, sponsored by PostProcess, seeks participation

from additive manufacturing (AM) technology users by November 4. The

survey explores needs and solutions by market, providing an in-depth,

segmented look at AM post-processing across a myriad of applications. |

|

|

|

|

|

|

|

| Sponsored |

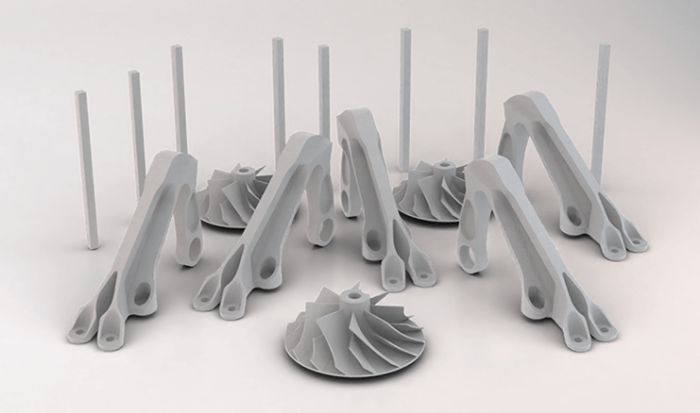

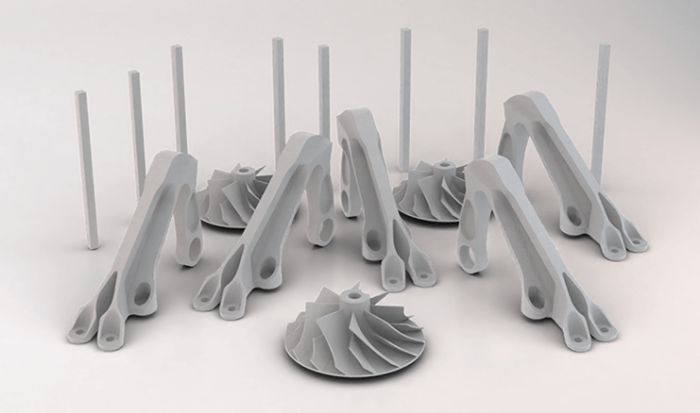

| Jumpstart Your Metal AM |

| With

the largest build envelope in its class and the same laser power as our

larger metal printers, the DMP Flex 200 offers outstanding accuracy,

repeatability, and surface finish. Perfect for R&D, prototyping,

academia, and small part production, this compact workhorse empowers you

to achieve your metal AM goals. |

|

|

|

|

|

|

|

|

|

|

|

| 6K Additive Tour Details Expansion to Double Powder-Manufacturing Capacity |

| 6K Additive

unveiled plans to double its powder-manufacturing capacity in

Burgettstown, PA, including a facility-size increase of 35,000 sq. ft.

and the adding of as many as 35 employees. A division of 6K, 6K Additive

offers what it describes as sustainable production of engineered

materials for AM and lithium-ion batteries via its UniMelt plasma

technology. |

|

|

|

|

|

|

|

|

|

| Sponsored |

| Vacuum Heat Treating 3D Metal Printed Components |

| Since

3D printing builds to near net or finished dimensions, vacuum heat

treating is an absolute necessity. Vacuum levels that approach 1 X 10-6

Torr produce clean and oxide-free surface conditions that are

metallurgically stable. Critical temperature control is also a must to

avoid cracking and producing a strong and ductile part. |

|

|

|

|

|

|

|

|

|

|

|

| Hexagon, Raytheon Technologies Develop AM-Build Simulation Software |

| Hexagon’s Manufacturing Intelligence division and Raytheon Technologies’ Pratt and Whitney business have partnered to develop a simulation tool for evaluating and optimizing metal-AM processes through the prediction of thermal history and defects at the laser-path and powder-layer scale. The new software will predict defects before the expensive and time-consuming printing process begins, with this analysis helping designers and engineers evaluate the print outcome and test combinations of materials, geometries and print processes. |

|

|

|

|

|

|

|

|

|

| Sponsored |

| Fast Track Your Metal 3D Printing Strategy |

| Are

you considering the impact metal 3D printing could have on your

business? Have applications you think could be a good fit? Need help

figuring out which technology is right for you? Download this eGuide to

gain powerful insights that will save you time and money. |

|

|

|

|

|

|

|

|

|

| Spee3d Debuts Containerized Metal 3D Printer |

|

|

|

|

Spee3d has rolled out XSpee3d, a fully transportable metal-AM machine housed as a standard shipping container with the printer and all auxiliary equipment in one box. Quickly deployable, it requires only a connection to electrical power. Developed with military deployable field operations in mind, the XSpee3d uses the company’s Supersonic Deposition process that reportedly cold-spray deposits—via kinetic energy rather than high-power lasers and gases.

“One of the most significant issues the military faces today is the ability to resolve critical spare-part requirements in the field, a challenge that worsens in the face of global supply-chain issues,” says Byron Kennedy, Spee3d CEO. “With the introduction of the XSpee3d, we’re solving this issue with the ability to make reliable and affordable metal parts from anywhere, including in harsh, remote military field conditions.” |

|

|

|

|

|

|

|

|

|

|

| AddUp Machine Slated for New WBA Tooling Academy Platform in Germany |

| The WBA Tooling Academy in Germany is equipping its new AM platform with an AddUp laser powder-bed fusion (LPBF) machine for use by manufacturers on tooling projects. With this machine, tool makers who submit application cases to WBA will be able to go beyond simple proof of concept—instead having the ability to study all aspects of their projects, from the design applied to LPBF technology to the profitability analysis and the study of series production, explain AddUp officials. |

|

|

|

|

|

|

|

|

|

| FDA Clearance for ulrich Ti Cervical Interbody Device |

ulrich

medical USA, Inc. announced that it has received FDA 510(k) clearance

for its Flux-C porous titanium cervical interbody device, printed via

direct metal laser sintering.

“Surgeons have many options for cervical interbodies,” explains Dr. Patrick Maloney, the newest member of ulrich Medical USA’s Surgeon Advisory Board and its recently established director of deformity. “The Flux-C porous titanium device offers one of the best in class with superior endplate contact and spaces for generous interdevice bone grafting. |

|

|

|

|

|

|

| Dyndrite-SLM Solutions Collaboration to Support CAD-to-Print Capabilities |

Dyndrite,

provider of a GPU-accelerated computation engine used to create digital

manufacturing hardware and software, announced a collaboration with SLM

Solutions for support of the SLM file format within its application

development kit (ADK). Dyndrite delivers an ADK which provides

GPU-powered 3D CAD-to-print software development. Through the

collaboration, SLM AM-machine customers will be able to design

parameters based on unique aspects, or their unique needs, and enable

development of new IP, as well as the ability to protect any know-how

and gain competitive advantage, according to Dyndrite officials.

“The future of AM is open,” says Harshil Goel, Dyndrite CEO. “Only through democratization will the industrialization of AM advance at a faster pace.” |

|

|

|

|

|

CNC Punching

CNC Punching Pressroom Automation

Pressroom Automation

Event

Event