| Technology Focus: Robotics/Automation |

| MetalForming brings you the November installment of our monthly Technology Focus newsletter, this month highlighting Robotics/Automation. |

|

|

|

|

| Last Chance! Hot Stamping Conference and Plant Tour |

| It’s your last chance to be in Novi, MI, November 29-30 as MetalForming

magazine and the Precision Metalforming Association deliver the 4th

annual Hot Stamping Experience and Tech Tour. This event provides a

unique opportunity to dive deeply into the ever-expanding world of hot

stamping, highlighted by a tour of the GNS North America hot stamping

facility in Canton Township, MI. |

|

|

|

|

|

|

|

| Sponsored |

| Switch to Better End-Of-Arm Tooling |

| Transporter® Switch Series (TPS) Magnets are ideal for use where vacuum cups and grippers are used for lifting and moving steel sheets, blanks, parts, and assemblies in automated press-to-press transfer or robotic "pick and place" applications. They are perfect for clean room environments. NO dirty air exhausted to the atmosphere. |

|

|

|

|

|

|

|

|

|

|

|

| No Choice But to Automate |

| Automation

has become the only option for stampers in a growing number of cases.

The value of the parts a company can stamp, assemble and ship by adding

automation to a line often and easily will exceed the automation

investment. Factory output increases without adding people. |

|

|

|

|

|

|

|

|

|

| Sponsored |

| Looking to Offload Structural Stampings? |

| Tooling

Tech Group offers stamping production services and has six presses

ranging in size from 500 tons to 2,750 tons. Our equipment can process a

wide range of materials including dr steel, hr steel, galvanized,

stainless, aluminum, and advanced high-strength steels (ahss). Let us

become your strategic partner for optimal metal stamping services. |

|

|

|

|

|

|

|

|

|

|

|

| Be in Nashville in January for Metal Stamping Technology Conference |

| The Metal Stamping Technology Conference, produced by PMA and MetalForming magazine,

returns to Nashville, TN, in 2023, on January 24-25. This signature

event will feature keynote presentations, breakout educational sessions,

exhibits and a networking reception for more than 200 attendees and

sponsors. Sessions cover emerging, evolving and maturing technologies

and industry trends that are impactful to metal stamping, die design and

die construction companies. |

|

|

|

|

|

|

|

|

|

| Sponsored |

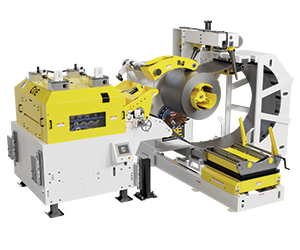

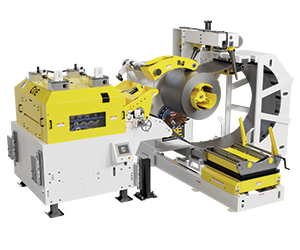

| Flatten & Feed AHSS, Even in Constrained Spaces |

| COE’s SpaceMaster™ compact coil processing systems can achieve the flatness required to process today’s dual and triple phase steels, while requiring only half the floor space. Backed by FEA and our “Science Behind the Solution” calculators, these systems effectively address coil set, as well as crossbrow in many situations. |

|

|

|

|

|

|

|

|

|

|

|

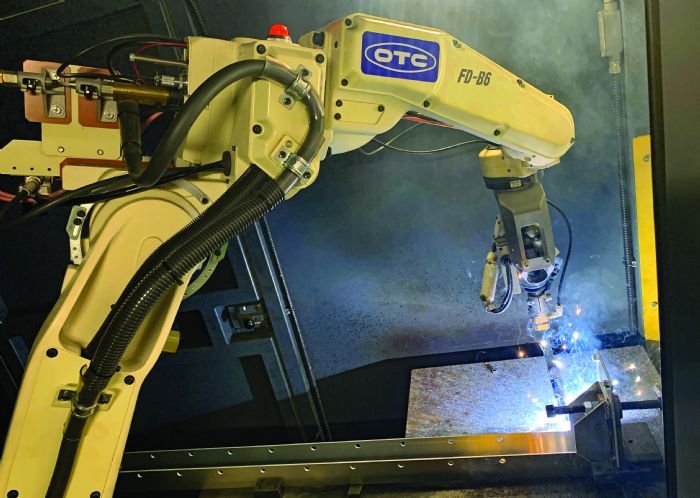

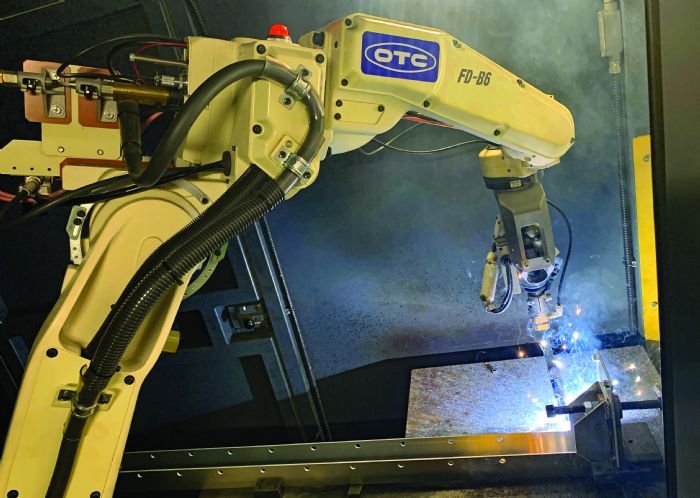

| Automation in Abundance, Arc Welding Included |

| Robotic

arc welding productivity jumps 30 percent when a new state-of-the-art

cell steps in for one nearing the end of its useful life. Upgrades in

robot performance and welding technology improve weld quality, reduce

rework and make spatter removal a distant memory. |

|

|

|

|

|

|

|

|

|

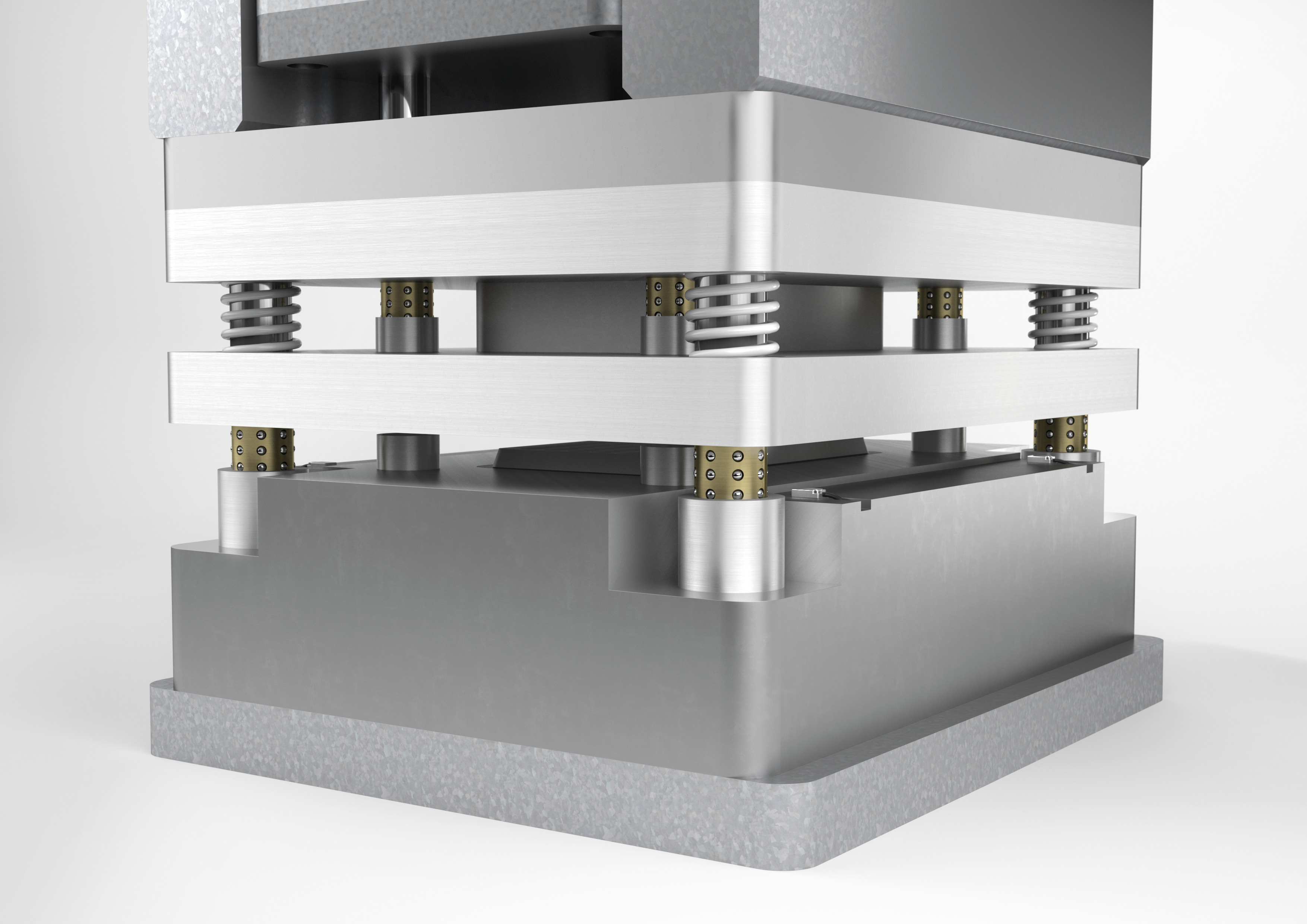

| Sponsored |

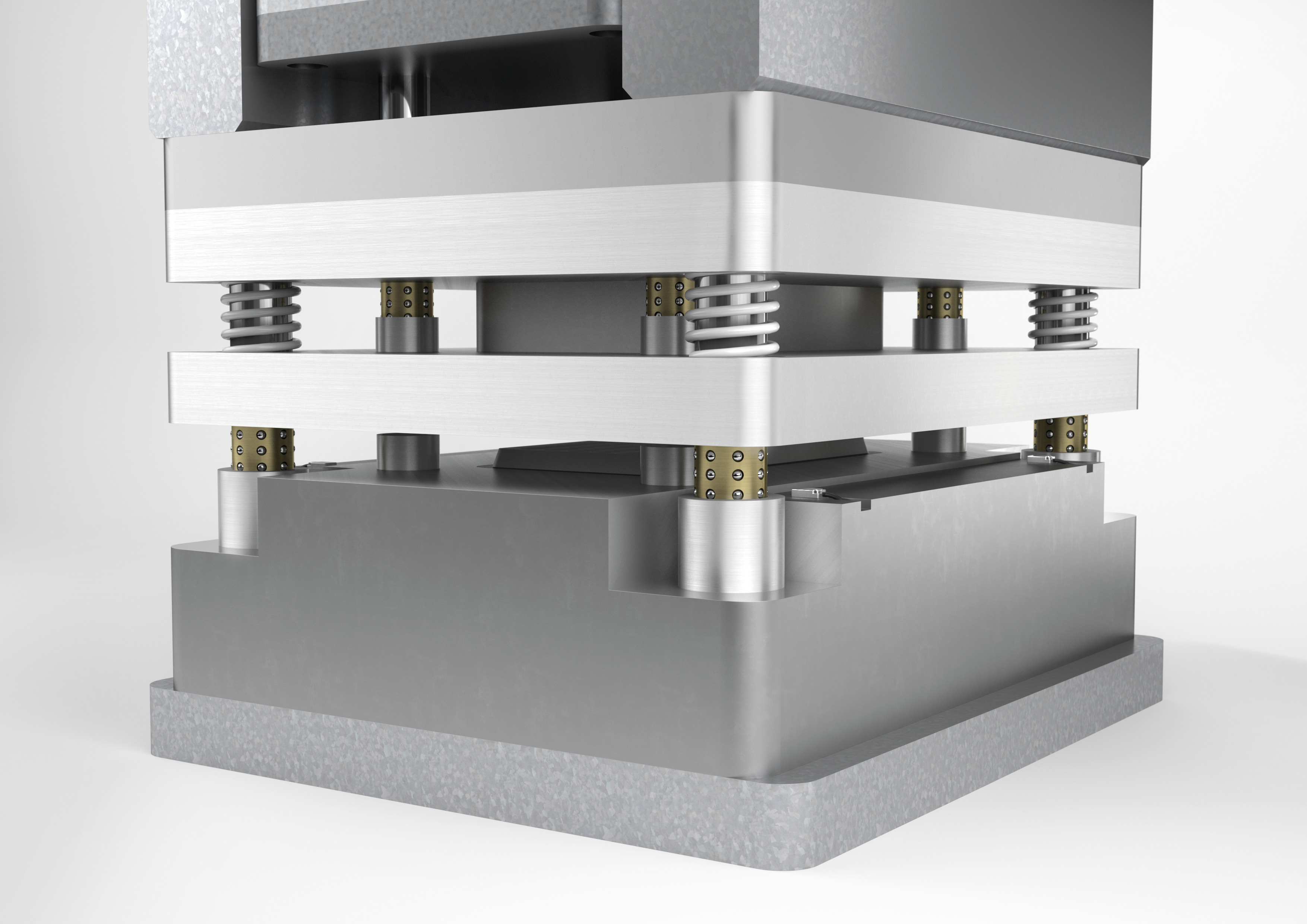

| Introducing a New CX Series |

CX

Series is optimized for small part production with a press capacity

range of 80-300 tons. These presses are ideal for punching and cutting

applications with a higher degree of automation along with SIMPAC Press

Monitoring System (SPMS) enables predictive maintenance.

Discover a New CX Series today or reach out to your local representative at support@simpac-america.com |

|

|

|

|

|

|

|

|

|

|

|

| Sponsored |

| Die Protection Solutions by Pepperl+Fuchs |

| The

repair costs from even a minor die crash can run into the tens of

thousands of dollars. Add in the associated loss of productivity, and it

is clear why preventing die crashes is a high priority. Pepperl+Fuchs

offers various industrial sensors that are ideal for protecting dies. |

|

|

|

|

|

|

|

|

|

|

|

| From the November Issue of MetalForming |

| People Drive the Automation Equation |

The

manufacturers who seem to benefit most from the increase in automation

are those who value people in their automation decisions. Even in

lights-out operations, robots and other automation rely on humans for

programming, maintenance and other functions, and humans often benefit

from inclusion of automation. In short, for successful manufacturers,

people and automation form a positive symbiotic relationship.

Metal Properties: Total Elongation

Metal certs document the tensile properties of your purchased coils.

Elongation is one measure of ductility, as denoted by the E in the YTE

abbreviation. This article discusses elongation at fracture and

elongation after fracture, with both distinct from uniform elongation. |

|

|

|

|

|

|

|

|

| Upcoming Issues |

December

- Mechanical Presses

- Women of Excellence Awards

- Preview: Metal Stamping technology Conference

- CNC Punching and tooling

- Material Handling

- Technology and Enewsletter Focus: Software

January/February 2023

- Annual Industry Outlook

- Servo Technology

- Laser Cutting

- Resistance Welding

- Technology and Enewsletter Focus: Software for Manufacturing

SPECIAL: All-Automotive Issue (February)

- Automotive/EV Stamping and Fabricating

- Stamping of AHSS and Aluminum Alloys

- Preview: Great Designs in Steel

- Technology and Enewsletter Focus: Stamping Presses

|

|

|

|

|

|

|

|

|

| MetalForming magazine is the official publication of Precision Metalforming Association. |

| PMA Services Inc. |

6363 Oak Tree Blvd. | Independence, OH 44131-2500 | USA

216-901-8800 |

|

|

|

|

|

Management

Management Stamping Presses

Stamping Presses

Event

Event