Page 24 - MetalForming March 2010

P. 24

Tooling Technology

Stuart Keeler (Keeler Technologies LLC) is best known worldwide for his discovery of forming limit diagrams, development of circle grid analysis and implementation of other press shop analysis tools. Stuart’s sheetmetal forming experience includes 24 years at National Steel Corporation and

12 years at The Budd Company Technical Center, enabling him to bring a very diverse background to this column and the many seminars he teaches for PMA. His most recent project is technical editor of the AHSS Application Guidelines—Version 4.1, which now is available for downloading free from www.worldautosteel.org. Keeler Technologies LLC

P.O. Box 283

Grosse Ile, MI 48138

Fax: 734/671-2271

E-mail: keeltech@comcast.net

Assume you have a troublesome pro- duction stamping that experiences periodic fracture at the same loca- tion. While examining several of the fractured stampings, a tool and die maker explains that he experienced a similar failure in a similar part several years ago. His solution was grinding a depression in the blankholder to allow extra material to flow into the critical area. Should his suggestion be applied to your problem stamping? Instead, red flags should start waving and alarm bells should sound warnings.

Similar is not identical. Each stamp- ing has 50 or more input variables. For ease of analysis, these variables are divide into six categories: part design, tool design, press, workpiece material, lubricant and operator. Many of the variables are interactive, which makes the problem of understanding the influ-

ence of each variable on the final con- dition of the stamping even more com- plex. Consider that one or more input variables already are causing your stamping to fracture or not fracture during a single production run.

What are the odds that the corrective action used years ago will correct the current problem? The most probable result of the blankholder grinding will be a complete disaster that will require a new tryout process to bring the form- ing system back into a successful oper- ating window. A stamping with peri- odic successes and failures in the same run means that only a limited number of input variables are susceptible to change and the changes probably are very subtle.

Good troubleshooting procedures require three pieces of data. The first is a numerical definition of the problem

THE SCIENCE OF FORMING

Have You Upgraded Your Troubleshooting Process?

STUART KEELER

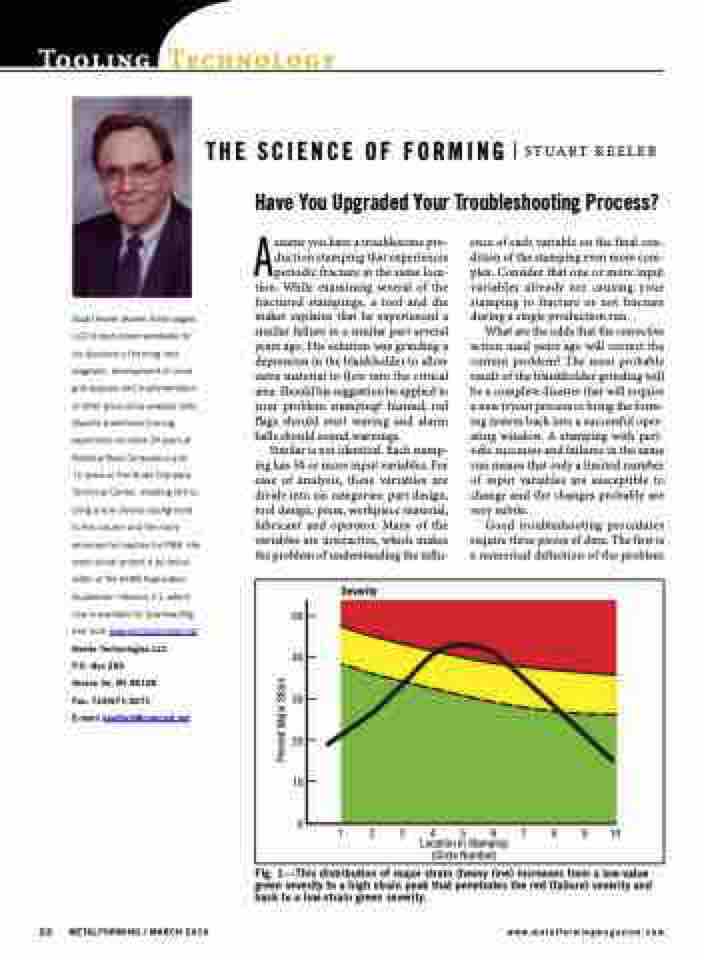

Severity

50

40

30

20

10

0

1 2 3 4 5 6 7 8 9 10 Location in Stamping

(Circle Number)

22 METALFORMING / MARCH 2010

www.metalformingmagazine.com

Fig. 1—This distribution of major strain (heavy line) increases from a low-value green severity to a high strain peak that penetrates the red (failure) severity and back to a low-strain green severity.

Percent Major Strain