Page 32 - MetalForming November 2010

P. 32

Tooling Technology Pressure

Sensors

One of the most important yet least obvious ways to improve die per- formance in stamping operations concerns lubrication. Proper lubrica- tion helps offset the friction and high heat that occurs each time the die impacts a piece of sheetmetal. These forces not only cause equipment to wear over time, but they also may cause immediate damage to the tool or part. For example, slugs—the pieces of mate- rial extracted from the part during stamping—can remain on a part after stamping, obstructing the operation and causing subsequent stamped parts to be labeled as rejects.

Not Too Much, Not Too Little

Stampers rely on lubricant to help ensure the production of high-quality parts, and to protect and extend the life of the press and tooling. The effec- tiveness of the lubricant relies on ensur- ing the delivery of the proper amount of lubricant consistently, hit after hit.

Lubricant—typically stored in a tank next to the press line, and piped out through a nozzle—is applied either by spraying onto the sheetmetal or by mist- ing directly onto the die; a valve controls the amount of lubricant delivered. To optimize results, stampers should con- sider monitoring and controlling the amount of lubricant applied with each press stroke—too much can lead to slug pulling, while too little will allow the detrimental effects of friction and heat to appear, such as tool galling, which interferes with the subsequent flow of

Melissa Schumann is a product manag- er at Turck, Inc., Plymouth, MN; 763/553-7300, www.turck-usa.com.

...help dies live a long and healthy life.

BY MELISSA SCHUMANN

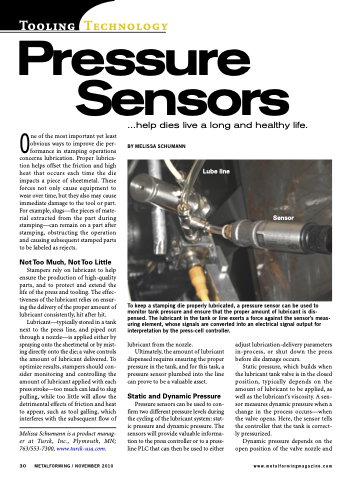

Lube line

Sensor

To keep a stamping die properly lubricated, a pressure sensor can be used to monitor tank pressure and ensure that the proper amount of lubricant is dis- pensed. The lubricant in the tank or line exerts a force against the sensor’s meas- uring element, whose signals are converted into an electrical signal output for interpretation by the press-cell controller.

lubricant from the nozzle.

Ultimately, the amount of lubricant

dispensed requires ensuring the proper pressure in the tank, and for this task, a pressure sensor plumbed into the line can prove to be a valuable asset.

Static and Dynamic Pressure

Pressure sensors can be used to con- firm two different pressure levels during the cycling of the lubricant system: stat- ic pressure and dynamic pressure. The sensors will provide valuable informa- tion to the press controller or to a press- line PLC that can then be used to either

adjust lubrication-delivery parameters in-process, or shut down the press before die damage occurs.

Static pressure, which builds when the lubricant tank valve is in the closed position, typically depends on the amount of lubricant to be applied, as well as the lubricant’s viscosity. A sen- sor measures dynamic pressure when a change in the process occurs—when the valve opens. Here, the sensor tells the controller that the tank is correct- ly pressurized.

Dynamic pressure depends on the open position of the valve nozzle and

30 METALFORMING / NOVEMBER 2010

www.metalformingmagazine.com