Page 87 - MetalForming October 2011

P. 87

Fig. 2

concern. All hole extrusions start as hole expansions (Fig. 2), where a punch is forced into a blanked hole, causing a circumferential elongation or stretching of the cut edge. Absolute values of expansion limits depend on the mate- rial, tool design, lubrication and edge quality of the punched hole. Fig. 3, illustrates the negative impact that cutting-edge damage can have on hole expansion and hole extruding.

If the amount of stretching required to form the hole extrusion exceeds the residual stretchability of the cut edge after punching, consider of one several options available for restoring edge stretchability:

• Improve the quality of the original cutting operation; • An additional cut of higher quality; or

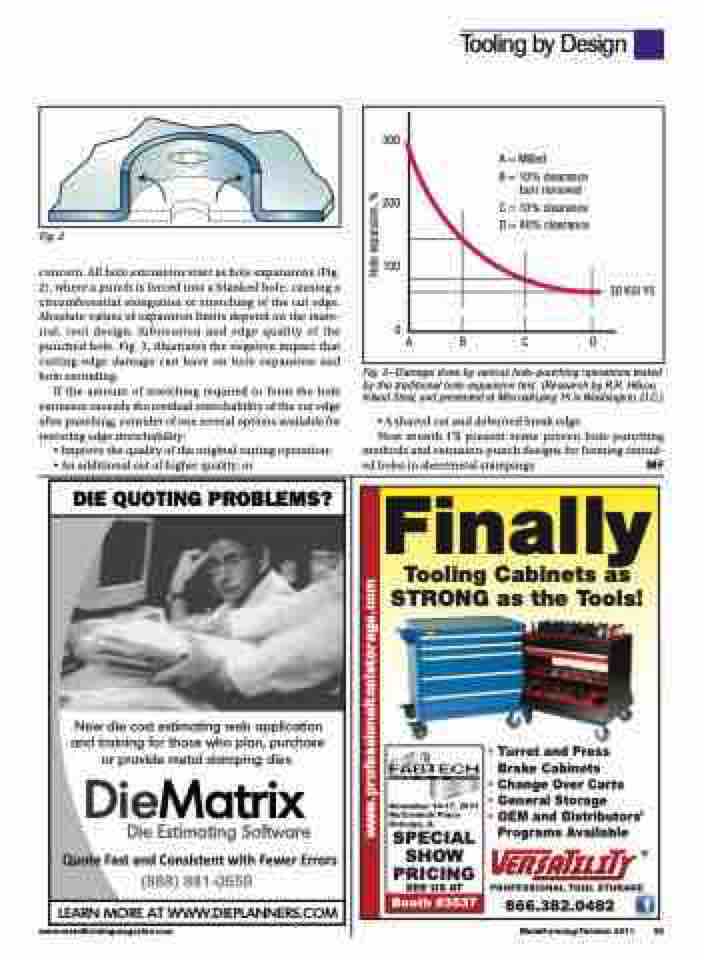

Fig. 3—Damage done by various hole-punching operations tested by the traditional hole-expansion test. (Research by R.R. Hilson, Inland Steel, and presented at Microalloying 75 in Washington, D.C.)

• A shaved cut and deburred break edge.

Next month I’ll present some proven hole-punching methods and extrusion-punch designs for forming extrud- ed holes in sheetmetal stampings. MF

Tooling by Design

300

200

100

A = Milled

B = 10% clearance burr removed

C = 10% clearance D = 40% clearance

30 KSI YS

0

AB C D

DIE QUOTING PROBLEMS?

Finally Tooling Cabinets as STRONG as the Tools!

� Turret and Press Brake Cabinets

� Change Over Carts

� General Storage

� OEM and Distributors’

Programs Available

PROFESSIONAL TOOL STORAGE 866.382.0482

mber 14-17, 2011 McCormick Place

Chicago, IL

PECIAL

SHOW

PRICING EE US AT

Nove

S S

Booth #3537

New die cost estimating web application and training for those who plan, purchase or provide metal stamping dies.

DieMatrix Die Estimating Software

Quote Fast and Consistent with Fewer Errors

(888) 881-0659

LEARN MORE AT WWW.DIEPLANNERS.COM

www.metalformingmagazine.com

MetalForming/October 2011 85

www.professionaltoolstorage.com

Hole expansion, %