Page 28 - MetalForming May 2010

P. 28

Tooling Technology Simulation Software

Streamlines Die Build

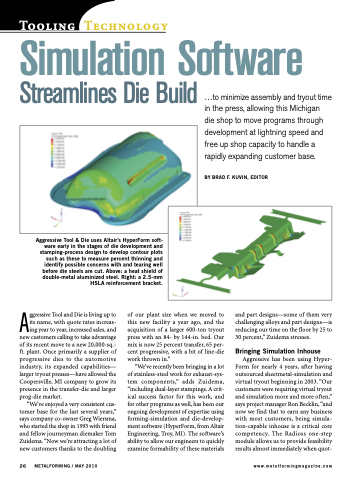

Aggressive Tool & Die uses Altair’s HyperForm soft- ware early in the stages of die development and stamping-process design to develop contour plots such as these to measure percent thinning and identify possible concerns with and tearing well before die steels are cut. Above: a heat shield of double-metal aluminized steel. Right: a 2.5-mm HSLA reinforcement bracket.

...to minimize assembly and tryout time in the press, allowing this Michigan die shop to move programs through development at lightning speed and free up shop capacity to handle a rapidly expanding customer base.

BY BRAD F. KUVIN, EDITOR

Aggressive Tool and Die is living up to its name, with quote rates increas- ing year to year, increased sales, and new customers calling to take advantage of its recent move to a new 20,000-sq.- ft. plant. Once primarily a supplier of progressive dies to the automotive industry, its expanded capabilities— larger tryout presses—have allowed the Coopersville, MI company to grow its presence in the transfer-die and larger prog-die market.

“We’ve enjoyed a very consistent cus- tomer base for the last several years,” says company co-owner Greg Wiersma, who started the shop in 1993 with friend and fellow journeyman diemaker Tom Zuidema. “Now we’re attracting a lot of new customers thanks to the doubling

of our plant size when we moved to this new facility a year ago, and the acquisition of a larger 600-ton tryout press with an 84- by 144-in. bed. Our mix is now 25 percent transfer, 65 per- cent progressive, with a bit of line-die work thrown in.”

“We’ve recently been bringing in a lot of stainless-steel work for exhaust-sys- tem components,” adds Zuidema, “including dual-layer stampings. A crit- ical success factor for this work, and for other programs as well, has been our ongoing development of expertise using forming-simulation and die-develop- ment software (HyperForm, from Altair Engineering, Troy, MI). The software’s ability to allow our engineers to quickly examine formability of these materials

and part designs—some of them very challenging alloys and part designs—is reducing our time on the floor by 25 to 30 percent,” Zuidema stresses.

Bringing Simulation Inhouse

Aggressive has been using Hyper- Form for nearly 4 years, after having outsourced sheetmetal-simulation and virtual tryout beginning in 2003. “Our customers were requiring virtual tryout and simulation more and more often,” says project manager Ron Becklin, “and now we find that to earn any business with most customers, being simula- tion-capable inhouse is a critical core competency. The Radioss one-step module allows us to provide feasibility results almost immediately when quot-

26 METALFORMING / MAY 2010

www.metalformingmagazine.com