Page 28 - MetalForming August 2010

P. 28

Tooling Technology

Meet the Next Generation

of Tool Steels

...developed to take on the demanding tasks of blanking, forming and trimming the latest- greatest HSLA and AHSS sheet steels.

BY PATRICIA MILLER

Changes within the automotive industry with respect to crash wor- thiness, while still meeting ongoing criteria for reduced fuel consumption, have catapulted the industry toward the use of high-strength low-alloy (HSLA) and advanced high-strength steels (AHSS), for critical functional components previously produced from mild steels. As automotive OEMs cele- brate these accomplishments, metal- formers are left with the difficult tasks of blanking, forming and trimming these new steels, which places escalating demands on the tooling being used.

Metalformers working with these new alloys no longer can depend on conventional tool steels, such as AISI D2, to give them the production per- formance they’re used to seeing. There- fore, tool-steel grade development and improvements in production methods are working in tandem to allow the manufacture of new higher-strength, tougher and more ductile tool steels. These new tool steels are made possible only by an improvement in steel homo- geneity and purity resulting from

Patricia Miller is senior technical man- ager, Bohler-Uddeholm Corp., Elgin, IL: 800/638-2520, www.bucorp.com.

improved remelting technology and from the third generation of powder- metal (PM) alloys.

New Grades Developed Through Remelting

Enhancements made to the elec- troslag remelting (ESR) process have enabled tool-steel providers to develop cleaner and more homogeneous alloys.

This special remelting technology ensures low micro- and macro-segre- gation and gives the tool steels the clean- liness and homogeneity required for optimum performance in service. The table below shows the composition of two of these new 8 Cr cold-work tool steels.

The excellent property profile of these 8 Cr steels also serves to bridge the

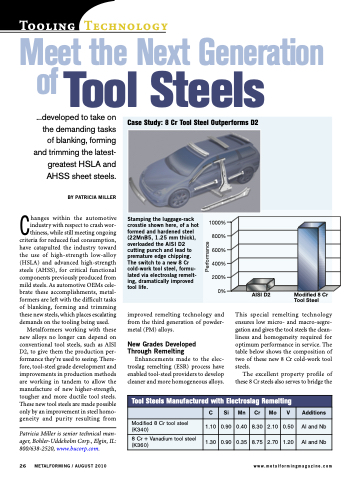

Case Study: 8 Cr Tool Steel Outperforms D2

Stamping the luggage-rack crosstie shown here, of a hot formed and hardened steel (22MnB5, 1.25 mm thick), overloaded the AISI D2 cutting punch and lead to premature edge chipping. The switch to a new 8 Cr cold-work tool steel, formu- lated via electroslag remelt- ing, dramatically improved tool life.

1000% 800% 600% 400% 200%

0%

AISI D2

Modified 8 Cr Tool Steel

Tool Steels Manufactured with Electroslag Remelting

C

Si

Mn

Cr

Mo

V

Additions

Modified 8 Cr tool steel (K340)

1.10

0.90

0.40

8.30

2.10

0.50

Al and Nb

8 Cr + Vanadium tool steel (K360)

1.30

0.90

0.35

8.75

2.70

1.20

Al and Nb

26 METALFORMING / AUGUST 2010

www.metalformingmagazine.com

Performance