Page 41 - MetalForming January 2014

P. 41

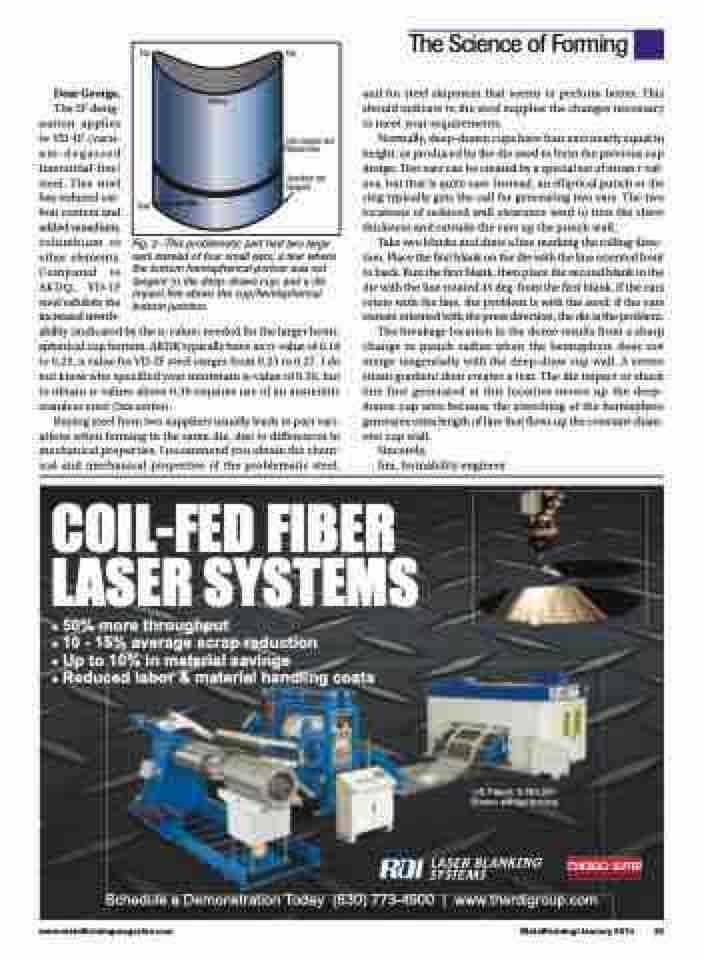

Ear

Ear

Tear

Valley

Die impact line Shock line

Junction not tangent

Dear George,

The IF desig-

nation applies

to VD-IF (vacu-

um-degassed

Interstitial-free)

steel. This steel

has reduced car-

bon content and

added vanadium,

columbium or

other elements.

Compared to

AKDQ, VD-IF

steel exhibits the

increased stretch-

ability (indicated

spherical cup bottom. AKDK typically have an n-value of 0.18 to 0.23; n value for VD-IF steel ranges from 0.23 to 0.27. I do not know who specified your minimum n-value of 0.30, but to obtain n-values above 0.30 requires use of an austenitic stainless steel (3xx series).

Buying steel from two suppliers usually leads to part vari- ations when forming in the same die, due to differences in mechanical properties. I recommend you obtain the chem- ical and mechanical properties of the problematic steel,

and for steel shipment that seems to perform better. This should indicate to the steel supplier the changes necessary to meet your requirements.

Normally, deep-drawn cups have four ears nearly equal in height, as produced by the die used to form the previous cup design. Two ears can be created by a special set of mean r-val- ues, but that is quite rare. Instead, an elliptical punch or die ring typically gets the call for generating two ears. The two locations of reduced wall clearance tend to iron the sheet thickness and extrude the ears up the punch wall.

Take two blanks and draw a line marking the rolling direc- tion. Place the first blank on the die with the line oriented front to back. Run the first blank, then place the second blank in the die with the line rotated 45 deg. from the first blank. If the ears rotate with the line, the problem is with the steel; if the ears remain oriented with the press direction, the die is the problem.

The breakage location in the dome results from a sharp change in punch radius when the hemisphere does not merge tangentially with the deep-draw cup wall. A severe strain gradient then creates a tear. The die impact or shock line first generated at this location moves up the deep- drawn cup area because the stretching of the hemisphere generates extra length of line that flows up the constant-diam- eter cup wall.

Sincerely,

Jim, formability engineer

Fig. 2—This problematic part had two large ears instead of four small ears; a tear where the bottom hemispherical portion was not tangent to the deep-drawn cup; and a die impact line above the cup/hemispherical bottom junction.

by the n-value) needed for the larger hemi-

The Science of Forming

COIL-FED FIBER LASER SYSTEMS

� ��� ���� ����������

� �� � ��� ������� ����� ���������

� �� �� ��� �� �������� �������

� ������� ����� � �������� �������� �����

US Patent: 6,563,081 Shown without fencing

Schedule a Demonstration Today (630) 773-4900 | www.therdigroup.com

www.metalformingmagazine.com

MetalForming/January 2014 39