Page 34 - MetalForming September 2014

P. 34

The Road to Plasma-Cutting Automation

supplier and wait a week for shipment, while paying more in the long run.”

Quick Switch from Automated to Manual

While Cornfield Customs largely ded- icates its new PAC system to automated cutting on its new table, the arrange- ment allows Wagner to quickly switch to manual cutting, thanks to a quick-dis- connect torch feature. This allows him to efficiently switch from the setup’s 180- deg. mechanized cutting torch to a 70- or 90-deg. manual torch. Software auto- matically detects which torch he has attached to switch between automatic and manual modes. This type of flexi- bility makes sense for Wagner, who often needs to manually cut one-off parts.

In addition, the power source offers a small connector on the back to con- nect to the CNC controls. This CNC interface connection gives Wagner sig- nals for start/stop, OK to move and divided arc-voltage.

Other features noted by Wagner

WEDNESDAY

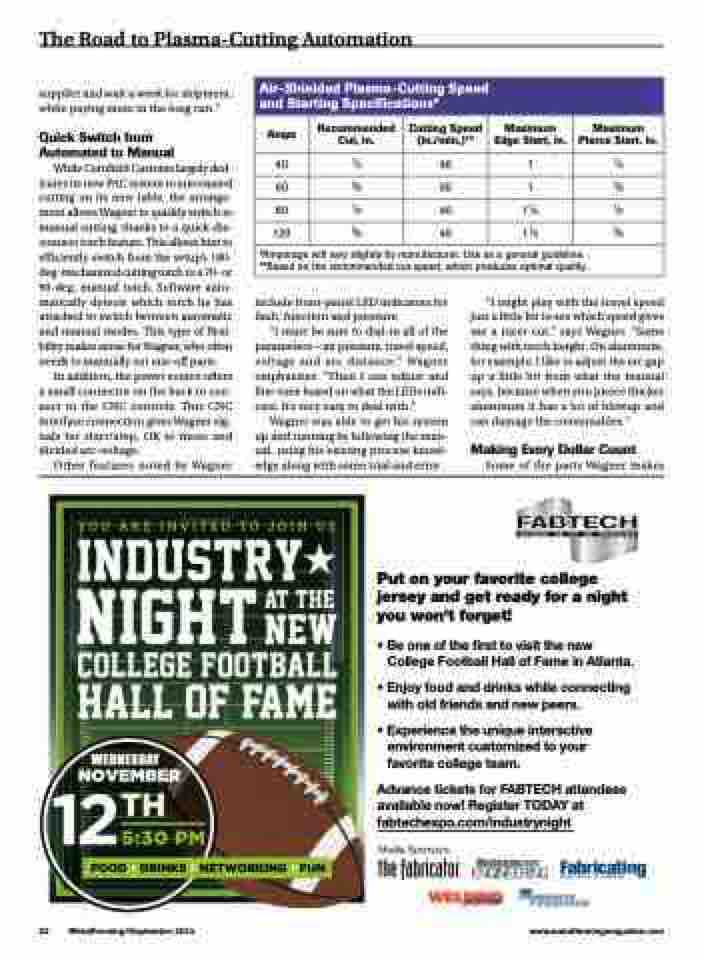

Air-Shielded Plasma-Cutting Speed and Starting Specifications*

32

MetalForming/September 2014

www.metalformingmagazine.com

Amps

Recommended Cut, in.

Cutting Speed (in./min.)**

Maximum Edge Start, in.

Maximum Pierce Start. in.

40 1⁄4 40 1 1⁄4 60 3⁄8 50 1 3⁄8

80 1⁄2 120 5⁄8

40 11⁄4 1⁄2

45 11⁄2 5⁄8

*Amperage will vary slightly by manufacturer. Use as a general guideline. **Based on the recommended cut speed, which produces optimal quality.

include front-panel LED indicators for fault, function and pressure.

“I must be sure to dial-in all of the parameters—air pressure, travel speed, voltage and arc distance,” Wagner emphasizes. “Then I can adjust and fine-tune based on what the LEDs indi- cate. It’s very easy to deal with.”

Wagner was able to get his system up and running by following the man- ual, using his existing process knowl- edge along with some trial and error.

“I might play with the travel speed just a little bit to see which speed gives me a nicer cut,” says Wagner. “Same thing with torch height. On aluminum, for example, I like to adjust the arc gap up a little bit from what the manual says, because when you pierce thicker aluminum it has a lot of blowup and can damage the consumables.”

Making Every Dollar Count

Some of the parts Wagner makes

Put on your favorite college jersey and get ready for a night you won't forget!

• Be one of the first to visit the new College Football Hall of Fame in Atlanta.

• Enjoy food and drinks while connecting with old friends and new peers.

• Experience the unique interactive environment customized to your favorite college team.

Advance tickets for FABTECH attendees available now! Register TODAY at fabtechexpo.com/industrynight

Media Sponsors: