Page 85 - MetalForming October 2012

P. 85

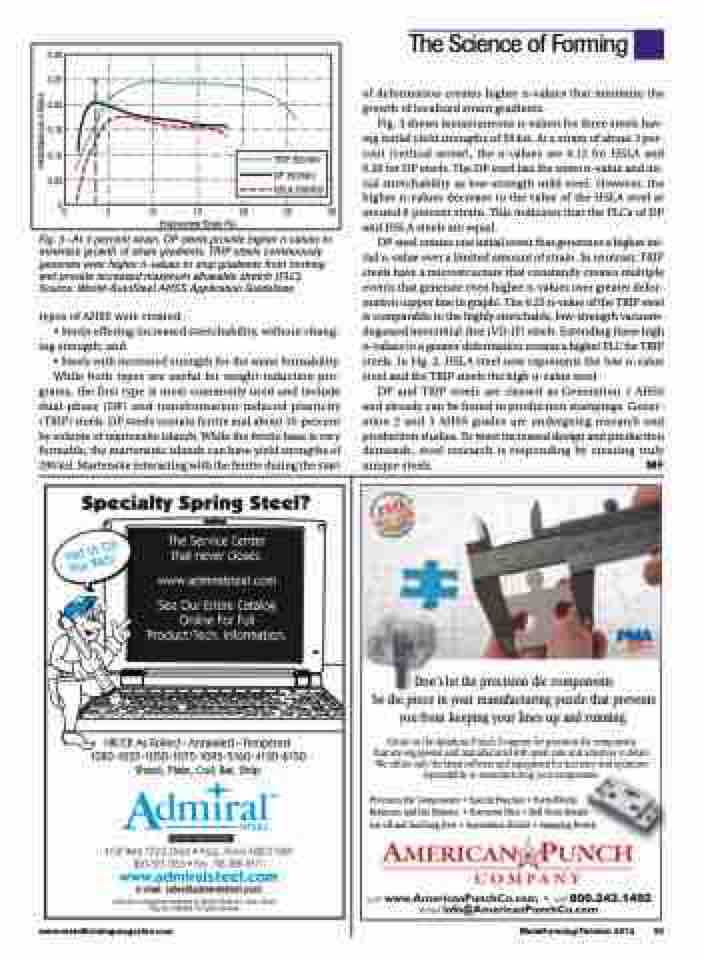

0.30 0.25 0.20 0.15 0.10 0.05

TRIP 350/600 DP 350/600 HSLA 350/450

The Science of Forming

of deformation creates higher n-values that minimize the growth of localized strain gradients.

Fig. 3 shows instantaneous n-values for three steels hav- ing initial yield strengths of 50 ksi. At a strain of about 3 per- cent (vertical arrow), the n-values are 0.12 for HSLA and 0.20 for DP steels. The DP steel has the same n-value and ini- tial stretchability as low-strength mild steel. However, the higher n-values decrease to the value of the HSLA steel at around 8 percent strain. This indicates that the FLCs of DP and HSLA steels are equal.

DP steel creates one initial event that generates a higher ini- tial n-value over a limited amount of strain. In contrast, TRIP steels have a microstructure that constantly creates multiple events that generate even higher n-values over greater defor- mation (upper line in graph). The 0.25 n-value of the TRIP steel is comparable to the highly stretchable, low-strength vacuum- degassed interstitial-free (VD-IF) steels. Extending these high n-values to a greater deformation creates a higher FLC for TRIP steels. In Fig. 2, HSLA steel now represents the low n-value steel and the TRIP steels the high n-value steel.

DP and TRIP steels are classed as Generation 1 AHSS and already can be found in production stampings. Gener- ation 2 and 3 AHSS grades are undergoing research and production studies. To meet increased design and production demands, steel research is responding by creating truly unique steels. MF

Don’t let the precision die components

be the piece in your manufacturing puzzle that prevents you from keeping your lines up and running.

Count on the American Punch Company for precision die components that are engineered and manufactured with great care and attention to detail. We utilize only the latest software and equipment for accuracy and optimum repeatability in manufacturing your components.

Precision Die Components • Special Punches • Form Blocks Retainers and Die Buttons • Extrusion Dies • Roll Form Details Cut-off and Notching Dies • Automation Details • Stamping Details

Instantaneous n-Value

00 5 10 15 20 25 30 Engineering Strain (%)

Fig. 3—At 3 percent strain, DP steels provide higher n-values to minimize growth of strain gradients. TRIP steels continuously generate even higher n-values to stop gradients from forming and provide increased maximum allowable stretch (FLC). Source: World-AutoSteel AHSS Application Guidelines.

types of AHSS were created:

• Steels offering increased stretchability, without chang-

ing strength; and

• Steels with increased strength for the same formability. While both types are useful for weight-reduction pro-

grams, the first type is most commonly used and include dual-phase (DP) and transformation-induced plasticity (TRIP) steels. DP steels contain ferrite and about 10-percent by volume of martensite islands. While the ferrite base is very formable, the martensitic islands can have yield strengths of 200 ksi. Martensite interacting with the ferrite during the start

www.metalformingmagazine.com

MetalForming/October 2012 83