Aluminum Large-Part Hybrid Manufacturing

November 18, 2021Comments

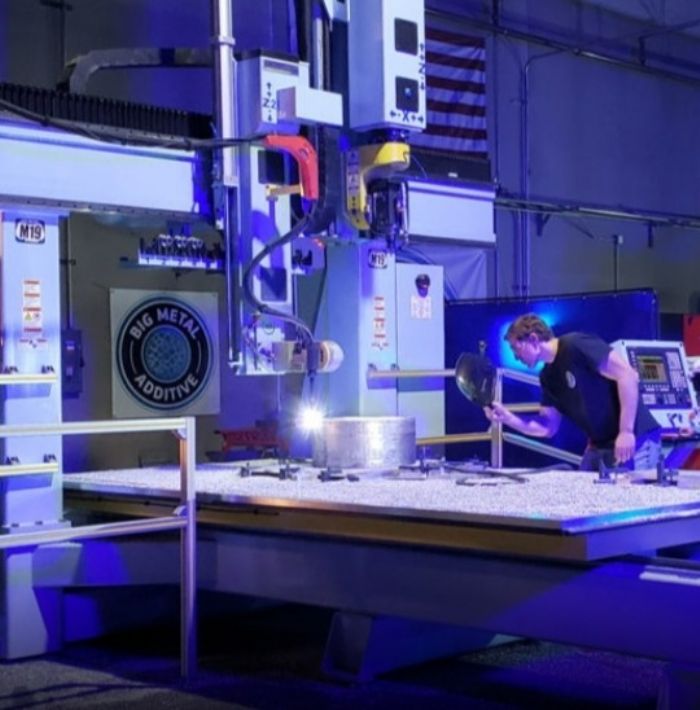

At Formnext...Big Metal Additive, Denver, CO, informed

showgoers on its capabilities in design adjustment and optimization, wire-fed additive

manufacturing (AM), and five-axis cutting and machining to produce chiefly

aluminum parts for customers. Aerospace, space, automotive and military

larger-part applications are ideal, as the company boasts 6 by 12-ft. AM worktables.

At Formnext...Big Metal Additive, Denver, CO, informed

showgoers on its capabilities in design adjustment and optimization, wire-fed additive

manufacturing (AM), and five-axis cutting and machining to produce chiefly

aluminum parts for customers. Aerospace, space, automotive and military

larger-part applications are ideal, as the company boasts 6 by 12-ft. AM worktables.

Big Metal Additive’s unique AM process provides interesting material properties according to the company’s general manager, Ty Stranger-Thorson, who filled in 3D Metal Printing on the technology at Formnext. Namely, the material exhibits full tensile strength at 0-, 45- and 90-deg. angles—atypical in layer-by-layer AM processes, where Z-axis tensile strength tends to suffer. And, the process combines additive and subtractive work on a single platform. This reportedly ensures dimensional integrity and consistent quality because each deposition layer is machined for cleanliness and dimensional control.

Founded by industry veteran Dr. Slade Gardner, who serves as president, Big Metal Additive has 12 employees.

See also: Big Metal Additive Inc

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Pressroom Automation

Pressroom AutomationProducing the New Aluminum-Intensive Porsche Taycan: Touring...

April 15, 2024

Video

Video Management

ManagementMetalForming LIVE: On the Shop Floor

Wednesday, April 24, 2024

Event

Event