LVD Debuts Robotic Bending Cell

May 23, 2024Comments

Belgium-based LVD Company nv, with

U.S. headquarters in Akron, NY, has introduced the Easy-Cell 80/25

robotic bending cell, which

features a built-in adaptive bending system

to ensure bend-angle accuracy from the first part. Also included: LVD’s advanced software for fast, simple offline programming of the press brake

and robot.

Belgium-based LVD Company nv, with

U.S. headquarters in Akron, NY, has introduced the Easy-Cell 80/25

robotic bending cell, which

features a built-in adaptive bending system

to ensure bend-angle accuracy from the first part. Also included: LVD’s advanced software for fast, simple offline programming of the press brake

and robot.

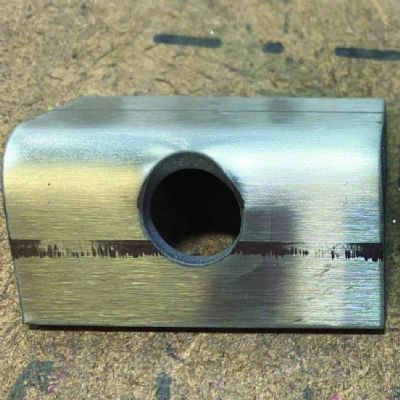

Cell components include an LVD Easy-Form 80-ton press brake with 2500-mm bend length and five-axis backgauge, and a Kuka industrial robot to handle parts from 100 by 100 to 1600 by 1200 mm and weighing as much as 25 kg.

The Easy-Form Laser adaptive, in-process bend-angle control compensates for material variations such as sheet thickness, strain hardening and grain direction. Scanners continuously measure the bend angle and transmit the information in real time to the CNC control for immediate adjustment of the punch position to achieve the correct angle.

View Glossary of Metalforming Terms

See also: LVD North America (Strippit Inc), KUKA Robotics Corp.

Technologies: Bending, Pressroom Automation