California Fabricator Ups Capacity and Capabilities With Combo Tube/Sheet Laser

January 22, 2025Comments

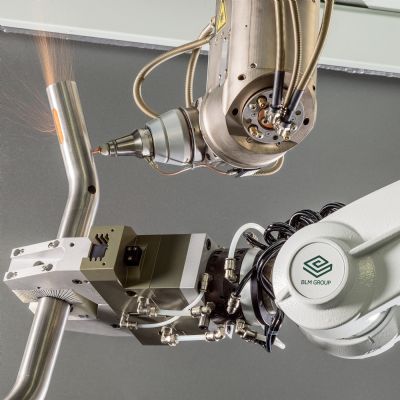

BLM Group USA has commissioned its LC5 combination tube and sheet laser cutting unit at Fast Trak Metal Fabrication (FTMF), a Fresno, CA, contract manufacturer. FTMF, which recently doubled its manufacturing footprint to 52,000 sq. ft., has reduced processing time by 50% with the new 10-kW hybrid machine as compared to its existing 4-kW CO2 machines. FTMF now has the capacity to cut tube, pipe and plate to 1.125 in. for steel, 1.5 in. for stainless steel and 1.375 in. for aluminum. In addition to gaining increased cutting capacity, FTMF can process high-volume flat-sheet laser cutting projects more efficiently with the addition of an automatic material loader/unloader.

BLM Group USA has commissioned its LC5 combination tube and sheet laser cutting unit at Fast Trak Metal Fabrication (FTMF), a Fresno, CA, contract manufacturer. FTMF, which recently doubled its manufacturing footprint to 52,000 sq. ft., has reduced processing time by 50% with the new 10-kW hybrid machine as compared to its existing 4-kW CO2 machines. FTMF now has the capacity to cut tube, pipe and plate to 1.125 in. for steel, 1.5 in. for stainless steel and 1.375 in. for aluminum. In addition to gaining increased cutting capacity, FTMF can process high-volume flat-sheet laser cutting projects more efficiently with the addition of an automatic material loader/unloader.

The technology addition has enabled the company to expand its customer base, as it now provides tube/laser service to the automotive-aftermarket and agriculture industries.

“Our team is ready to put the new tube/sheet laser machine to work as we continue to expand our customer base,” says Ferol Garcia, FTMF owner and CEO. “This machine is one of the main reasons that we doubled the square footage of our facility. The outlook for our business is optimistic in 2025, and we look forward to contributing more to the local economy through our expanded services with our new machine.”

“Our team is ready to put the new tube/sheet laser machine to work as we continue to expand our customer base,” says Ferol Garcia, FTMF owner and CEO. “This machine is one of the main reasons that we doubled the square footage of our facility. The outlook for our business is optimistic in 2025, and we look forward to contributing more to the local economy through our expanded services with our new machine.”

One major machine feature: The LC5 offers immediate switchover from tube to sheet without the need to reconfigure the machine, and effectively can process multiple material types and thicknesses.

View Glossary of Metalforming Terms

See also: BLM Group USA

Technologies: Cutting

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingSouthern States Machinery Named Exclusive Trumpf Distributor...

Monday, July 7, 2025