BeAM and CGTech Join Forces

September 10, 2018CommentsCincinnati, OH-based BeAM Machines, provider of directed energy deposition (DED) 3D printers and Irvine, CA-based CGTech, provider of CNC simulation and optimization software, have come together as technology partners.

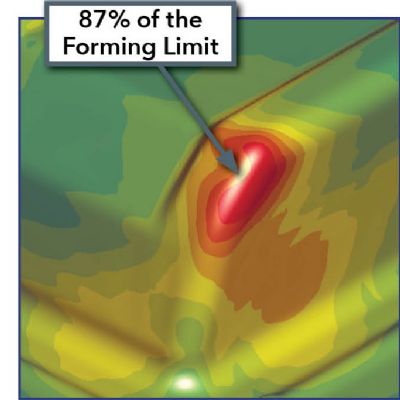

“The Vericut Additive module uses a digital twin of the workpiece and machine tool to simulate 3D-printing and hybrid processes,” explains Gene Granata, CGTech product manager. “Because it sees what the machine sees, it creates a layer of machine protection and simulation accuracy. This is especially important with high-speed five-axis machine tools such as BeAM’s, due to the part complexity and fast build rates made possible by their equipment. This is why we’ve become technology partners.”

“Vericut Additive reduces the amount of time needed for process development, and its simulation capabilities have helped us detect and avoid costly collisions,” says Tim Bell, engineering director at BeAM. “What’s more, it can be used for calculating cycle times in advance of the actual build, determining part feasibility.”

See also: CGTech Corporate Headquarters, BeAM Machines, Inc.

Technologies: