Automated Loading/Unloading Speeds Blank Production at Olympic Steel

May 29, 2024Comments

As presented in Blanking Line Supports Automotive’s Southeastern-U.S. Progression, a feature article appearing in the February Special Automotive issue of MetalForming, we detailed how the Windsor, GA, division of Olympic Steel added a blanking line to help support automotive manufacturing in the Southeastern United States. One key to the line’s effectiveness: automated blank loading/unloading courtesy of AP&T North America. New details on this automation have been provided on just how it can process the produced blanks, which vary greatly in shape and size.

As presented in Blanking Line Supports Automotive’s Southeastern-U.S. Progression, a feature article appearing in the February Special Automotive issue of MetalForming, we detailed how the Windsor, GA, division of Olympic Steel added a blanking line to help support automotive manufacturing in the Southeastern United States. One key to the line’s effectiveness: automated blank loading/unloading courtesy of AP&T North America. New details on this automation have been provided on just how it can process the produced blanks, which vary greatly in shape and size.

“Instead of developing everything from scratch, we chose to base the system on our tried and tested standard modules,” says Robert Leff, former mechanical solutions engineer with AP&T North America. “Our basic program of linear robots, SpeedFeeders, were perfect for the purpose.”

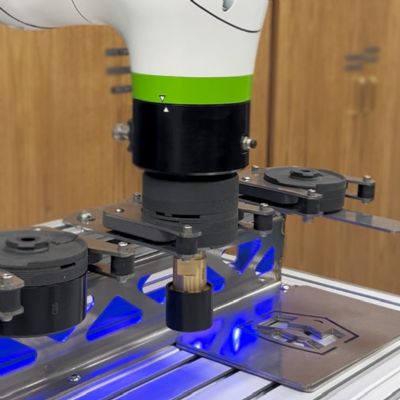

The automation, installed in the summer of 2022, included 12 positioning arms based on AP&T’s SpeedFeeders, a number of conveyors and two pallet stations that move automatically. Once the press—a 660-ton Stamtec eccentric-geared mechanical press—cuts a sheet metal blank, it is first moved to a telescopic conveyor and then to a magnetic conveyor. The positioning arms then ensure that each blank orients in the correct position. Finally, the blanks end up on a hydraulic scissor table that gradually lowers as the stack of components grows. With this automation, Olympic Steel has progressed from human operators handling blanks off of the press, thus limiting output, to having the line producing at maximum capacity. This setup also reduces the risk of personal injury.

“Automation of the stacking process has resulted in reduced manual labor requirements, minimizing the risk of human errors and enhancing the speed of production,” explains Ryan Hall, blanking manager at Olympic Steel. “Downtime related to manual handling has been reduced significantly, leading to increased overall output. We now often run our blanking line at, or close to, full speed, contributing to a more streamlined and efficient operation. Safety has increased due to the fact that human hands are not involved with the stacking process.”

The automation represents a novel experience for AP&T North America as well.

“Not only is this the first fully automated blanking line for Olympic Steel in Winder, but it is also the first stacking system of this type that we have designed,” says Johan Johansson, AP&T North America lead senior electrical and software designer.

See also: AP&T North America Inc., Stamtec, Inc., Olympic Steel, Inc., Olympic Steel

Technologies: Pressroom Automation

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Pressroom Automation

Pressroom AutomationPiab Introduces piClassic Neo Next-Gen Vacuum Pump

Tuesday, June 24, 2025

Pressroom Automation

Pressroom AutomationYaskawa America Announces Expansion and Relocation of North ...

Thursday, June 19, 2025

Pressroom Automation

Pressroom AutomationMagnetic Tool Changers and Transporters, and Lifting Magnets

Tuesday, June 17, 2025