“Partial hardening is not new to the North American market; many other companies do this,” Lehmann admits. “However, the TemperBox process is unique in its ability to form tight tolerances—a challenge that other similar processes often struggle with.”

Hot Stamping, Hot Situation

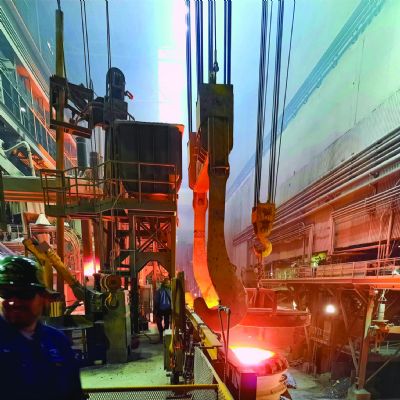

When Gedia, headquartered in Germany, decided to bring its hot stamping process to the United States, it encountered more than the usual challenges of establishing a new plant. The task required producing hot-stamped structural components to customer specifications using a press that had to be built, all within a tight timeline. This was further complicated by setting up a new plant in a foreign country during a pandemic. Needless to say, the 930 C temperature in the oven wasn’t the only heat the company had to endure.

When Gedia, headquartered in Germany, decided to bring its hot stamping process to the United States, it encountered more than the usual challenges of establishing a new plant. The task required producing hot-stamped structural components to customer specifications using a press that had to be built, all within a tight timeline. This was further complicated by setting up a new plant in a foreign country during a pandemic. Needless to say, the 930 C temperature in the oven wasn’t the only heat the company had to endure.

Just as the manufacturer received the purchase order from its current customer in December 2019, the entire company was hit with a cyberattack in January 2020.

Just as the manufacturer received the purchase order from its current customer in December 2019, the entire company was hit with a cyberattack in January 2020.

Shortly after that attack, COVID-19 struck, leading to a period of restricted in-person contact, widespread use of video conference calls, extended illnesses and absences, international travel restrictions, transportation halts, supply-chain disruptions, and overall limitations.

“This ‘little’ thing called COVID made everything very difficult,” Lehmann comments.

Bernd Maiworm, the Gedia plant manager during the launch (scheduled to return to Germany in June 2024), relays some of the challenges.

“The original plan was to have experienced, skilled tradespeople travel to the United States to train new machine- and die-maintenance technicians, but that plan was thwarted,” he says. “Due to COVID, the consulate in Frankfurt was closed, so, early on, we could not apply for the visa to come to the United States. At one point during the COVID outbreak, the complete construction site sat idle for 12 days.”

In addition, company employees had to run operations while the building went up around them. “Timing was very tight, and, therefore, we had to be very creative,” Maiworm adds. “Normally, you would have the building ready and then start bringing in the machines. We did everything in parallel. Construction occurred while we installed the equipment, built assembly lines and started with the first tryout.” Before installing an overhead crane in the high bay, the team brought in a mobile crane to help with all of the tryouts.

With the high-bay part of the building constructed, the crew erected a temporary wall between it and where the low bay would be located while no permanent wall existed. (On the plus side, the company did not have to cut a hole in the roof to bring in a new press crown.)

With the high-bay part of the building constructed, the crew erected a temporary wall between it and where the low bay would be located while no permanent wall existed. (On the plus side, the company did not have to cut a hole in the roof to bring in a new press crown.)

“Coordinating all installations and operations during building construction required meticulous scheduling,” Maiworm explains. “Determining the timing for bringing in specific machinery and coordinating it with construction activities were significant challenges.”

“Our quality lab was upstairs in the high-bay building while the low-bay interior building was being completed,” Frakes adds. “We had to hand-carry a lot of equipment and components up and down the stairs every day.”

“Our quality lab was upstairs in the high-bay building while the low-bay interior building was being completed,” Frakes adds. “We had to hand-carry a lot of equipment and components up and down the stairs every day.”

Frakes reflects on the most challenging aspect: “Building the staff during the pandemic, particularly in a region known for its carpet industry rather than an established automotive industry, posed significant hurdles in terms of finding the right skill sets. Personally, it felt like starting from ground zero, establishing a plant while sourcing and training good people with limited in-person contact. However, through this journey, we’ve developed the team we have today, which is truly world-class.”

To Customer Requirements, Timetable

Mercedes, the OEM for which the plant was built to supply, required the parts on its timetable, regardless of the circumstances, for its newly developed EQE and EQS electric sport utility vehicles. The contract agreement entailed delivering the first pre-series parts in October 2021.

“We broke ground in September 2020. The first successful run was in May 2021. By late September of that year, we shipped the first pre-serial parts to Tuscaloosa, AL,” Maiworm explains.

“Ultimately, the team pulled together and we made it happen, Frakes concludes. “We didn’t miss a date.” MF

View Glossary of Metalforming Terms

See also: AP&T North America Inc., TRUMPF Inc.

Technologies: Stamping Presses

“We hot-stamp crash-relevant structural parts and produce assemblies, such as A- and B-pillars, roof rails, crossmembers, and firewalls,” says Maggie Frakes, who recently assumed the role of operational plant director of the Dalton plant after serving in various roles within the company.

“We hot-stamp crash-relevant structural parts and produce assemblies, such as A- and B-pillars, roof rails, crossmembers, and firewalls,” says Maggie Frakes, who recently assumed the role of operational plant director of the Dalton plant after serving in various roles within the company. “We’ve maintained a 100% scorecard in quality and logistics with our customer for 19 mo.,” she adds.

“We’ve maintained a 100% scorecard in quality and logistics with our customer for 19 mo.,” she adds. “Our unique hot stamping feature is the TemperBox process,” says Michael Lehmann, CEO of Gedia North America, describing the patented technology from AP&T for partial press hardening of structural parts for passenger cars. “This partial hardening process allows us to vary the material strength in specific sections, making it harder or softer as needed. This enables us to combine hard and soft zones within a single part.”

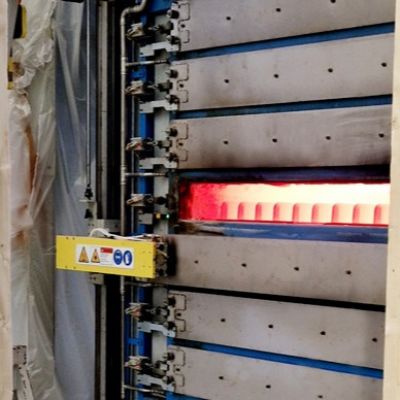

“Our unique hot stamping feature is the TemperBox process,” says Michael Lehmann, CEO of Gedia North America, describing the patented technology from AP&T for partial press hardening of structural parts for passenger cars. “This partial hardening process allows us to vary the material strength in specific sections, making it harder or softer as needed. This enables us to combine hard and soft zones within a single part.” Frakes elaborates: “The process involves precision-controlled heat treatment, carried out in a multilayer oven with the TemperBox furnace.” Initially, each blank is heated to 930 C in one of the upper layers of a conventional austenization furnace. Blanks then transfer to the furnace module in the oven’s lower layer. A masking technique blocks radiation and heat in specified sections of each blank, cooling them down while keeping the rest of the part hot. Finally, blanks are formed and quenched to produce the finished parts.

Frakes elaborates: “The process involves precision-controlled heat treatment, carried out in a multilayer oven with the TemperBox furnace.” Initially, each blank is heated to 930 C in one of the upper layers of a conventional austenization furnace. Blanks then transfer to the furnace module in the oven’s lower layer. A masking technique blocks radiation and heat in specified sections of each blank, cooling them down while keeping the rest of the part hot. Finally, blanks are formed and quenched to produce the finished parts.

Event

Event