Identification stamps, typically used to mark batch numbers, cannot realistically generate a unique identifier on each part—to do so would require unique hardware and greatly slow stamping operations as ID stamps must be updated for each part.

To meet OEM traceability requirements, metal stampers must seek another solution. That solution: laser marking systems. These systems allow manufacturers to move away from batch numbers and implement unique traceability identifiers without slowing down production lines. Unique codes can include a variety of information that provides greater traceability, such as:

To meet OEM traceability requirements, metal stampers must seek another solution. That solution: laser marking systems. These systems allow manufacturers to move away from batch numbers and implement unique traceability identifiers without slowing down production lines. Unique codes can include a variety of information that provides greater traceability, such as:

- Part number

- Serial number

- Lot number

- Model number

- Production data and time

- Facility

- Source.

Upon discovery of a problem downstream, this marking capability enables more rapid tracing of part production back through the supply chain to identify defect patterns.

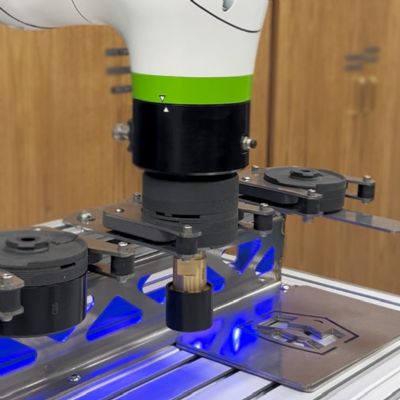

To generate a unique data matrix code for each stamped part, the laser marking system communicates with a stamping press controller (such as a PLC or PC) to obtain the traceability information for marking on each part—a completely automated process with parameters updated within a few milliseconds.

Advantages When Marking at Production Start

To meet modern OEM traceability requirements, part suppliers must mark parts at the start of production. Doing so presents technical challenges for metal stampers, but laser marking systems are up to the task, delivering speed and durability.

Stamping presses can produce parts at lightning speed, sometimes exceeding 60 parts/min., and speed of production in metal stamping directly correlates with profitability. To keep presses humming, a marking system must identify a part rapidly—in less than 1 sec. for operations exceeding 60 parts/min. Laser marking systems keep up with this production level beyond what other methods can accomplish, with capabilities to impart data matrix codes on each part in as quickly as 0.6 sec.

Another challenge with marking parts at the start of production: durability. In stamping production lines, several processes performed downstream can affect the readability of identifiers and impact traceability. E-coating and the stamping presses themselves can modify the shape of identifiers or obscure them behind coatings, making them difficult to read.

The laser marking process excels in meeting such challenges, as lasers can be adjusted to overcome these obstacles. Laser-marked identifiers can withstand ecoating, stamping and other processes, and can be fine-tuned for specific traceability needs.

Another challenge: Most metal formers stamp parts from coils and blanks, and marking individual parts at the exit of the press proves difficult due to the various part configurations. Laser marking can be used to mark coils or blanks before they enter the stamping press, thus preventing complex part handling, and ultimately saving on costs while ensuring that marking doesn’t slow the stamping process.

Use Industrial-Grade Laser Markers

Metal stampers cannot afford costly downtime for extended maintenance or stoppages due to equipment breakdowns. Stamping lines require the use of industrial-grade laser markers that can handle these harsh environments and stand up over time.

For example, surfaces of blanks and coils are often oily, which means that oil and dust particles will release into the air during laser marking. Laser markers must offer protection against dust and liquids to avoid contamination or degradation. As such, manufacturers should ensure that their laser marking systems have three key features:

- IP rating. The laser IP (ingress protection) rating, an international rating, indicates how well laser enclosures resist water and dust. High-volume production processes such as metal stamping generally should use lasers with an IP rating of 54 or above.

- Fume extractor. Laser fume extractors suck up the fumes created during the process and reduce hazardous fumes and particulates. Fume extractors also should perform proximity source capture. Ensure this by positioning the fume-extraction nozzle as close as possible to the source of dust and fumes.

- Air knives/Air blowers. Debris and contamination on the laser lens can cause significant problems. It can degrade performance and lead to marking-quality defects. Air knives, also known as air blowers, deflect debris away from the laser lens. They blow air in front of the lens continuously to prevent dust accumulation and minimize maintenance.

Complete Traceability: Win-Win for OEMs and Part Suppliers

Considering that the average vehicle may have as many as 20,000 to 30,000 parts, we quickly see how challenging part marking can be, but also its importance.

Recalls, expensive for OEMs and their suppliers, make complete traceability essential for reducing such costs and tracking production processes. An efficient traceability program with the help of laser marking produces significant benefits by:

- Improving quality control at a granular level

- Ensuring authenticity and fighting back against counterfeit parts

- Recognizing and tracking problems across supply chains, suppliers, materials and production runs

- Boosting efficiency and reducing waste

- Meeting strict OEM compliance mandates.

Implementing complete traceability, though no easy task, is essential in today’s environment. By using lasers, metal formers can provide traceability that helps benefit and safeguard every link in the supply chain. MF

See also: Laserax

Technologies: Cutting, Pressroom Automation

Automotive OEMs long have pushed implementation of complete traceability in their supply chains, and strict OEM traceability requirements increasingly have become standard operating procedures. More and more OEMs request that parts be marked at the start of production and that every part wear a unique identifier.

Automotive OEMs long have pushed implementation of complete traceability in their supply chains, and strict OEM traceability requirements increasingly have become standard operating procedures. More and more OEMs request that parts be marked at the start of production and that every part wear a unique identifier.

To meet OEM traceability requirements, metal stampers must seek another solution. That solution: laser marking systems. These systems allow manufacturers to move away from batch numbers and implement unique traceability identifiers without slowing down production lines. Unique codes can include a variety of information that provides greater traceability, such as:

To meet OEM traceability requirements, metal stampers must seek another solution. That solution: laser marking systems. These systems allow manufacturers to move away from batch numbers and implement unique traceability identifiers without slowing down production lines. Unique codes can include a variety of information that provides greater traceability, such as: