Automation Solutions for Roll Forming

May 21, 2019Comments

Samco Machinery, Toronto, Ontario, Canada, supplies roll forming machines and related products. Don Fanstone, the company’s senior manager, provides examples of control and material-handling solutions that allow roll formers to get the most out of their lines.

|

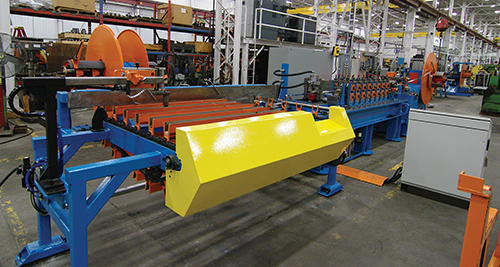

| An automated count and stacking mechanism eliminates the need for operators to stop the line for part counting. |

Presented here: two examples of new technology in action.

Automated Part Stacking and Counting Mechanism

A drywall cornerbead manufacturer recently upgraded a production line to a significantly higher operating speed. It did not take long to realize that one operator would not be able to stack, count the number of pieces to be boxed and staple the carton at the increased machine speed. Instead, the operator found it necessary to stop the line to double check the number of parts.

Using an automated count and stacking mechanism, periodic unscheduled line stoppage stopped. With increased machine speed and automated material handling of the upgraded line doing the counting and stacking of the parts, one operator now can insert and seal parts into a carton, boxing bundles of 20, 25 or 30 pieces without having to stop to check the count. As a result, production soared standpoint, eliminating manual handling of each part averted potential carpal-tunnel injury.