Die casting and other traditional manufacturing processes can produce millions of components per year, while AM processes such as LPBF can excel and add value by delivering geometric complexity with the least amount of material possible, but not economically at high volumes. This has long been a trade-off, one that has seen automotive companies dismiss AM for production applications—but such thinking is changing.

Case Study: Automotive LED Headlights

|

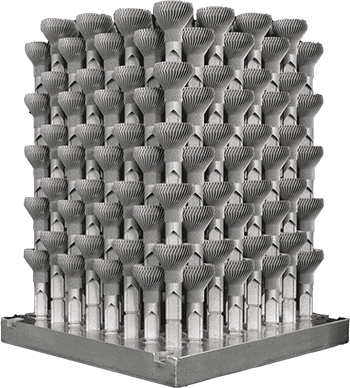

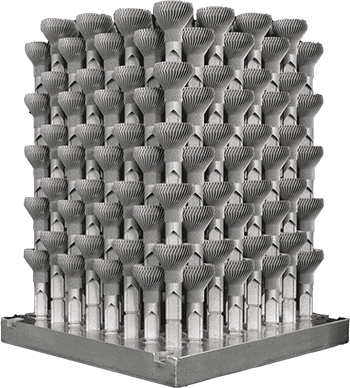

| A stacked build of automotive LED-headlight heatsinks. Designing the part with in-built support features allowed multiple parts to be stacked on top of each other without the need for additional supports. As a result, finished parts could be snapped apart by hand, without the need for further post-processing. |

The right part can help industry break conventional thinking about LPBF. A demonstration can be found in the automotive industry’s switch to the use of LED headlights. Typically, these components require comparatively large, often actively cooled heatsinks. Betatype, which works with customers to deliver functional components through AM, and built Engine, a data-processing platform for managing and controlling multi-scale design, saw an opportunity. The company recognized that the specific geometry for these metal parts made them ideal for producing via LPBF, which can consolidate multiple manufacturing processes into a single production method.

By considering the LPBF process during the component’s initial design stage, Betatype was able to design a part with in-built support features, allowing multiple headlight parts to be stacked on top of each other without the need for additional supports. As a result, finished parts could be snapped apart by hand, without the need for further post-processing.

Full stacking, often deemed difficult with LPBF due to thermal stresses involved in the layer process, was achieved through intelligent design of the structure. This reduced thermal stresses, leading to minimal thermal distortion. Innovative part design enabled a series of parts to be nested to maximize build volume, resulting in 384 parts produced within a single build envelope. UK-based Progressive Technology built the parts using an EOS 280M system.

Reduced Build Times and Costs

Betatype’s design and data-processing technology enabled every toolpath within each part to be designed, managed and optimized. Through specific control parameters, exposure of the part in each layer to a single laser-melting toolpath was reduced significantly, with minimal delays in between. This, coupled with the company’s optimization algorithms and process technology, reduced build time of each part from 1 hr. to less than 5 min. —reportedly 10 times faster than using a standard build processor.

Reducing build times is key to making parts more cost-effective with LPBF, as equipment amortization represents a major part-cost driver. Betatype’s optimization technology played a significant role here in decreasing cost/part from $40-plus to less than $4.

Moreover, on single-laser, medium-frame printing systems, this technology helped reduce build time from 444 hr. to less than 30 hr. for the 384 parts. With new multi-laser, medium-frame systems this optimization approach reduced build time to less than 19 hr. Using these high-productivity systems, it was possible to realize a 19-fold gain in productivity across a year of production per system, from 7055 to 135,168 parts. Installation of seven machines running the optimized process results in volumes approaching 1 million parts/yr. 3DMP

Article supplied by Betatype, London, United Kingdom; www.betaty.pe.

See also: EOS of North America, Inc., Betatype

Technologies: