Handling ‘Hot’ Parts

Lundy, commenting on a blog residing on the Optimation website titled, “8 Nesting Best Practices to Gain Productivity,” stresses the importance of dynamic batch nesting, so that fabricators can seamlessly and efficiently adjust their nests on the fly, during a shift. One best practice noted in the blog: Automatic batch nesting allows a fabricator to develop, just in time, optimal nests that consider the real-world manufacturing environment with all of its competing priorities, including ‘hot’ parts.

“With traditional batch nesting, when the orders for a particular shift change,” Lundy says, “and now include ‘hot’ parts that weren’t originally included on the nests, some of the nests that have yet to be produced must get called back and the ‘hot’ parts added. These nests must be reproduced with a new set of requirements, and that’s where dynamic nesting—and in particular automated just-in-time (JIT) nesting—comes into play.”

JIT nesting differs from traditional dynamic batch nesting in that it allows a fabricator to make adjustments to nests from one cycle to the next, by not ever building a batch nest. Instead, the nesting software allows the fabricator to automatically generate and deliver the next nest to the machine (a laser or turret press, for example) just before it finishes its current nest. So, with every machine cycle the fabricator can adapt to changing requirements on the shop floor.

“With JIT, a nest doesn’t get built until the machine is ready to run it,” Lundy says. “The nesting software draws from the active orders—including up-to-the minute changes and with ERP input as well—and creates the next nest. For example, consider a shop nesting in batch mode and running three lasers. If one of the machines goes down, there would be a series of nests backlogged; some might even include hot parts. With JIT nesting, the most important parts run through the remaining two machines automatically, avoiding production delays.

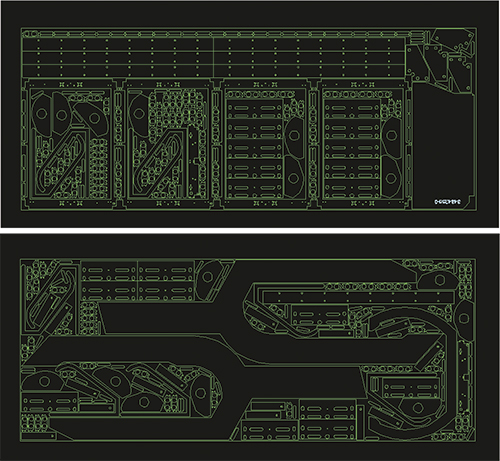

|

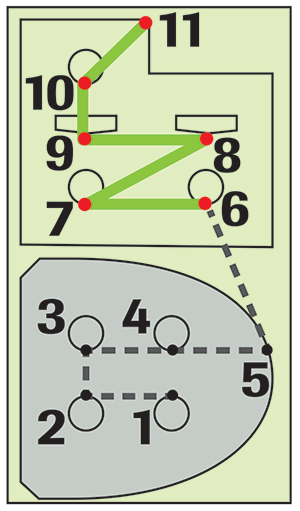

| Nesting software with built-in collision avoidance creates nests and cutting procedures that avoid part tip-up and sheet buckling. The trick to collision avoidance: sequencing the tool path to minimize the number of times the cutting head must raise up to safely pass over previously cut paths and parts, which delivers the added benefit of eliminating slow z-axis motion that adds to processing time. |

“We’re seeing shops generate complex nests in less than 5 min.,” he adds. “This proves very challenging to the nesting software, which has to account for schedules, machine requirements and material efficiency. And, we see that JIT nesting improves material efficiency compared to batch nesting, because with batch nesting, fabricators will experience ‘tail-off’ where the last sheet in the run won’t be completely filled with parts, often creating remnants…and waste. With JIT nesting we can avoid the tail-off issue.”

Order Cohesion

Another important consideration in managing chaos is order cohesion—the ability to schedule parts in a timely manner to ensure optimum downstream processing, such as welding of a subassembly, where all of the parts required for the subassembly must arrive simultaneously (or nearly so) at the weld station.

“Nesting should keep parts within one order together, whether they’re processed on the same machine or on different machines in the shop,” says Lundy. The previously referenced blog post refers to this practice as “intelligent order management” in that the nesting software knows which parts belong together in an order, and which orders have priority.

“Further,” it states, “JIT kit nesting addresses the needs of keeping all of the parts of a single assembly together, so that they can flow through the shop as a unit. Through intelligent nesting, material efficiency can be managed to eliminate the end-of-kit tail-off and additionally reduce material waste.”

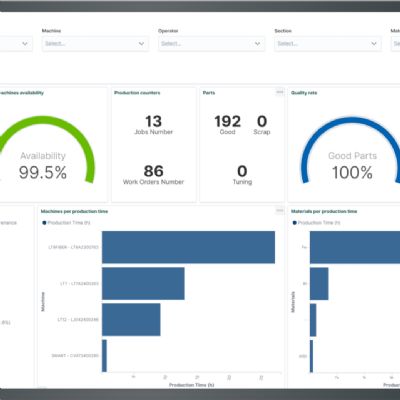

Lundy adds that JIT nesting typically boosts material efficiency by 10 percent or more compared to batch nesting. “And, the speed pickup in material flow through the shop is significant as well,” he says. “Fabricators often can progress from design to order to machine in 5 to 10 min. And, we’ve seen machine green-light times increase as a result—lasers running at 60 to 70 percent green-light time can improve to 90 percent, and turret presses running at a green-light time of 30 to 40 percent can improve to 70 or 80 percent.”

Manufacturable Nests

Lundy then points to another real-world demand that nesting software and those that use it must account for: Can the equipment on the shop floor produce the nests as programmed? Nesting must account for machine requirements such as reach, repositions, the number of tooling stations and kerf allowances to ensure not only production efficiency but also part quality, while avoiding machine damage and protecting workers.

“Nesting software can ensure that tool paths retain sufficient material integrity to hold the sheet together throughout the machine cycle,” says Lundy, “by carefully designing the microjoints between the parts on the nest. This so-called ‘intelligent tabbing’ helps to safeguard the machine and the operator, by ensuring that the skeleton won’t fall apart before parts are off-loaded.

“We also can make the clamps essentially disappear,” Lundy adds, “by nesting and programming machine action to punch where the clamps will be moving to, and then moving the clamps to that previously punched or cut location and punching where the clamps already have been. And, there’s built-in collision avoidance (particularly useful during plasma, laser and waterjet cutting),” he continues, “so that nests and cutting procedures are developed to avoid part tip-up and sheet buckling.”

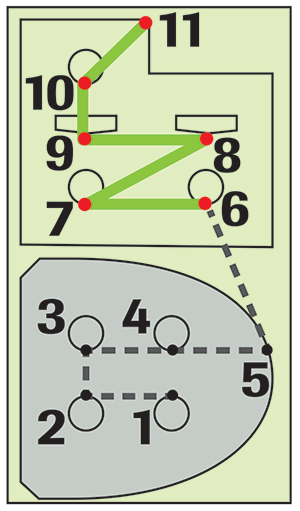

The trick to collision avoidance: sequencing the tool path to minimize the number of times the cutting head must raise up to safely pass over previously cut paths and parts. This delivers the added benefit of eliminating slow z-axis motion that adds to processing time. In most applications, the nest should create tool paths that progress from the innermost cuts out toward the skeleton.

More on Safety

Describing an additional safety feature, Lundy notes that modern nesting software helps to protect operators from the molten spatter that can be ejected from a thermal-cutting machine when piercing thick work. Here, an ideal nest will control the direction of the spatter away from the machine operator.

“First, we want to pierce on the fly,” says Lundy. “Then, we create the nests, automatically, so that the lead-ins point away from the operator. We make this a constraint with the software, rather than a nesting parameter; it’s an absolute within the knowledge base.” MF

See also: Optimation Software Products

Technologies: Software