HP Report: AM Key to Agility and Supply-Chain Growth

October 21, 2020 Stay informed with the 3D Metal Printing newsletter

| HP Report: AM Key to Agility and Supply-Chain Growth |

“The global manufacturing sector is clearly signaling a desire for greater supply-chain resiliency, more manufacturing flexibility, increased speed of innovation and stronger environmental sustainability,” says Ramon Pastor, general manager of HP 3D Printing & Digital Manufacturing, commenting on a new industry report. “And, they see industrial 3D printing as a way to not only lower costs and go to market faster, but as a unique competitive advantage that accelerates innovation for customers.”

Other findings in the HP report, from a survey conducted this summer of

3D printing and digital manufacturing decision makers from around the

world:

- During the next 12 mo., 71 percent of respondents plan on investing

in digital manufacturing technologies, and more than 85 percent plan to

increase their AM investment.

- 75 percent report that additive manufacturing (AM) helps their company be more agile.

- More than 90 percent report investigating new production/supply

chain models, with 59 percent evaluating hybrid models and 52 percent

exploring localized production.

|

|

|

|

|

|

|

|

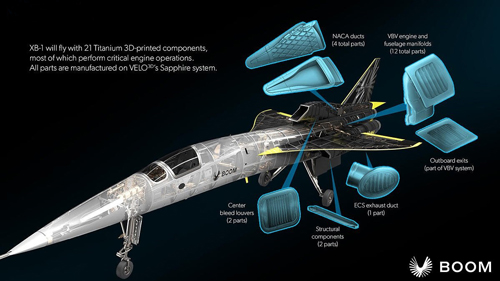

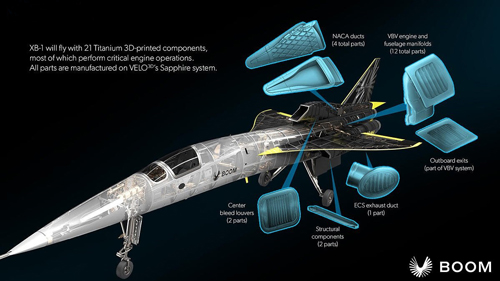

| XB-1 Supersonic Jet Loaded with 3D-Printed Titanium Parts |

| The

newly revealed Boom Supersonic XB-1 aircraft includes 21 3D-printed

titanium flight-hardware components, manufactured with the Velo3D

Sapphire 3D metal printer. The printed parts, used for engine-hardware,

environmental-control-system and structural components, feature tall,

thin walls with high aspect ratios. Boom Supersonic and Velo3D announced

a partnership in 2019 to manufacture complex flight hardware to build

the XB-1, and ran a series of qualification trials on the Sapphire,

leading to inclusion of the parts in the aircraft. |

|

|

|

|

|

|

|

|

|

| In This Issue |

| Wire-Directed Energy Deposition Technology |

Wire

directed energy deposition (wire-DED) additive manufacturing (AM)

technology employs metallic wire as the feed stock, and either an

electric arc, laser or electron beam as the energy source.

Teach Engineers to Understand the Business Case

…for metal AM to help convince decision makers that investing in the technology will pay off quickly. Building a business case on the foundation of purchase-price variance will put teeth to more familiar concepts such as improved product performance and speed to market. |

|

|

|

|

|

|

|

|

| Coming in 3DMP's Fall 2020 Issue |

- Software for Metal AM

- Laser DED

- Quality Control

- Machine Learning for 3D Printing

|

|

|

|

|

|

Technologies:

Quality Control

Quality Control

Event

Event