Gas-Reduction Nozzle Technology for Mitsubishi GX-F Fiber Lasers

January 29, 2024Comments

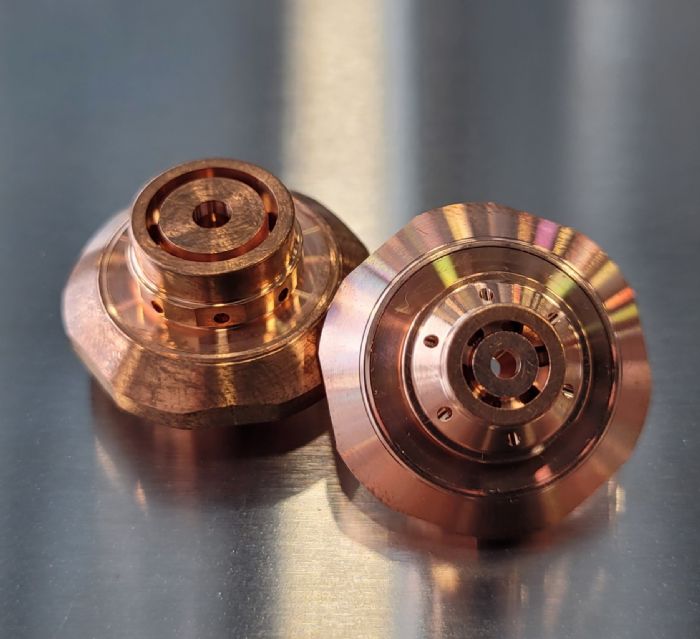

Now available through MC Machinery is Mitsubishi Laser’s new gas- and burr-reduction technology, AGR-Mix, for the Mitsubishi GX-F Advanced series of artificial-intelligence-enabled fiber lasers. AGR-Mix nozzle technology, which reportedly improves cut quality while reducing gas consumption when cutting mild steel, does not require expensive external blending tanks or high-pressure oxygen. The AGR-Mix features a unique structure: Nitrogen is funneled to the center of the nozzle in an air shroud, while a separate chamber funnels some of that air into the nitrogen stream. This produces a mix gas composed of about 95% nitrogen and 5% oxygen.

Now available through MC Machinery is Mitsubishi Laser’s new gas- and burr-reduction technology, AGR-Mix, for the Mitsubishi GX-F Advanced series of artificial-intelligence-enabled fiber lasers. AGR-Mix nozzle technology, which reportedly improves cut quality while reducing gas consumption when cutting mild steel, does not require expensive external blending tanks or high-pressure oxygen. The AGR-Mix features a unique structure: Nitrogen is funneled to the center of the nozzle in an air shroud, while a separate chamber funnels some of that air into the nitrogen stream. This produces a mix gas composed of about 95% nitrogen and 5% oxygen.

Combining low-pressure air with nitrogen within the nozzle creates a blended gas that easily can be adjusted based on material type, according to Mitsubishi Laser officials. And, the wider kerf that mix gas provides eases removal of parts (especially thick parts) from skeletons.

To develop AGR-Mix, Mitsubishi Laser built on its no-contact AGR (Assist Gas Reduction) nozzle technology, which reduces nitrogen-assist gas consumption by as much as 75%. AGR-Mix now reportedly can reduce such consumption even further, to 50% more.

See also: MC Machinery Systems

Technologies: Cutting

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Cutting

CuttingSouthern States Machinery Named Exclusive Trumpf Distributor...

Monday, July 7, 2025

Cutting

CuttingLaser Cutting Automation With Smart Material Handling

Wednesday, June 18, 2025

Cutting

CuttingAtaco Steel Products Names Steger VP of Operations

Thursday, June 12, 2025