Simple Setup, Heavy-Duty 2D Cutting

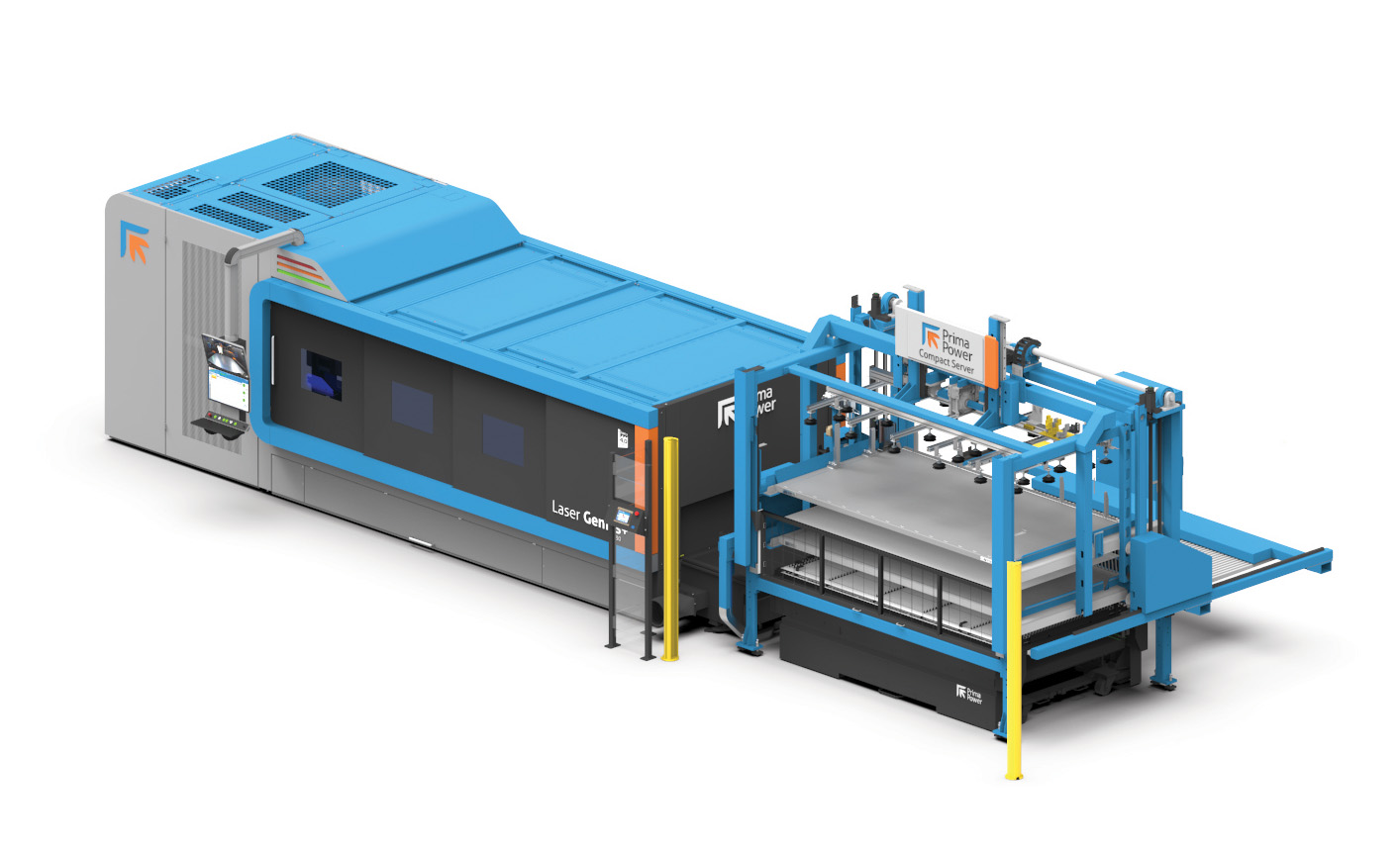

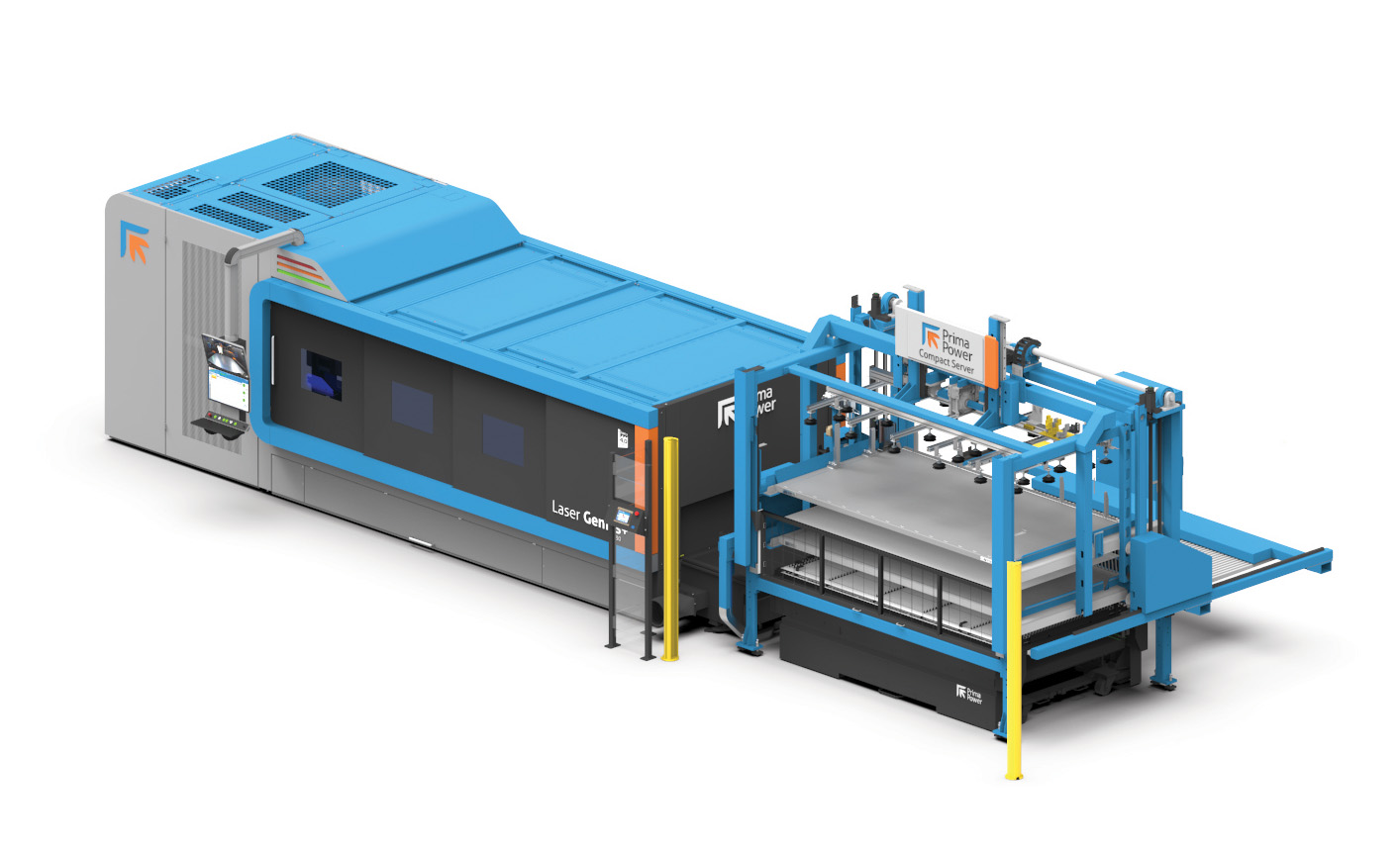

Prima Power featured the Laser Genius+ with Compact Server, developed to cut large and heavy workpieces precisely and at high speeds. Rated to a trajectory speed of 180 m/min. and acceleration of 2.8 g, the 2D-cutting machines come in three sizes and with a range of laser powers to satisfy a variety of application needs. Maximum X-Y-axis travel: 6320 by 2200 mm. Integrated software modules simplify processes, and artificial-intelligence algorithms provide advanced monitoring and process-control functions.

Prima Power featured the Laser Genius+ with Compact Server, developed to cut large and heavy workpieces precisely and at high speeds. Rated to a trajectory speed of 180 m/min. and acceleration of 2.8 g, the 2D-cutting machines come in three sizes and with a range of laser powers to satisfy a variety of application needs. Maximum X-Y-axis travel: 6320 by 2200 mm. Integrated software modules simplify processes, and artificial-intelligence algorithms provide advanced monitoring and process-control functions.

This plug-and-play machine provides for rapid install times and features a symmetrical and reversible layout that increases ergonomics and ease of integration into any production context. It includes two 24-in. full-HD monitors and a 4K video camera as standard, as well as integrated software modules that simplify processes, new sensors, and artificial-intelligence algorithms for advanced monitoring and process-control functions. The Laser Genius+ can be connected to the range of Prima Power automation systems. At FABTECH, the machine was shown with the Compact Server automatic loading and unloading device for raw and processed sheets—a compact configuration that provides flexible material handling.

Entry-Level Laser Cutting Promises Quick Setup, Simple Use

BLM Group unveiled its latest lineup addition, the LS7 sheet laser cutting machine, designed as an entry-level product in the high-end system segment, according to BLM Group officials, and capable of employing laser power to 12 kW.

BLM Group unveiled its latest lineup addition, the LS7 sheet laser cutting machine, designed as an entry-level product in the high-end system segment, according to BLM Group officials, and capable of employing laser power to 12 kW.

The machine features a conventional aluminum mobile gantry structure actuated by a rack-and-pinion system, which slides on a steel base filled with a special polymer to ensure high rigidity even with accelerations to 2 g. And, pallet change reportedly can be accomplished in only 9 sec. on the long side of the machine, with this high speed attainable via an ability to anticipate the simultaneous exchange of the two tables. Handling is fully electric, without pneumatic or hydraulic actuators, for optimum maintenance and energy usage.

The LS7 can cut steel, stainless steel, iron, copper, brass and aluminum in thicknesses from 0.20 to 1.57 in. or even double sheets, depending upon the material and selected laser power. It’s available in two versions: the 3015, with a maximum sheet size of 121.5 by 62.2 in.; and the 4020, capable of handling sheet sizes to 162.5 by 79.5 in. Users can add automatic sheet loading and unloading with one or two storage towers for automated material changeovers, making the setup well-suited for unmanned operations.

Other LS7 features: plug-and-play operations that enable simplified equipment setup, and eased integration with ERP systems as well as material-handling and storage systems. The cutting process can be monitored by windows near the operator console or by optional cameras located inside of the cabin, with images visible on the operator console, on an additional external monitor and also remotely.

The LS7 includes BLM Group’s Active Tools, which automatically adapt process parameters for optimal results independent of operator experience, ensuring the highest cutting precision and speed, according to company officials. Additionally, an Active Nozzle Changing feature automatically monitors cutting-nozzle wear and exchanges it based on the condition set within the controller.

Laser Cutting and Automation Team for High-Output Production

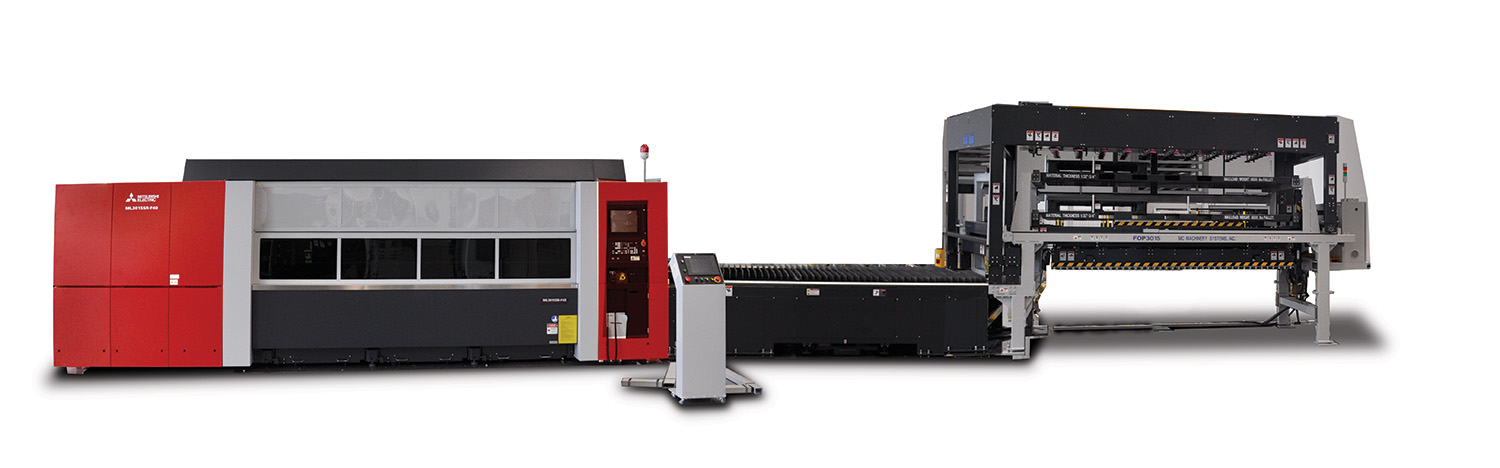

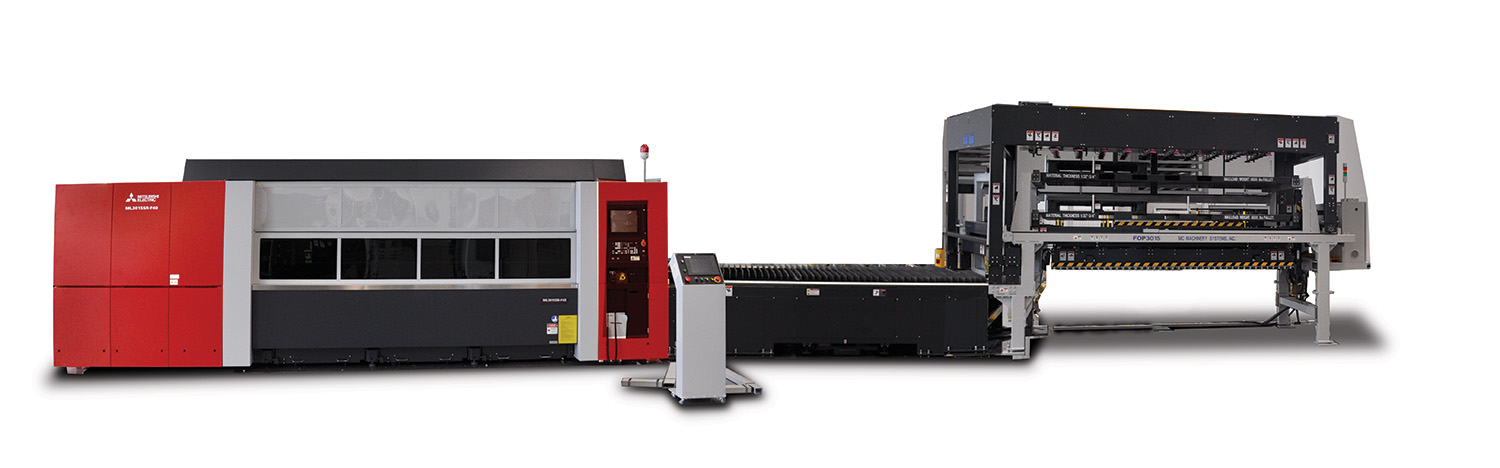

MC Machinery displayed the GX-F Advanced artificial intelligence (AI)-enabled 10- and 12-kW fiber laser cutting machines, equipped with state-of-the-art automation systems. The 12-kW machine—the newest addition to MC Machinery’s Mitsubishi Laser lineup—connected to the SmartFlex Element Type R automation system (pictured), while the 10-kw GX-F Advanced connected to the new Astes4 Skyway high-speed laser sorting system. To help ease concerns over the ongoing shortage of skilled manufacturing workers, the intuitive AI technology allows simplified use of the GX-F Advanced series for operators of all skill levels, offer company officials.

MC Machinery displayed the GX-F Advanced artificial intelligence (AI)-enabled 10- and 12-kW fiber laser cutting machines, equipped with state-of-the-art automation systems. The 12-kW machine—the newest addition to MC Machinery’s Mitsubishi Laser lineup—connected to the SmartFlex Element Type R automation system (pictured), while the 10-kw GX-F Advanced connected to the new Astes4 Skyway high-speed laser sorting system. To help ease concerns over the ongoing shortage of skilled manufacturing workers, the intuitive AI technology allows simplified use of the GX-F Advanced series for operators of all skill levels, offer company officials.

By integrating advanced gas-reduction technology, this series of laser cutting machines reportedly delivers more power while using as much as 77-percent less nitrogen than previous machines. It also reportedly offers high processing stability with improved beam-quality consistency; beam-cleaning and anti-reflection technologies; elimination of setup time between differing materials; low operating cost coupled with long consumables life; elimination of material scratching; optimized cutting speed; onsite or remote monitoring of the cutting process; and reduced piercing time.

As for the automation equipment displayed at FABTECH, the SmartFlex Element Type R features a small footprint that allows for use in limited production space where high-volume, lights-out capabilities are needed. The Astes4 Skyway high-speed laser sorting system reportedly is ideal for fabricators facing worker shortages and bottlenecks resulting from the increased productivity of higher-volume fiber lasers. Its modular sorting capability maximizes productivity and efficiency of downstream operations.

20 kW of Cutting Power, Plus Full Suite of Shop-Floor Software

Bystronic showcased its ByStar 3015 fiber laser cutting machine, which offers a reliable cutting process even at high laser outputs, through a wide range of applications and at high throughput, resulting in a low-cost part, according to company officials. The machine now is available with 20 kW of power.

Also on display, the compact, 12-kW BySmart Fiber machine, with optional Parameter Wizard and BeamShaper features to help deliver high part output across thin to medium sheet metal thicknesses. At FABTECH, the BySmart Fiber was paired with Bystronic’s ByTrans Extended material-handling automation.

And, Bystronic presented its BySoft Suite, which includes the following BySoft software products: BySoft Insight for analysis of historical data; BySoft Business that serves as the backbone of seamless data flow in a smart factory; BySoft Shop Floor that takes responsibility for operation of the shop floor and integrates business data with production data; BySoft CAD, which enables import and processing of all types of 3D-CAD data; BySoft CAM for efficient and intuitive development from the cutting plans for laser cutting machines; and BySoft Cell Control for status monitoring, and device or cell control through real-time network communication with machinery, the manufacturing process and those working in a cell.

Advanced 15-kW 2D Laser Cutting

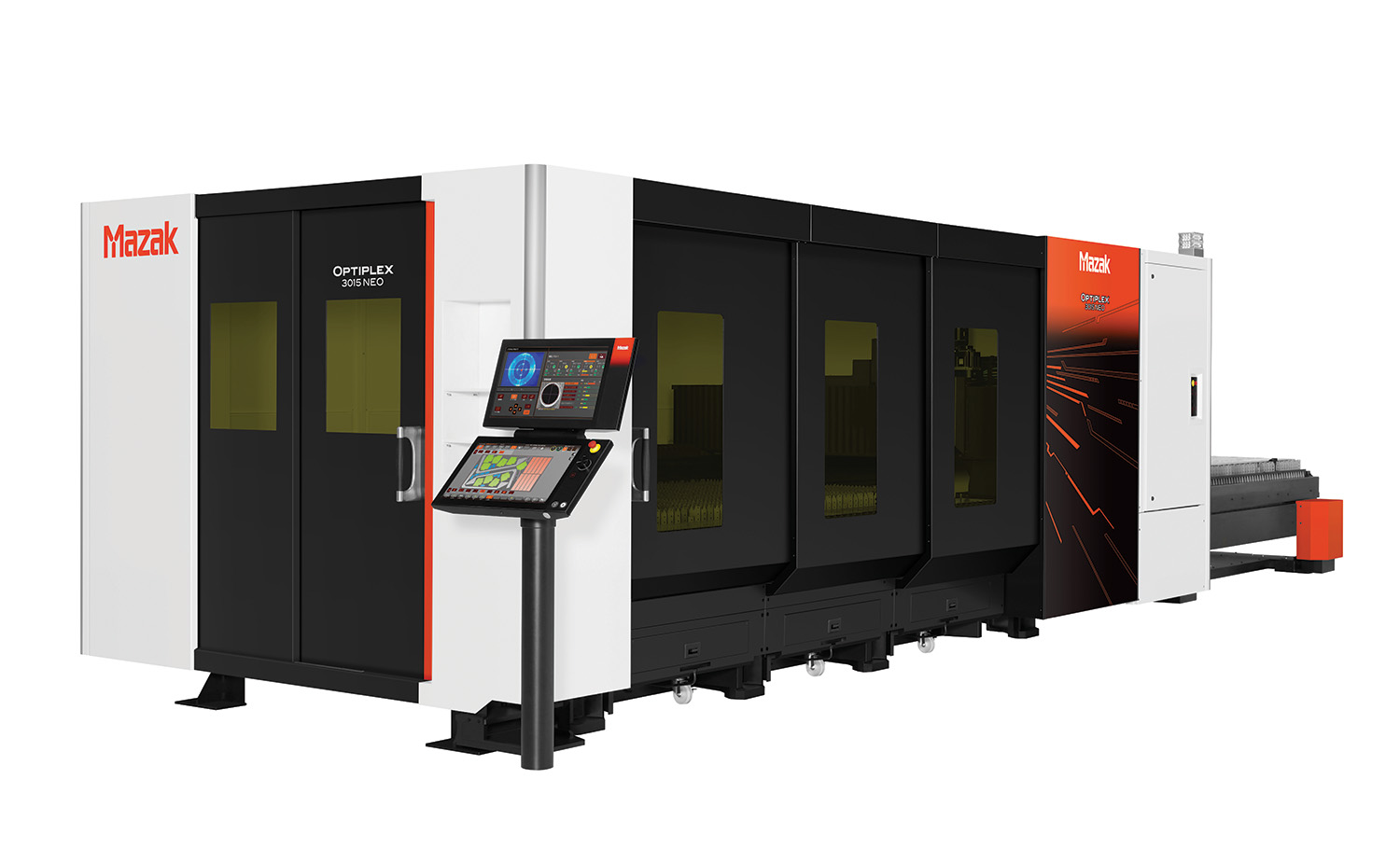

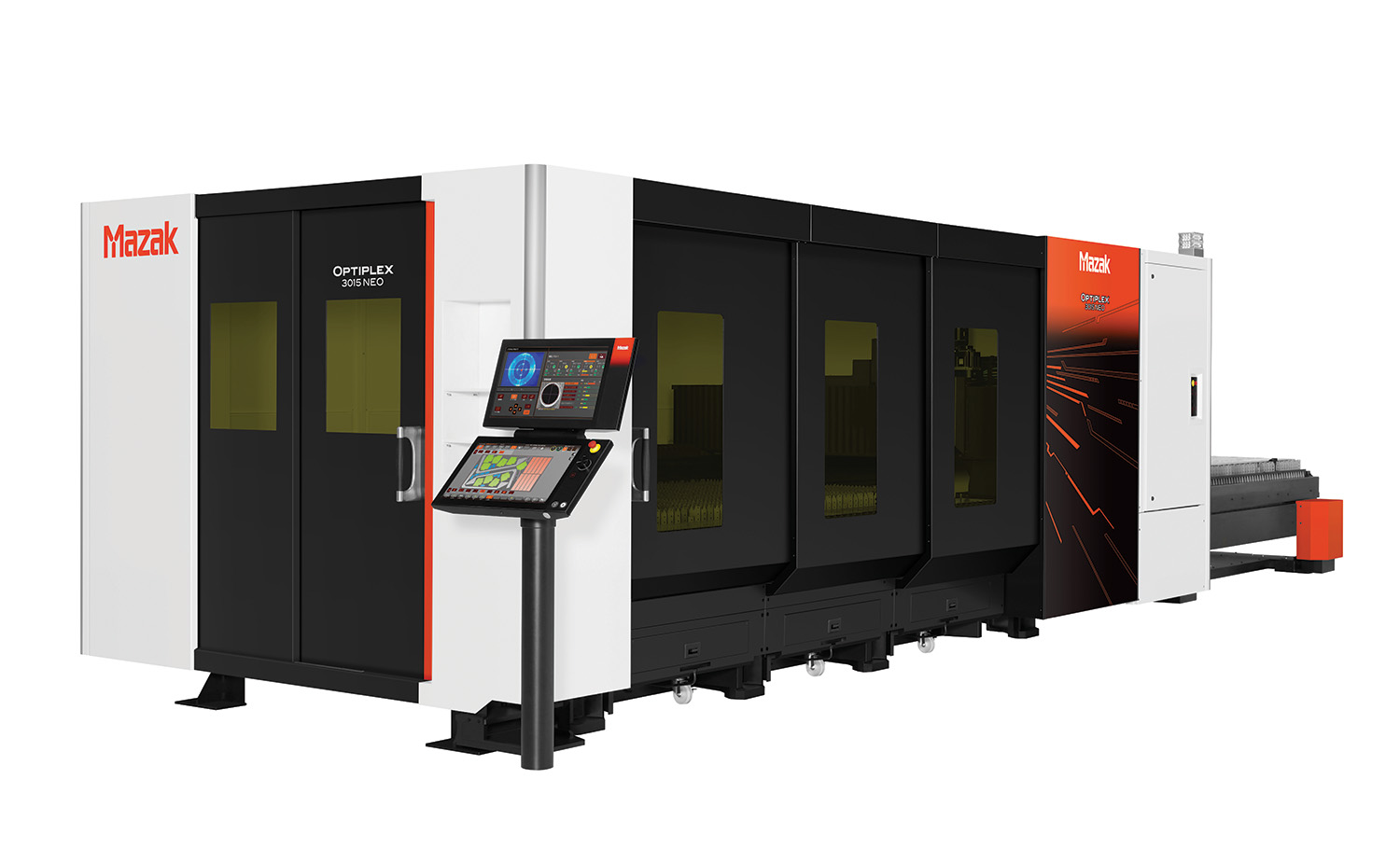

Mazak Optonics provided demos of its new Optiplex 3015 NEO 2D laser cutting machine, which features 15 kW of power, beam-shape/diameter control, an advanced torch head and a new series of nozzles.

The machine automatically adjusts beam diameter to optimally cut various materials, and beam shape to control beam concentration and power density. The result is improved cut speed and quality for a variety of materials, according to company officials. Other keys to machine performance include use of variable power distribution and the advanced Mazak MCT3 cutting head. All of this, officials explain, allow the 15-kW machine to deliver faster cutting speeds than machines offering even greater power levels, and significantly reduced cost of operation when employing high-pressure air cutting.

The machine automatically adjusts beam diameter to optimally cut various materials, and beam shape to control beam concentration and power density. The result is improved cut speed and quality for a variety of materials, according to company officials. Other keys to machine performance include use of variable power distribution and the advanced Mazak MCT3 cutting head. All of this, officials explain, allow the 15-kW machine to deliver faster cutting speeds than machines offering even greater power levels, and significantly reduced cost of operation when employing high-pressure air cutting.

For simple accessibility and ease of operation, the machine is equipped with large front and side access doors, and minimized work-area restrictions ease the loading of material onto the machine and the unloading of finished parts.

The new Mazatrol SmoothLx CNC control, with a 21.5-in. screen and touch panel, features dual monitors that allow simultaneous running of multiple applications. And, the CNC control rotates to give operators the flexibility to work at the front or side of the machine. This feature also allows flexible shop-floor placement of the machine, where walls may block views to the front or side. Simply rotate the control for the ideal viewing angle.

The Optiplex 3015 NEO comes equipped with a nozzle changer and nozzle-centering camera for visibility of nozzle location while making torch adjustments; camera-assisted part nesting, which automatically determines arrangement of parts for cutting on remnant material; and other high-technology setup, monitoring and cutting functions to support optimal laser-cutting performance.

Software Suite for Laser Cutting and Other Operations

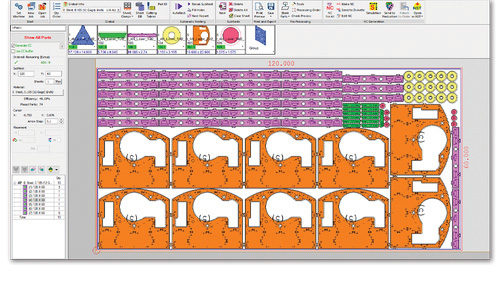

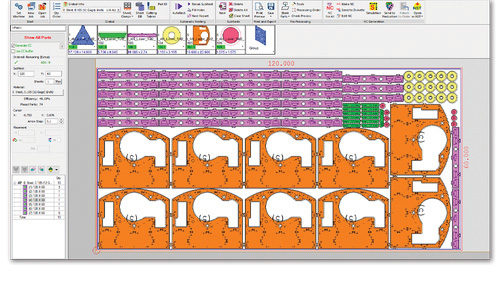

Cincinnati Inc. offered details on its Encompass software suite for laser cutting and other operations. The software is designed to help users move from the digital part to the physical part of everyday operations accurately and efficiently, according to company officials. The Encompass suite includes:

Cincinnati Inc. offered details on its Encompass software suite for laser cutting and other operations. The software is designed to help users move from the digital part to the physical part of everyday operations accurately and efficiently, according to company officials. The Encompass suite includes:

- Design—From 3D models, accurately import geometry and identify the correct flat blank.

- Nest—Amplify the ability to nest parts with software automation, and create optimized machine code to make Cincinnati cutting machines—and machines from most other manufacturers—operate optimally.

- Bend—Improve offline press brake programming with advanced software automation.

- Schedule—Automatically schedule multiple jobs across multiple shifts and multiple Cincinnati laser cutting machines.

- Automate—Simulation capability in this software for robot-tended press brake bending cells ensures collision-free solutions and the generation of efficient programs for the robot and the press brake.

- Analyze—Receive real-time and historical insight into the productivity of all Cincinnati machines anywhere from any device with CiberDash.

Laser or Plasma Cutting Machines Designed for Automated Production

Messer Cutting Systems touted its new Element 400L Unitized and Element 400 Gantry, U.S.-manufactured cutting machines featuring acceleration and speeds capable of supporting laser or plasma heads with virtually no loss in performance, according to company officials. Element 400 models can be equipped with customized options for plasma beveling, laser beveling and marking.

Messer Cutting Systems touted its new Element 400L Unitized and Element 400 Gantry, U.S.-manufactured cutting machines featuring acceleration and speeds capable of supporting laser or plasma heads with virtually no loss in performance, according to company officials. Element 400 models can be equipped with customized options for plasma beveling, laser beveling and marking.

These Element 400 lines offer an improved user experience via a Global Connect CNC control equipped with 18.5-in. touchscreen that presents a clear overview of all production data, and improved cutting quality due to premium construction components that provide smooth vibration-free tool-path movements from the helical rack-and-pinion drive systems.

Designed for strength, durability and precision, the Element 400L Unitized machine (pictured) offers customizable configurations and other features with automated production in mind, according to company officials. Fitted for plasma, laser, both plasma and laser bevel cutting, or oxyfuel cutting, the machine offers 6, 8 or 10 ft. of cutting width, and 10 to 40 ft. of cutting length plus park space for the machine. Users may select a Precitec ProCutter 2 laser cutting head, which auto focuses its position for maximum efficiency, and performs constant, high-cutting speeds at any operating temperature. The laser beam, completely sealed against microdust, provides power to 20 kW and a focal length of 150 or 200 mm with a zoom head. MF

Industry-Related Terms: Bending,

Blank,

Brass,

CAD,

Cam,

CNC (Computer Numerical Control),

LASER,

Lines,

Nesting,

Pallet,

Piercing,

Stainless SteelView Glossary of Metalforming Terms

See also: Prima Power North America, Inc., Mazak Optonics Corporation, MC Machinery Systems, Cincinnati Inc., Amada North America, Inc

Technologies: Cutting

The self-monitoring Regius 3015 AJ linear fiber laser cutting machine (pictured) features a high-speed three-axis linear drive and new processing technology. Designed for autonomous operation, it integrates intelligent features and functions, including lens monitoring, collision recovery, automatic head recovery, and automated nozzle change and centering. As a result, machine and process parameters automatically are adjusted according to the needs of the current cutting operation. To aid in efforts toward zero downtime, the machine can detect cutting failure and engage collision recovery via its i-Nozzle checker with nozzle changer. Pairing it with AMS 3015 LL (Linear Loading) automation (as displayed in the Amada booth) further enhances productivity while maximizing the use of valuable floor space, note company officials.

The self-monitoring Regius 3015 AJ linear fiber laser cutting machine (pictured) features a high-speed three-axis linear drive and new processing technology. Designed for autonomous operation, it integrates intelligent features and functions, including lens monitoring, collision recovery, automatic head recovery, and automated nozzle change and centering. As a result, machine and process parameters automatically are adjusted according to the needs of the current cutting operation. To aid in efforts toward zero downtime, the machine can detect cutting failure and engage collision recovery via its i-Nozzle checker with nozzle changer. Pairing it with AMS 3015 LL (Linear Loading) automation (as displayed in the Amada booth) further enhances productivity while maximizing the use of valuable floor space, note company officials.

Prima Power featured the Laser Genius+ with Compact Server, developed to cut large and heavy workpieces precisely and at high speeds. Rated to a trajectory speed of 180 m/min. and acceleration of 2.8 g, the 2D-cutting machines come in three sizes and with a range of laser powers to satisfy a variety of application needs. Maximum X-Y-axis travel: 6320 by 2200 mm. Integrated software modules simplify processes, and artificial-intelligence algorithms provide advanced monitoring and process-control functions.

Prima Power featured the Laser Genius+ with Compact Server, developed to cut large and heavy workpieces precisely and at high speeds. Rated to a trajectory speed of 180 m/min. and acceleration of 2.8 g, the 2D-cutting machines come in three sizes and with a range of laser powers to satisfy a variety of application needs. Maximum X-Y-axis travel: 6320 by 2200 mm. Integrated software modules simplify processes, and artificial-intelligence algorithms provide advanced monitoring and process-control functions.  BLM Group unveiled its latest lineup addition, the LS7 sheet laser cutting machine, designed as an entry-level product in the high-end system segment, according to BLM Group officials, and capable of employing laser power to 12 kW.

BLM Group unveiled its latest lineup addition, the LS7 sheet laser cutting machine, designed as an entry-level product in the high-end system segment, according to BLM Group officials, and capable of employing laser power to 12 kW. MC Machinery displayed the GX-F Advanced artificial intelligence (AI)-enabled 10- and 12-kW fiber laser cutting machines, equipped with state-of-the-art automation systems. The 12-kW machine—the newest addition to MC Machinery’s Mitsubishi Laser lineup—connected to the SmartFlex Element Type R automation system (pictured), while the 10-kw GX-F Advanced connected to the new Astes4 Skyway high-speed laser sorting system. To help ease concerns over the ongoing shortage of skilled manufacturing workers, the intuitive AI technology allows simplified use of the GX-F Advanced series for operators of all skill levels, offer company officials.

MC Machinery displayed the GX-F Advanced artificial intelligence (AI)-enabled 10- and 12-kW fiber laser cutting machines, equipped with state-of-the-art automation systems. The 12-kW machine—the newest addition to MC Machinery’s Mitsubishi Laser lineup—connected to the SmartFlex Element Type R automation system (pictured), while the 10-kw GX-F Advanced connected to the new Astes4 Skyway high-speed laser sorting system. To help ease concerns over the ongoing shortage of skilled manufacturing workers, the intuitive AI technology allows simplified use of the GX-F Advanced series for operators of all skill levels, offer company officials. The machine automatically adjusts beam diameter to optimally cut various materials, and beam shape to control beam concentration and power density. The result is improved cut speed and quality for a variety of materials, according to company officials. Other keys to machine performance include use of variable power distribution and the advanced Mazak MCT3 cutting head. All of this, officials explain, allow the 15-kW machine to deliver faster cutting speeds than machines offering even greater power levels, and significantly reduced cost of operation when employing high-pressure air cutting.

The machine automatically adjusts beam diameter to optimally cut various materials, and beam shape to control beam concentration and power density. The result is improved cut speed and quality for a variety of materials, according to company officials. Other keys to machine performance include use of variable power distribution and the advanced Mazak MCT3 cutting head. All of this, officials explain, allow the 15-kW machine to deliver faster cutting speeds than machines offering even greater power levels, and significantly reduced cost of operation when employing high-pressure air cutting. Cincinnati Inc. offered details on its Encompass software suite for laser cutting and other operations. The software is designed to help users move from the digital part to the physical part of everyday operations accurately and efficiently, according to company officials. The Encompass suite includes:

Cincinnati Inc. offered details on its Encompass software suite for laser cutting and other operations. The software is designed to help users move from the digital part to the physical part of everyday operations accurately and efficiently, according to company officials. The Encompass suite includes: Messer Cutting Systems touted its new Element 400L Unitized and Element 400 Gantry, U.S.-manufactured cutting machines featuring acceleration and speeds capable of supporting laser or plasma heads with virtually no loss in performance, according to company officials. Element 400 models can be equipped with customized options for plasma beveling, laser beveling and marking.

Messer Cutting Systems touted its new Element 400L Unitized and Element 400 Gantry, U.S.-manufactured cutting machines featuring acceleration and speeds capable of supporting laser or plasma heads with virtually no loss in performance, according to company officials. Element 400 models can be equipped with customized options for plasma beveling, laser beveling and marking.