Five-Axis AP&T SpeedFeeders Automate Tandem Line at Spartanburg Steel

June 28, 2022Comments

Spartanburg Steel Products Inc., Spartanburg, SC,

a manufacturer of stamped parts and assemblies for cars, trucks and

agricultural machinery, has automated a five-press tandem line to shorten cycle

times and increase flexibility. Rather

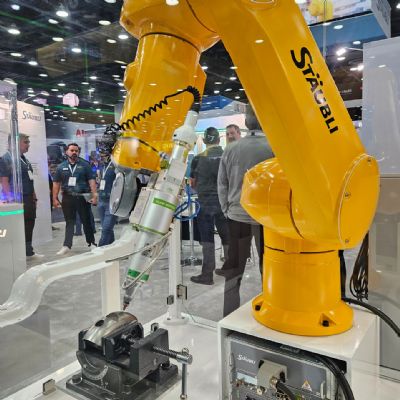

than use conventional industrial robots to automate the line, the firm opted

for a solution based on the newest generation of five-axis SpeedFeeders from

AP&T North America.

Spartanburg Steel Products Inc., Spartanburg, SC,

a manufacturer of stamped parts and assemblies for cars, trucks and

agricultural machinery, has automated a five-press tandem line to shorten cycle

times and increase flexibility. Rather

than use conventional industrial robots to automate the line, the firm opted

for a solution based on the newest generation of five-axis SpeedFeeders from

AP&T North America.

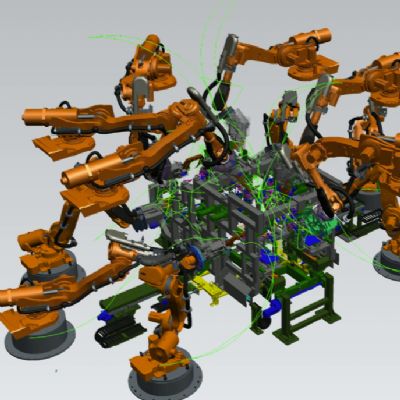

“In total, we installed six SpeedFeeders for blank feeding, transfer of parts between the five presses, and unloading,” says Adam Allansson, president of AP&T North America. “As we were doing our work, Spartanburg Steel upgraded the presses in the line and its tool-exchange system. We cooperated closely with other suppliers to ensure the best possible total solution in the shortest possible time.”

Since the fall of 2019, the upgraded five-press tandem line has delivered according to expectations. It is regularly serviced by AP&T technicians, and new staff at Spartanburg Steel have been trained in operation and safety by AP&T.

“We installed the automation to improve safety on the line,” says Chad Raynes, vice president of business development and engineering at Spartanburg Steel. “This also has resulted in better efficiency at a lower cost. We plan to automate additional lines in the future, specifically a tandem line in 2023.”

See also: AP&T North America Inc.

Technologies: Pressroom Automation